High-power semiconductor laser polarization coupling device and coupling method thereof

A coupling device and semiconductor technology, which is applied in the direction of semiconductor laser devices, laser devices, devices for controlling laser output parameters, etc., can solve the problems of output laser brightness and beam quality difficulties, and achieve improved beam quality and optical power density, high brightness and high Effect of Power Laser Output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

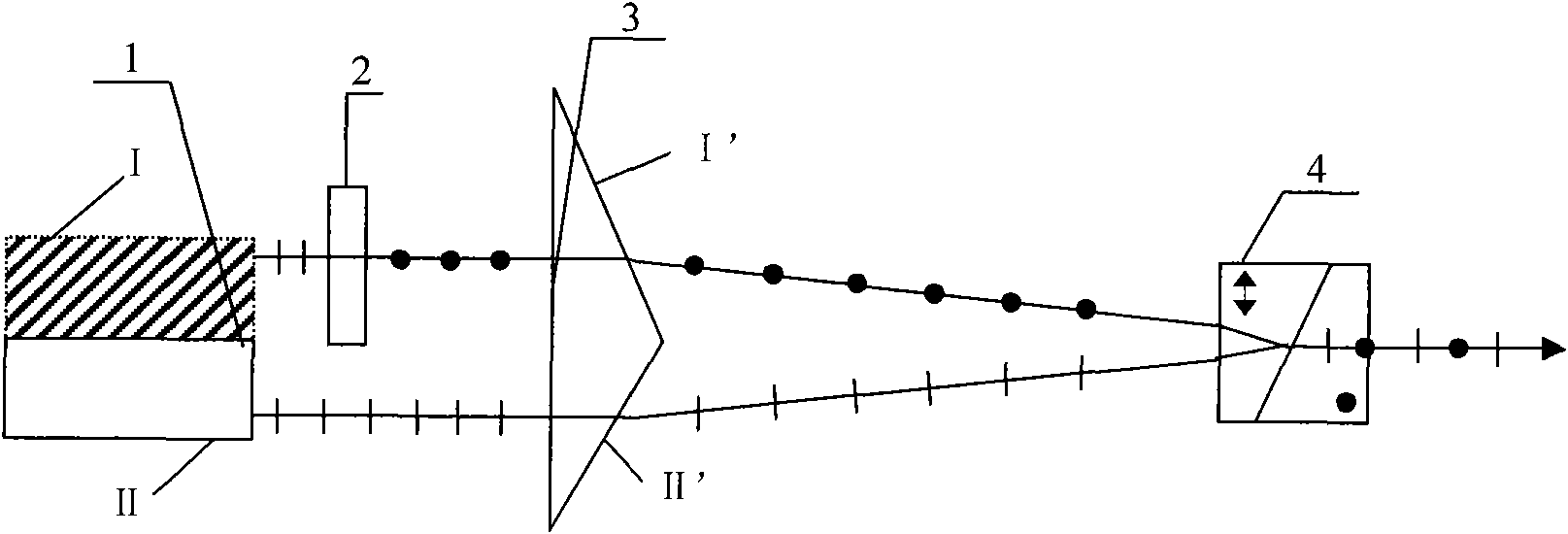

[0024] figure 1 The half-wave plate 2 is placed between the half beam I of the laser light emitted by the semiconductor laser and the side I' of the beam splitting and deflecting prism 3, wherein the lower end of the half-wave plate 2 is placed at the beam splitting deflecting prism. On the central line of the prism 3; half the light beam I of the laser light emitted by the semiconductor laser is p light (polarization direction parallel to the polarized light on the paper) before passing through the half wave plate 2, and after passing through the half wave plate 2 The polarization direction changes by π / 2, and becomes s light (polarized light whose polarization direction is perpendicular to the paper), and half of the laser light beam II emitted by the semiconductor laser is p light. After passing through the deflection prism, a beam of s light and a beam of p light After the light is incident on the Wollaston prism 4, a beam of partially polarized parallel light is synthesiz...

