Modified thermosetting ultra-high polymer epoxy resin railroad track elastic bar insulation gauge block

An epoxy resin and ultra-high polymer technology, applied in the direction of fixed rails, rails, roads, etc., can solve the problems of uneven strength, failure to meet strength requirements, backward technology, etc., to avoid linear expansion coefficient and excellent mechanical properties. , the effect of uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

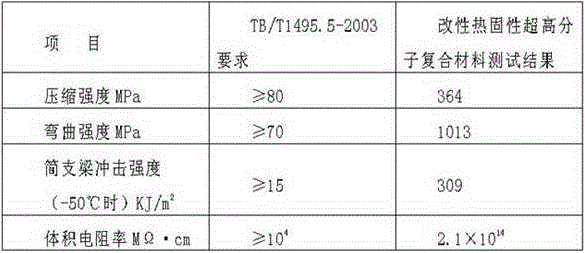

[0014] Embodiment 1: a modified thermosetting ultra-high polymer epoxy resin railway track elastic strip Type III insulating gauge block, characterized in that it contains 12-18% by weight of modified thermosetting epoxy resin, 4-6% by weight 60-86% by weight of fibrous reinforcing material, 5.5-8.5% by weight of powder reinforcing material additive, the sum of the amount of the above components is 100%.

[0015] The modified thermosetting epoxy resin contains 14-16% (14% or 14.8% or 15% or 15.5% or 16%) of bisphenol A epoxy resin and 0.15-0.25% (0.15% or 0.2% or 0.25%) by weight of polyether-modified methyltetrahydrophthalic anhydride toughener; the 14-16% by weight of bisphenol A epoxy resin is composed of E-51 epoxy resin and E-44 ring Oxygen resin is formed in a ratio of 2:1; the hyperbranched imidazole amidated derivative curing agent is made of trimethylolpropane 15-20% (15% or 16% or 17% or 18% or 19% or 20%), 2,2-dimethylolpropionic acid 15-21% (15% or 16% or 17% or 1...

Embodiment 2

[0019] Embodiment 2: On the basis of embodiment 1, the modified thermosetting epoxy resin containing 15% by weight, the hyperbranched curing crosslinking agent of 5% by weight, the fibrous reinforcing material of 73% by weight, 7% by weight powder reinforcement additives.

Embodiment 3

[0020] Embodiment 3: On the basis of Embodiment 1 or 2, a method for preparing a modified thermosetting ultra-high molecular epoxy resin railway track elastic strip III type insulating gauge block, 12-18% by weight of modified thermosetting Epoxy resin and 5.5-8.5% by weight of powder reinforcing material additives are mixed and ground into a uniform slurry, and 4-6% by weight of hyperbranched curing cross-linking agent is added in proportion and stirred evenly, and then soaked in a quantitative 60-86 % by weight fiber reinforced material to make a thick paste or paste prepreg with a viscosity of 50000-100000Pa.s, the sum of the above components is 100%, and then the prepreg is placed in a heated mold, After exhausting, apply a pressure of more than 1000KN, control the temperature at 165-175°C, and undergo secondary curing for 3-6 minutes to obtain the finished modified thermosetting ultra-high polymer epoxy resin elastic strip type III insulating gauge block for railway tracks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com