Corrosive solution composition, corrosion method and generated silicon wafer

A technology for etching solutions and compositions, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve problems such as affecting product quality, blackening and dyeing, and achieve the effect of maintaining stable corrosion rate and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

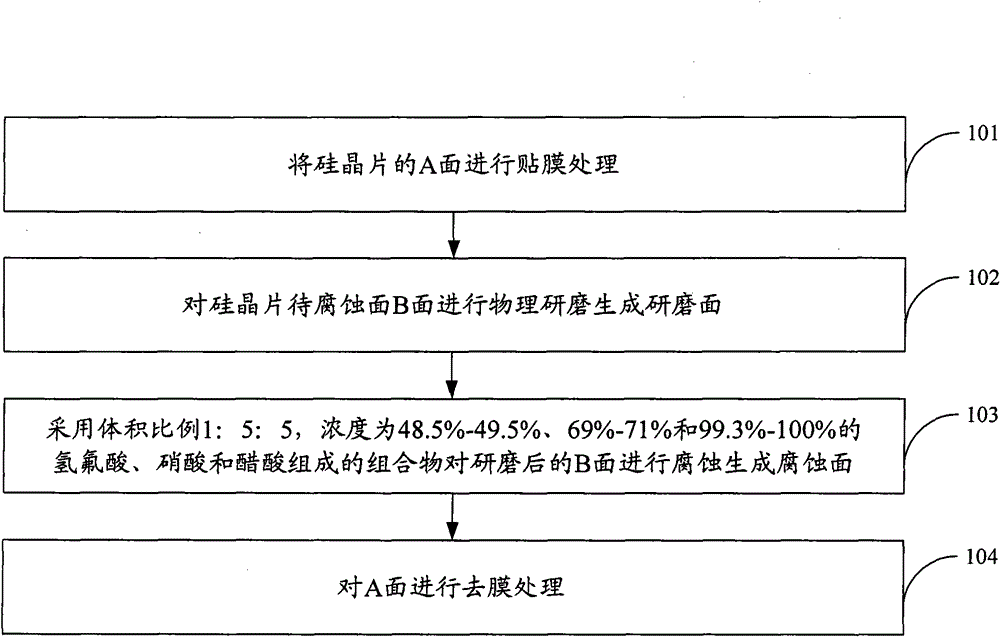

Image

Examples

Embodiment Construction

[0011] In order to solve the problem in the prior art that a silicon dioxide layer is formed on the corroded surface of the wafer after silicon corroding, which affects the quality of the product, an embodiment of the present invention provides a composition of etching solution, which is composed of hydrofluoric acid, nitric acid and acetic acid composition. Among them, the concentration of hydrofluoric acid is 48.5%-49.5%, the concentration of nitric acid is 69%-71%, and the concentration of acetic acid is 99.3%-100%. Of course, acetic acid CH3COOH is only a preferred solution in this embodiment, and other weak acids such as carbonic acid H2CO3, boric acid H3BO3 and weakly acidic organic acids can also be used. A preferred solution in this embodiment is that the volume ratio of hydrofluoric acid, nitric acid and acetic acid is 1:5:5, and the surface to be etched of the silicon crystal is etched, and the specific reaction process is as follows:

[0012] Si+4HNO 3 → SiO 2 +2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com