Method for extruding and strengthening 7B50-T7751 aluminum alloy thick plate holes

A 7B50-T7751, plate hole technology, applied in the field of aluminum alloy surface strengthening, to achieve the effect of improving fatigue performance, reducing design requirements, and improving notch sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

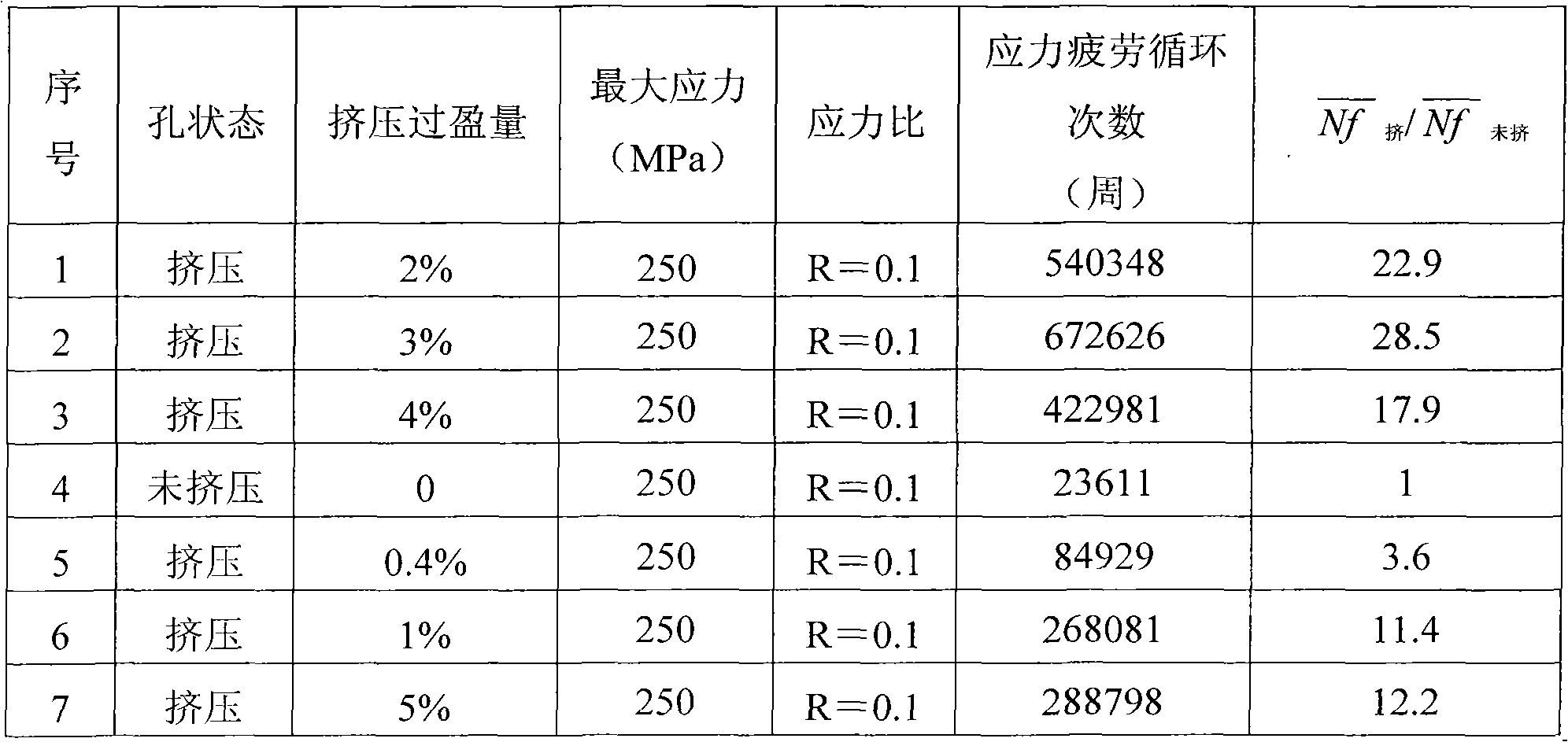

[0012] This kind of 7B50-T7751 thick plate hole extrusion strengthening method, the chemical composition and weight percentage of 7A55 aluminum alloy are shown in Table 1, the heat treatment system of 7B50 thick plate parts is T7751, and the smoothness of the hole wall surface is Ra1.6. A tapered metal mandrel is inserted into the hole, and mechanical pressure is applied to the end of the mandrel, so that the largest diameter part of the mandrel passes through the hole of the workpiece and then the pressure is stopped. The extrusion amount is 2 to 4%. The so-called extrusion The amount refers to the percentage of the deformation of the hole diameter of the workpiece to the original diameter of the hole. The hole edge distance of the workpiece hole is ≥1.7. The so-called hole edge distance refers to the ratio of the nearest distance from the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com