CrNiMo series easily cut pinion steel and manufacturing method thereof

A gear steel, easy-cutting technology, applied in the field of metallurgy, can solve the problems of poor cutting performance of CrNiMo gear steel, achieve low cost and improve cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the production of CrNiMo series free-cutting gear steel;

[0038] Firstly, the primary molten steel is melted in the primary smelting furnace, and the steel is tapped in the range of 1600°C to 1650°C, and synthetic slag and pre-deoxidizer are added; secondly, the molten steel is refined in the ladle refining furnace to reduce [O] in the molten steel and the content of inclusions, the temperature is controlled at 1550 ° C ~ 1650 ° C, and the smelting time is within 60 minutes; then the molten steel is vacuum treated on the vacuum furnace, the vacuum degree is less than 76Pa, and the vacuum holding time is 15 ~ 35min. Argon gas is blown into the bottom; finally, continuous casting is carried out under full protection, and after heating for 1.5-4 hours, the slab is hot-rolled at 1180-1260°C into Φ30-160mm round steel.

[0039] See Table 1 to Table 5 for specific parameters. Numbering 1-3 corresponds to the steel type of embodiment 1-3,

[0040] Table 1 gear...

Embodiment 2

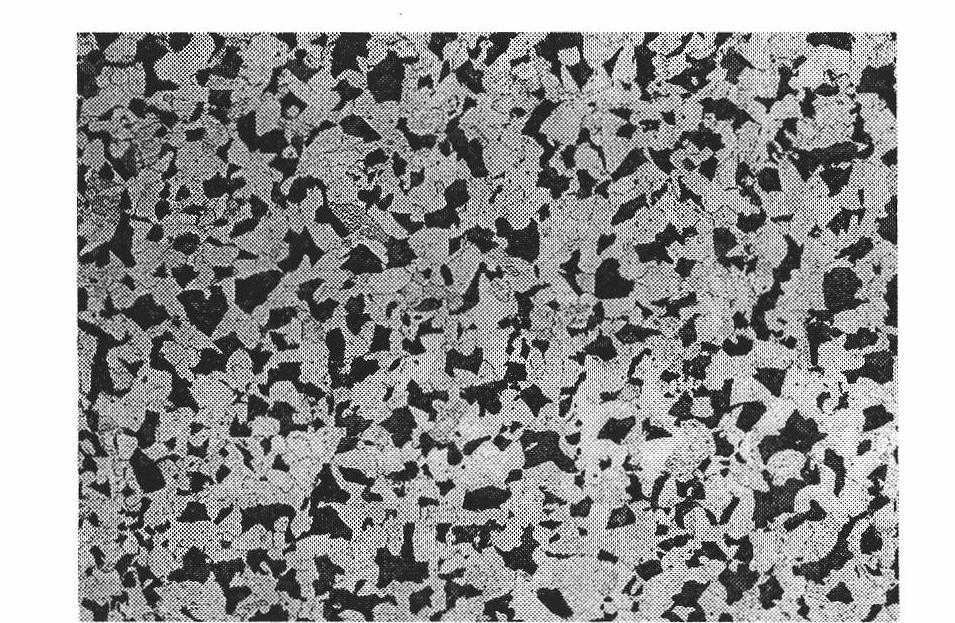

[0050] Example 2: Physical properties of steel

[0051] The hardenability of gear steel was determined according to GB / T 225 method, and the high-magnification inspection of gear steel was carried out according to GB / T 13299 method; the strength of gear steel was determined according to GB / T 228; the measurement results are shown in Table 3.

[0052] Table 6 Physical properties of steel

[0053]

[0054] Table 7 rough machining tool life test data table

[0055]

[0056] Table 8 Finishing tool life test data table

[0057]

[0058] It can be seen from Tables 6 to 8 that the gear steel of the present invention has stable hardenability control, good strength and toughness, and is equivalent to existing products and technologies. Its main advantages lie in maintaining high hardenability and good strength. On the basis of toughness, its cutting performance is significantly improved compared with existing products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com