Aluminum alloy digital welding machine with smooth transition double-pulse parameters

A smooth transition and double-pulse technology, which is applied in the field of double-pulse aluminum alloy digital welding machine and aluminum alloy digital welding machine, can solve the problems of unstable arc state, fast heat dissipation of aluminum alloy, and unstable arc length, etc., so as to improve welding Efficiency, stable welding, and workload reduction effects

Active Publication Date: 2011-06-15

EAST GRP CO LTD

View PDF5 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, domestic manufacturers are still exploring the dual-pulse welding technology of aluminum alloys, and have not yet made a substantial breakthrough, mainly because the internal regularity has not been found in the design of double-pulse parameters.

The reason is mainly because there are many welding parameters of the double pulse, and a large number of process tests are required for proper matching between them, while the aluminum alloy dissipates heat quickly, and the welding process is extremely unstable; in addition, the arc length is unstable, and the welding wire is easy to burn back. Short circuit, low melting point and easy evaporation of welding wire lead to very unstable arc state

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

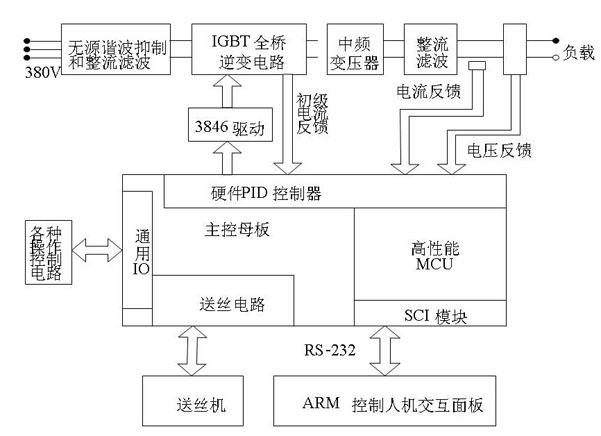

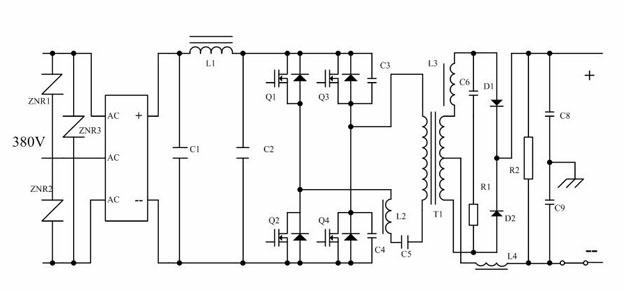

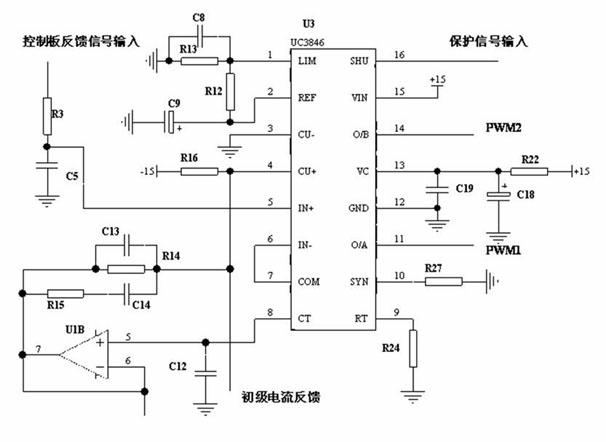

The invention discloses an aluminum alloy digital welding machine with smooth transition double-pulse parameters, which comprises a power main circuit, a main control mother board, a main control micro controller unit (MCU), a wire feed driving circuit, an advanced RISC machine (ARM) controlled human-machine interactive system and a hardware proportion integration differentiation (PID) controller, wherein the hardware PID controller, the wire feed driving circuit and the main control MCU are arranged on the main control mother board; the wire feed driving circuit is connected with the main control MCU; the hardware PID controller is connected with the main control MCU and the control port of the power main circuit; the current input end of the power main circuit is connected with the utility power; and the current output end of the power main circuit is connected with a welding load. The MCU and the ARM are used as control cores, pulse width modulation (PWM) is generated through the hardware PID controller to realize driving control of the main circuit, the work load of the main control MCU is reduced, the main control MCU quickly and stably completes welding process flow control and double-pulse waveform database management task, the welding efficiency is improved, and stable welding of aluminum alloy from low current to high current is realized.

Description

Aluminum Alloy Digital Welding Machine with Smooth Transition Double Pulse Parameters technical field The invention relates to the technical field of double-pulse aluminum alloy digital welding machines, in particular to an aluminum alloy digital welding machine with smooth transition double-pulse parameters. Background technique With the development of power electronics technology and digital technology, high-performance single-chip microcomputers (MCUs) have made epoch-making breakthroughs in terms of functions, processing speed and processing capabilities, and the theory and implementation methods of digital signal processing have achieved unprecedented development. One of the fastest growing disciplines. After the high-end single-chip microcomputer MCU was successfully introduced into the field of welding power source control, it provided the possibility to further improve the performance of the welding process and provided opportunities for trying new welding processe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K9/09B23K9/095

Inventor 薛家祥陈小峰林放徐海波崔龙彬

Owner EAST GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com