Method and arrangement to enhance the preheating of a fuel cell system

A fuel cell system and fuel cell technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of space occupation, explosion, high equipment cost, etc., and achieve energy cost reduction, high-efficiency heat transfer, The effect of heat transfer saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

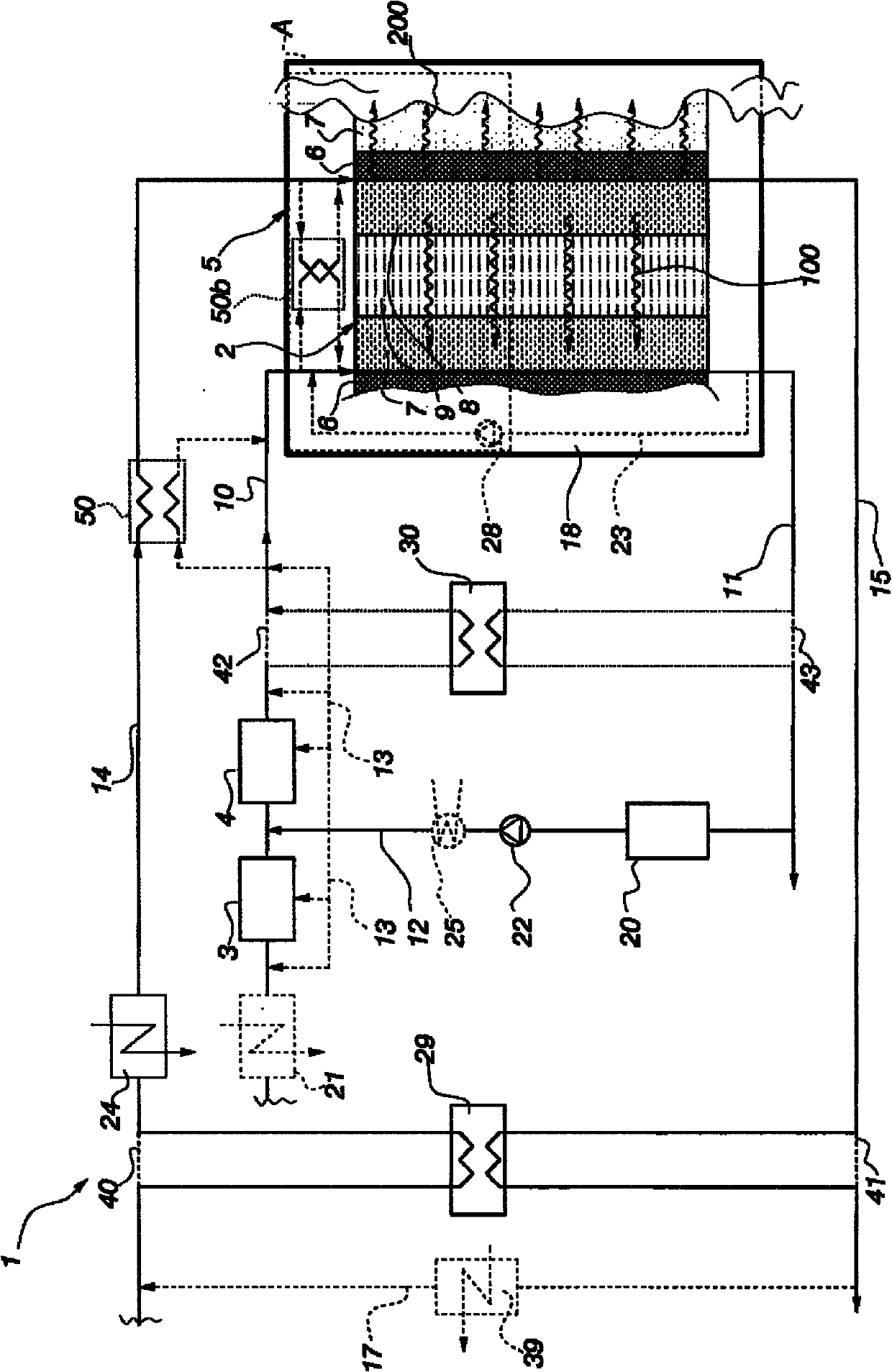

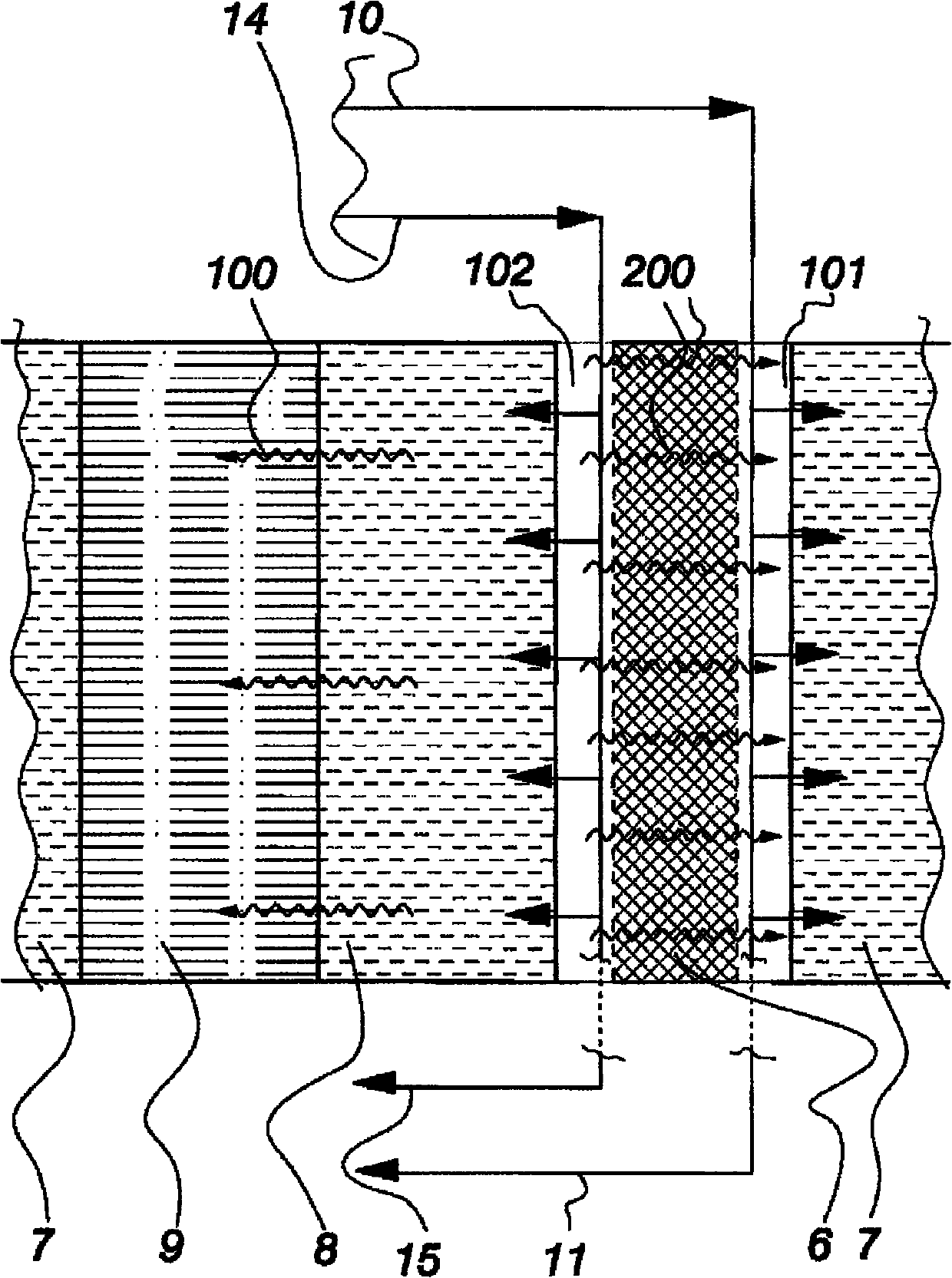

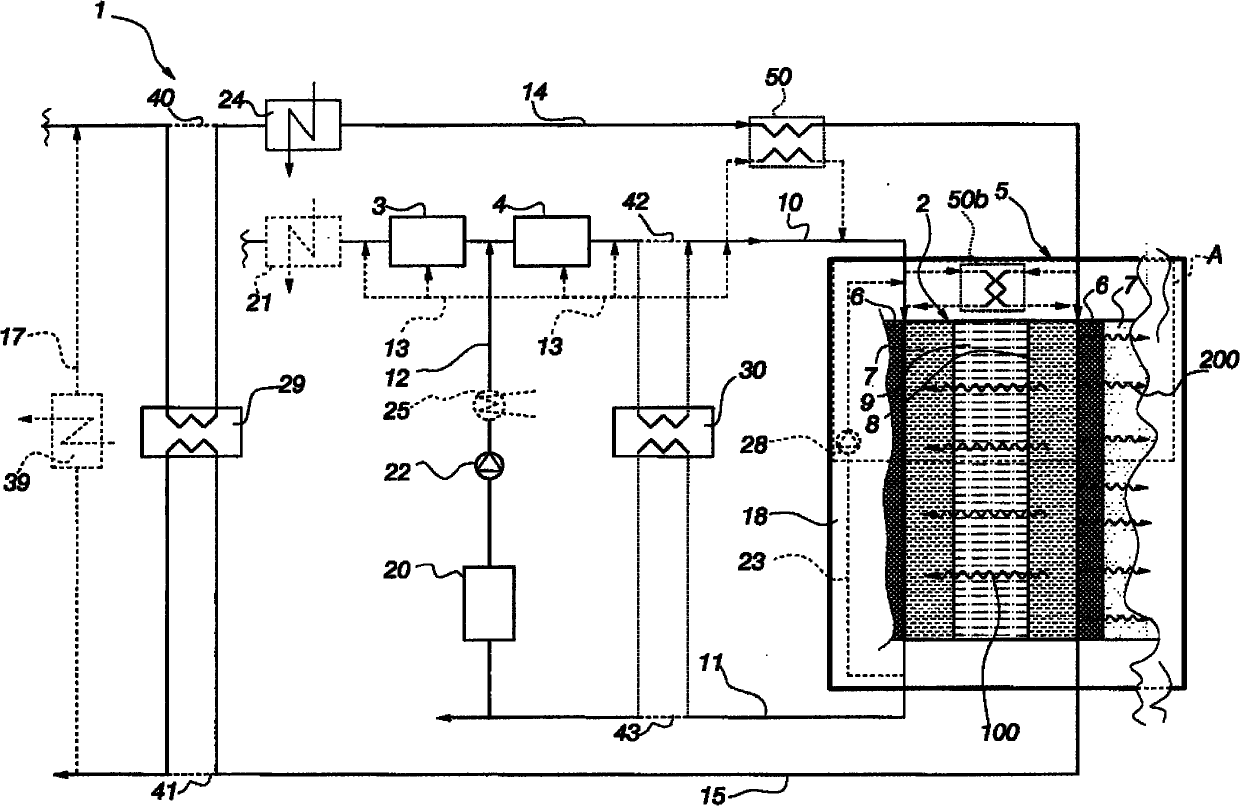

[0012] figure 1 The fuel cell system 1 is shown in a highly schematic view. The fuel cell unit 5 included in the fuel cell system 1 includes one or more fuel cell stacks consisting of fuel cells 2 connected continuously in series and connection plates 6 called interconnects provided between the individual fuel cells. , the fuel cell 2 is characterized by an anode side 7 , a cathode side 8 and an electrolyte 9 arranged between the anode side 7 and the cathode side 8 . The connecting plate 6 is preferably designed as a kind of bipolar plate, i.e. it is located on the cathode side of one individual fuel cell 2 and on the anode side of the other individual fuel cell 2, and acts as a link between the fuel cells between them. It acts as an electrical conductor between cells and as a gas barrier that blocks the uncontrolled flow of gas between cells. Most importantly, however, it provides a flow channel system on both the anode side and the cathode side for the gas to flow in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com