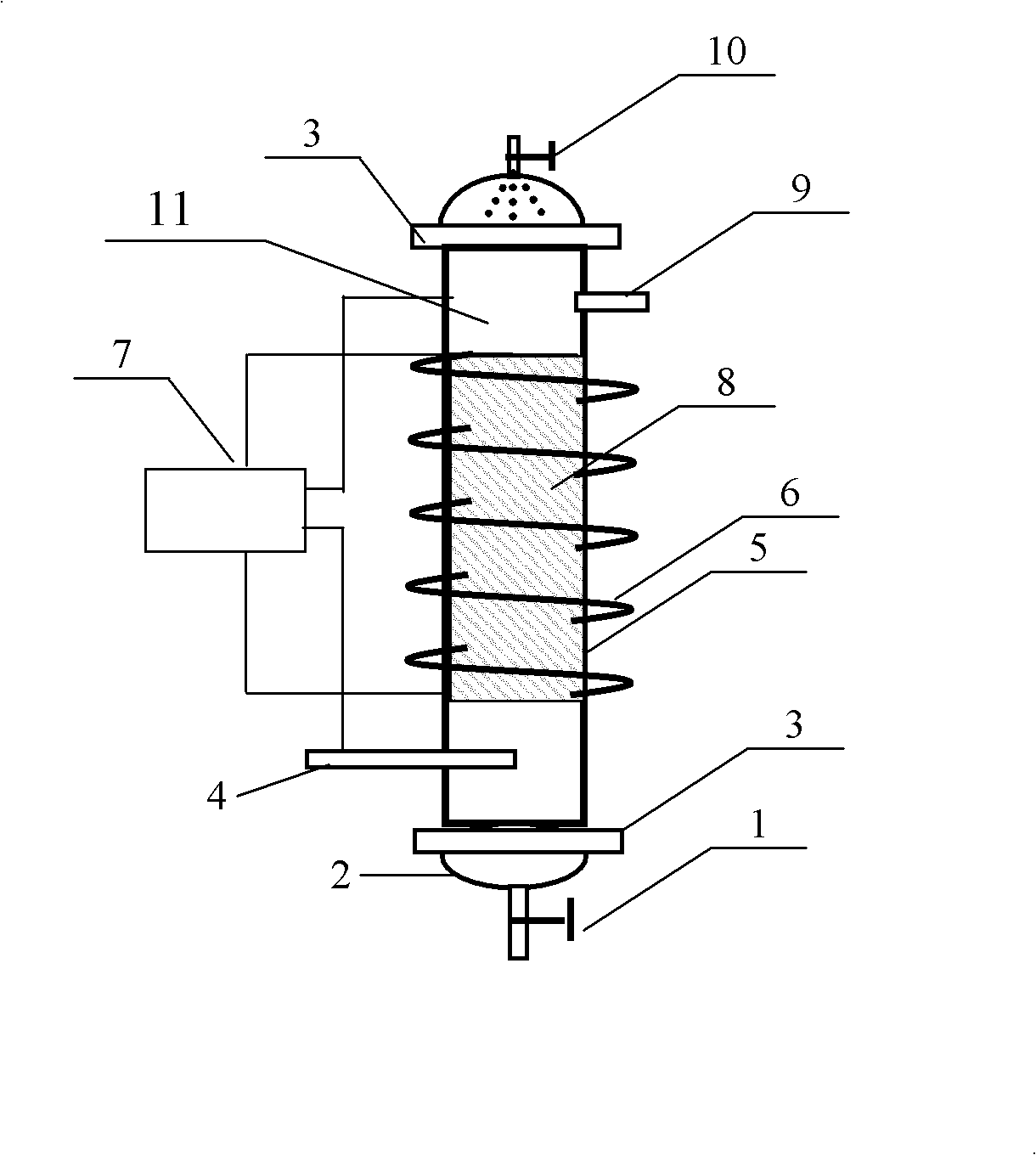

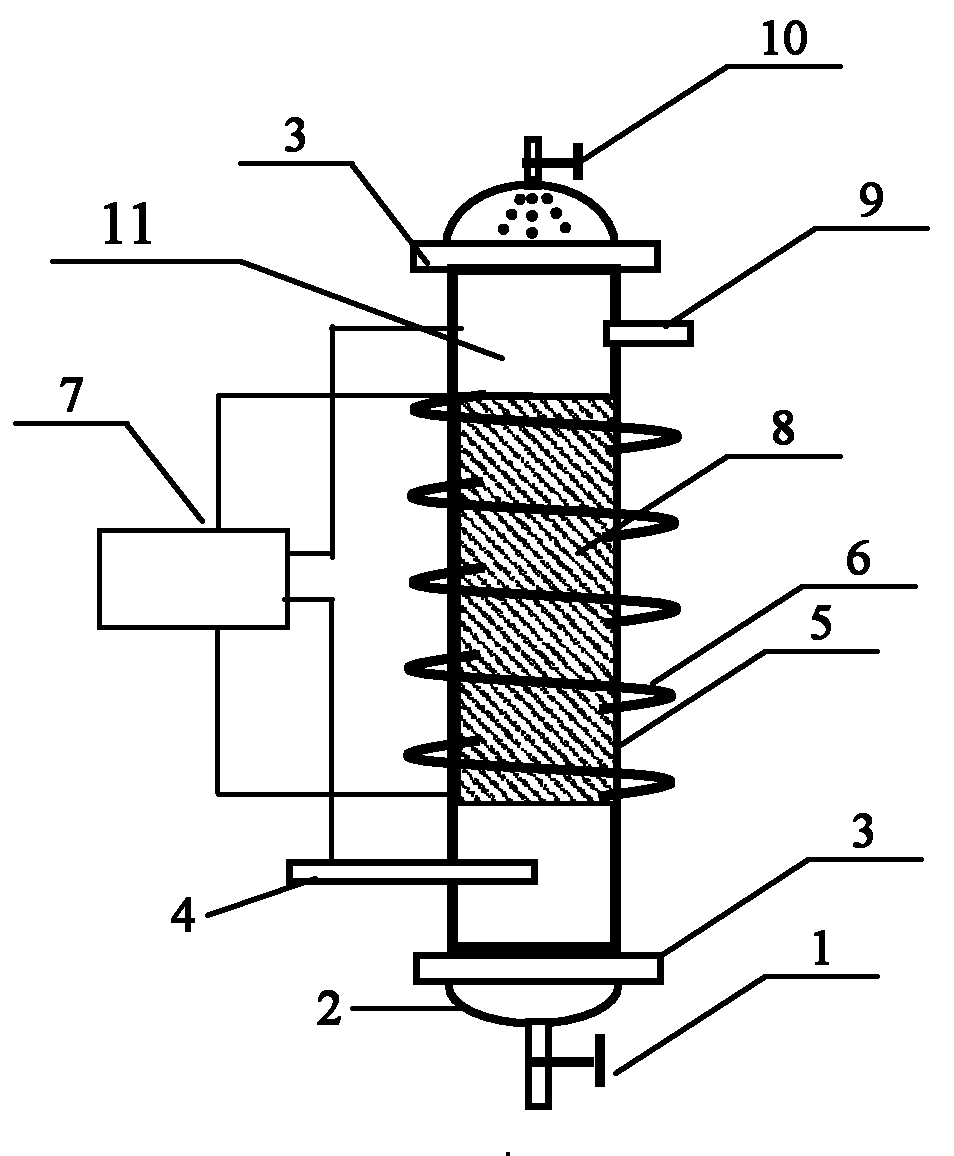

Method and device for controlling clogging of filler layer of biofiltration device

A filter device and biological filtration technology, applied in the field of environmental governance, can solve problems such as plugging of packing layers, achieve the effect of reducing maintenance costs and prolonging stable operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Use an electric heating rod to heat the air to 60°C (relative humidity is 65%), with a gas flow rate of 0.1m 3 / h into a biofiltration device with an effective volume of 3.1L (300-500mg / m has been treated for 70 consecutive days -3 toluene gas), the superficial flow velocity of the gas in the biological filter device is 0.6m / min, and the electric heating belt wound on the outer wall of the biological filter device is used to ensure that the outlet gas temperature is not lower than 55°C. After 30 minutes of high-temperature gas, The pressure drop of the packing layer of the biological filter device is 5mm water column. Under the same conditions, the pressure drop of the packing layer is 20mm water column for the biofiltration device that is fed with normal temperature (35°C) gas.

Embodiment 2