Embodiment 2

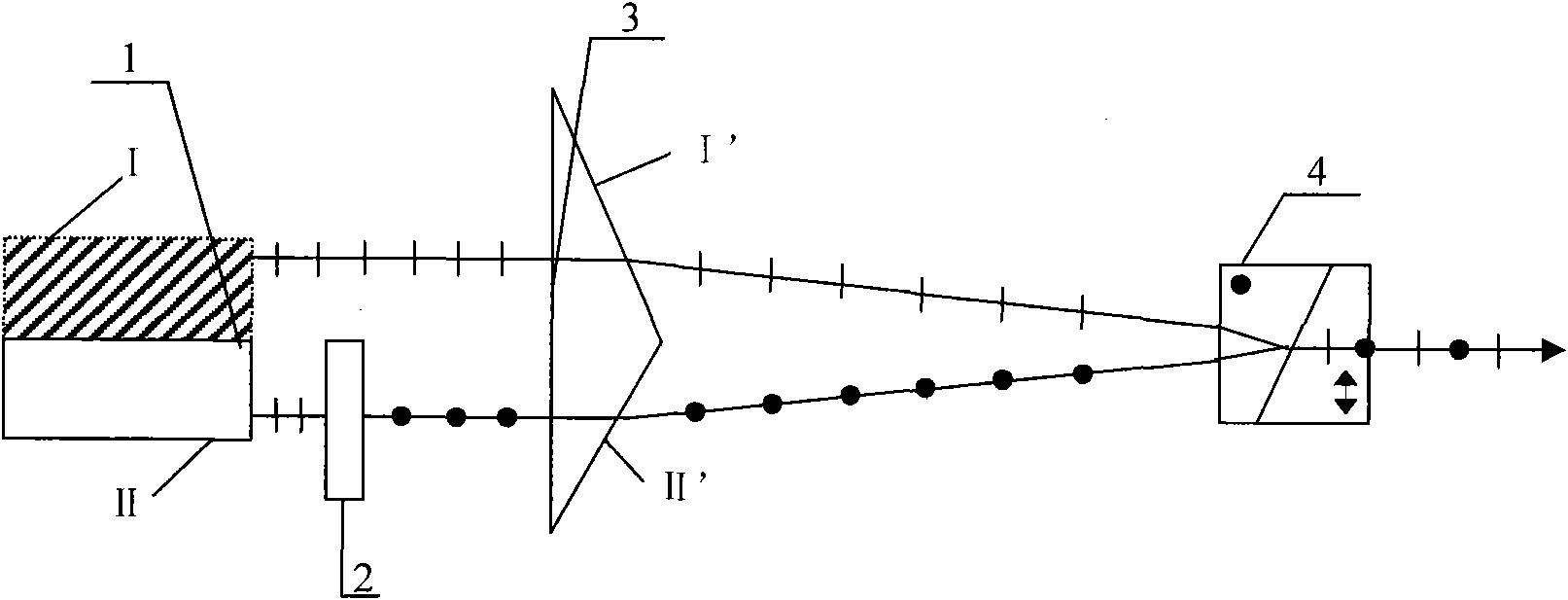

[0026] figure 2 The half-wave plate 2 is placed between the half beam II of the laser light emitted by the semiconductor laser and the side II' of the beam splitting deflection prism 3, wherein the upper end of the half-wave plate 2 is placed at the beam splitting deflection On the central line of the prism 3; half beam I of the laser light emitted by the semiconductor laser is p light, half of the light beam II of the laser light emitted by the semiconductor laser is p light before passing through the half wave plate 2, and passes through the half wave plate After 2, the polarization direction changes by π / 2 to become s light. After passing through the deflection prism, a beam of s light and a beam of p light enter Wollaston prism 4 and then synthesize a beam of partially polarized parallel light to exit, wherein Wollaston The crystal material used in the Raston prism is a negative uniaxial crystal.

Embodiment 3

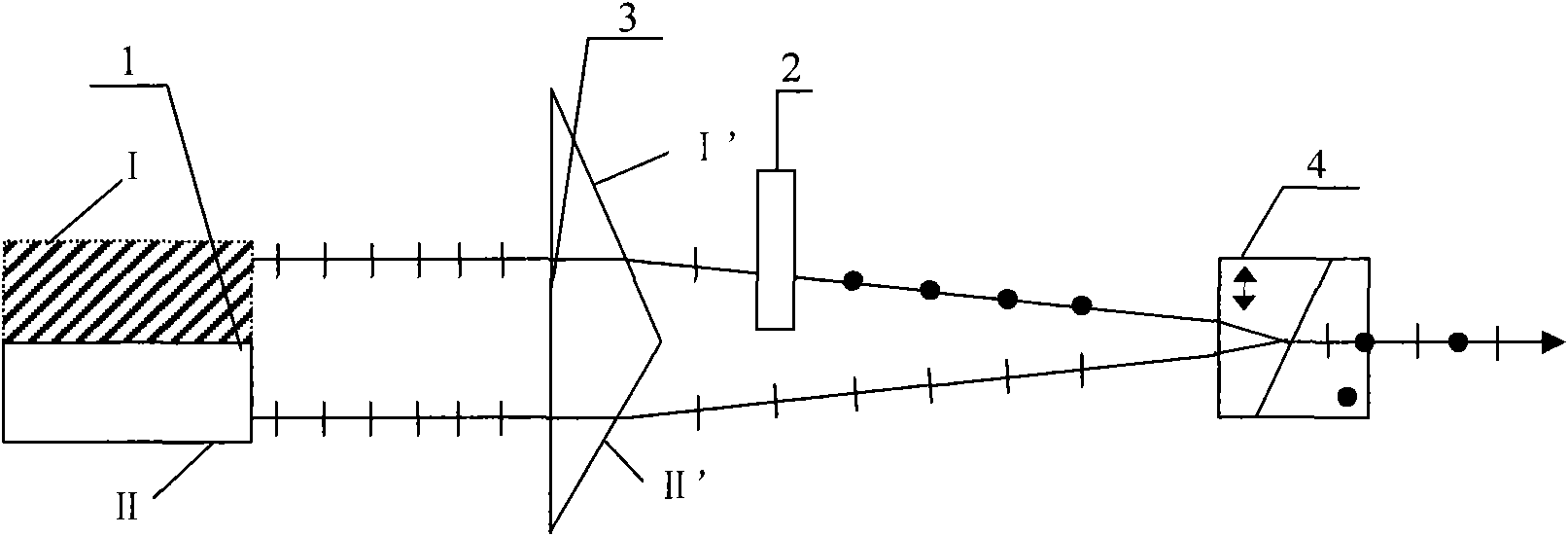

[0028] image 3 For the situation that the half-wave plate 2 is placed between the side I' of the beam splitting deflection prism 3 and the Wollaston prism 4, wherein the lower end of the half wave plate 2 is positioned at the side of the beam splitting deflection prism 3 On the central line, this situation is the same as the principle of embodiment 1;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com