Integrated device for removal of dusts and gaseous pollutants

A pollutant removal technology, applied in the direction of air quality improvement, chemical instruments and methods, separation of dispersed particles, etc., can solve the problems of easy dust clogging, large waste, high investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

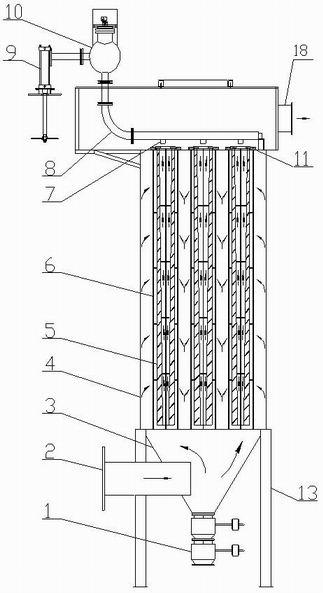

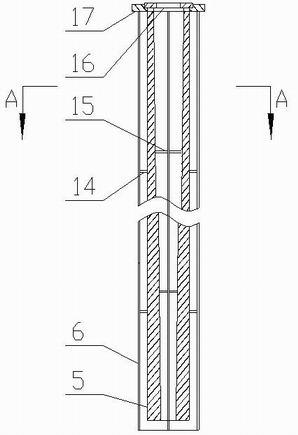

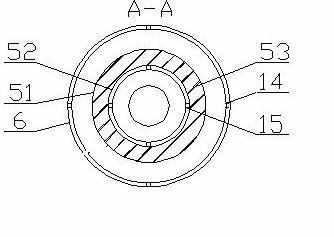

[0018] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, an integrated dust removal and gaseous pollutant removal device includes a bracket 13 and a bag filter. The bag filter is composed of ash cleaning device, box body 4, ash bin 3 and ash unloading device 1 from top to bottom. Several vertically installed filter bags 6 are arranged in the box body 4 . The cylindrical filter bag 6 is made of glass fiber filter material, the filter bag 6 is supported by a filter bag support cage 14, and the filter bag support cage 14 is surrounded by circular steel bars and vertical steel bars to form a cage structure. A filter bag cover 17 is welded on the top of the filter bag 6, and the filter bag cover 17 is placed on the flower plate 11 of the box body 4, and the filter bag 6 is pulled out from the top by carrying the filter bag cover 17 during replacement. Each filter bag 6 contains an adsorber 5 coaxial with the filter bag 6 .

[0019] The bottom of the adsorber 5 is clos...

Embodiment 2

[0023] Embodiment 2: as Figure 4 , Figure 5 , Image 6As shown, an integrated dust removal and gaseous pollutant removal device includes a bracket 13 and a bag filter. The bag filter is composed of ash cleaning device, box body 4, ash bin 3 and ash unloading device 1 from top to bottom. Several vertically installed filter bags 6 are arranged in the box body 4 . The filter material of the filter bag 6 is pps fiber. The top of the filter bag 6 is sealed, the upper part passes through the flower plate 11, hangs on the vibrating frame 21, and the lower part is tied on the lower flower plate 12. Each filter bag 6 is provided with an adsorber 5 coaxial with the filter bag 6 . The adsorber 5 surrounds the filter bag 6, which is one-to-one corresponding and coaxial with the filter bag 6. The top and bottom of the adsorber 5 are sealed, and there is a sufficient gap between the adsorber 5 and the filter bag 6 to prevent the filter bag 6 from colliding with the filter bag 6 durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com