High intensity thermosetting molecule based composite material and application thereof

A composite material and polymer-based technology, applied in the field of composite materials, can solve the problems of softening and wear resistance, decreased service life, uneven strength, etc., achieve accurate and stable molding dimensions, reduce railway maintenance, strength and mold. high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

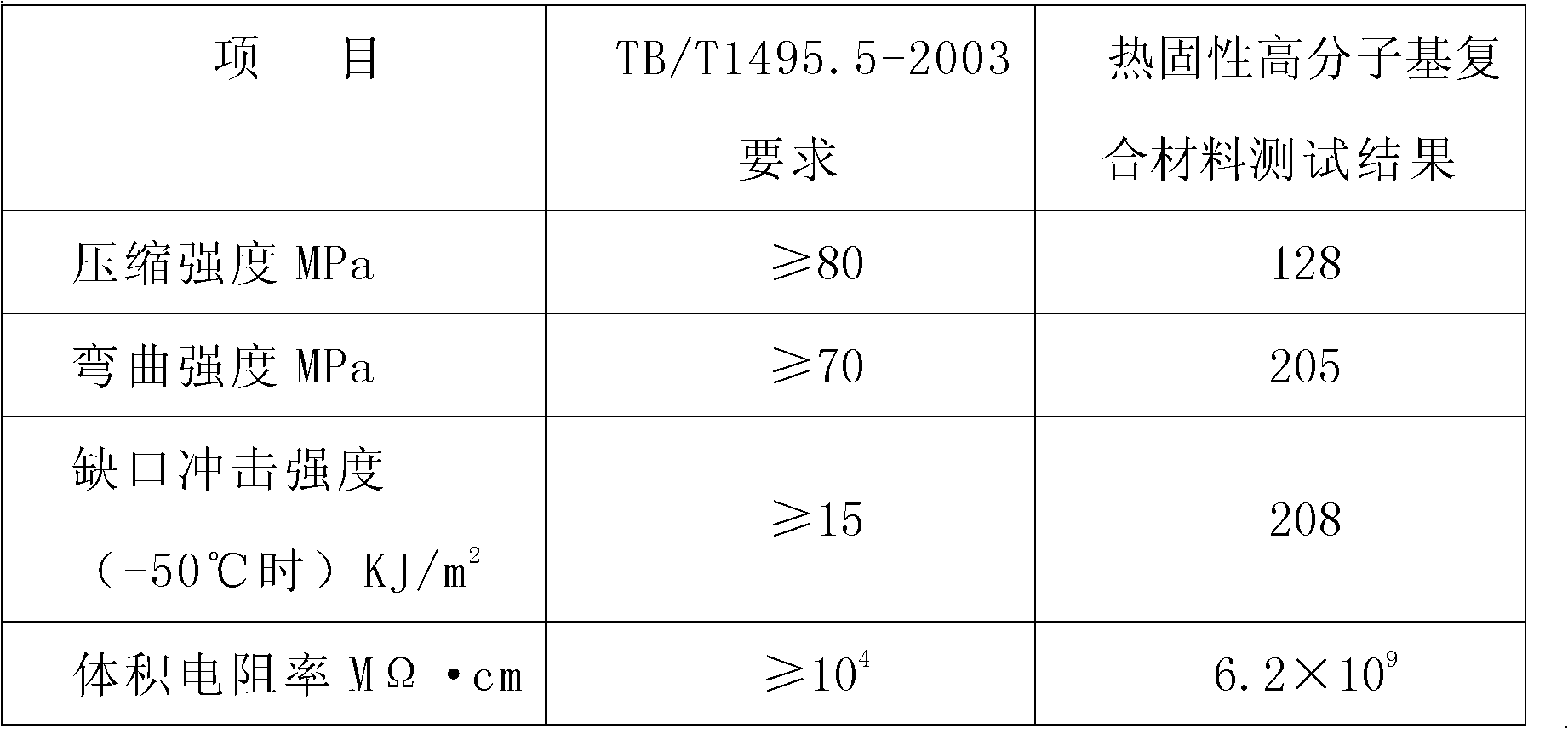

Embodiment 1

[0016] The high-strength thermosetting polymer-based composite material prepared by the die-casting method described in this example is to prepare a high-strength polymer thermosetting resin-modified epoxy resin and granular reinforcing material additives-carbon black, hollow microspheres , mica powder, ground into a uniform slurry, and after stirring evenly, add the curing crosslinking agent according to the ratio of 2:1 between the polymer thermosetting high-strength resin and the curing crosslinking agent, and infiltrate the quantitative fibrous reinforcing material——glass fiber, at 100 After pre-curing at -120°C for 20-40 minutes, the prepreg was prepared. The prepreg was quantitatively placed in the heated railway track fastener mold, and after exhausting, the pressure was 1000KN, and the temperature was controlled at 165-175°C. After 3 -After 6 minutes of post-curing molding, the fastener is made by a molding process. In terms of parts by weight, the fibrous reinforcing ...

Embodiment 2

[0018] The high-strength thermosetting polymer-based composite material described in this embodiment is to prepare a high-strength polymer thermosetting resin-modified epoxy resin and granular reinforcing material additives-carbon black, silicon dioxide, and mica powder in a prescribed proportion. , ground into a uniform slurry, after stirring evenly, add the curing cross-linking agent according to the weight ratio of the polymer thermosetting high-strength resin and the curing cross-linking agent in a ratio of 2:1, and after soaking and pre-curing at 100-120 ° C, the quantitative fibrous reinforcement Material - the combination of glass fiber and carbon fiber is continuously pultruded at a uniform speed (effective curing time is 3-6 minutes) through a weft heating mold (control temperature 165-175°C, tension 80-120KN), and the weft dimension is consistent after heat preservation and hardening The strips are cut according to a certain size and then shaped to obtain the fastener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com