[0027] Use an electric heating rod to heat the air to 60°C (relative humidity is 65%), with a gas flow rate of 0.2m 3 / h into a biofiltration device with an effective volume of 3.1L (300-500mg / m has been treated for 70 consecutive days -3 toluene gas), the superficial flow velocity of the gas in the biological filter device is 1.2m / min, and the electric heating belt wrapped around the outer wall of the biological filter device is used to ensure that the outlet gas temperature is not lower than 58°C. After 30 minutes of high-temperature gas, The pressure drop of the packing layer of the biological filter device is 5mm water column. Under the same conditions, the pressure drop of the packing layer is 20mm water column for the biofiltration device that is fed with normal temperature (35°C) gas.

Embodiment 3

[0029] Use an electric heating rod to heat the air to 65°C (relative humidity is 65%), with a gas flow rate of 0.1m 3 / h into a biofiltration device with an effective volume of 3.1L (300-500mg / m has been treated for 70 consecutive days -3 toluene gas), the superficial flow velocity of the gas in the biological filter device is 0.6m / min, and the electric heating belt wound on the outer wall of the biological filter device is used to ensure that the outlet gas temperature is not lower than 55°C. After 30 minutes of high-temperature gas, The pressure drop of the packing layer of the biological filter device is 6mm water column. Under the same conditions, the pressure drop of the packing layer is 20mm water column for the biofiltration device that is fed with normal temperature (35°C) gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com