Dihydrate desulphurization gypsum rubber reinforcing agent

A technology of rubber reinforcing agent and desulfurization gypsum is applied in the field of rubber additives, which can solve the problems of small utilization and achieve the effects of improved grinding efficiency, easy realization and uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

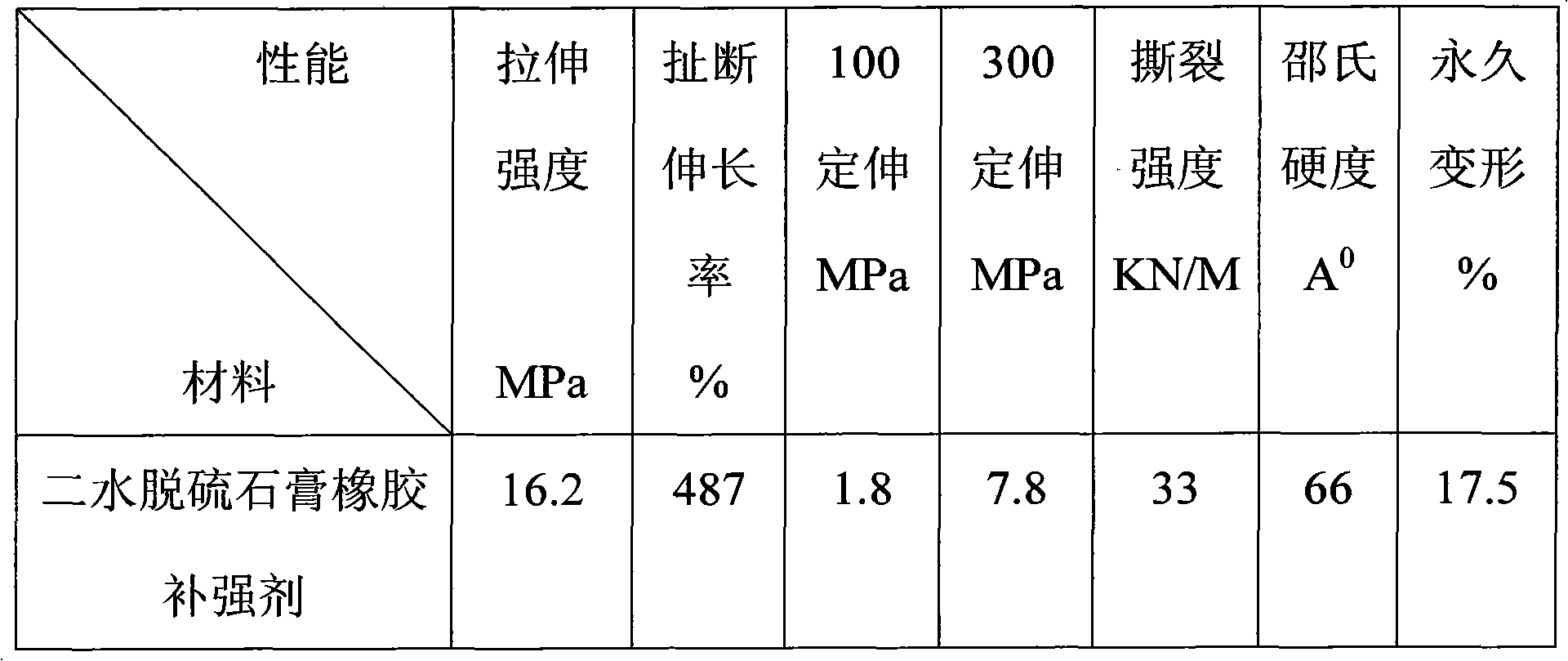

Examples

Embodiment 1

[0023] Embodiment one: (preparation of composite coupling agent)

[0024] formula:

[0025] Silane coupling agent 2Kg Titanate coupling agent 4Kg

[0026] Aluminate coupling agent 4Kg Triethanolamine 2Kg

[0027] Thinner (propylene oxide propylene ether) 48Kg

[0028] Preparation:

[0029] After mixing the silane coupling agent, titanate coupling agent, aluminate coupling agent and triethanolamine in the formulated amount, they are added into propylene oxide propylene ether for dilution and amplification.

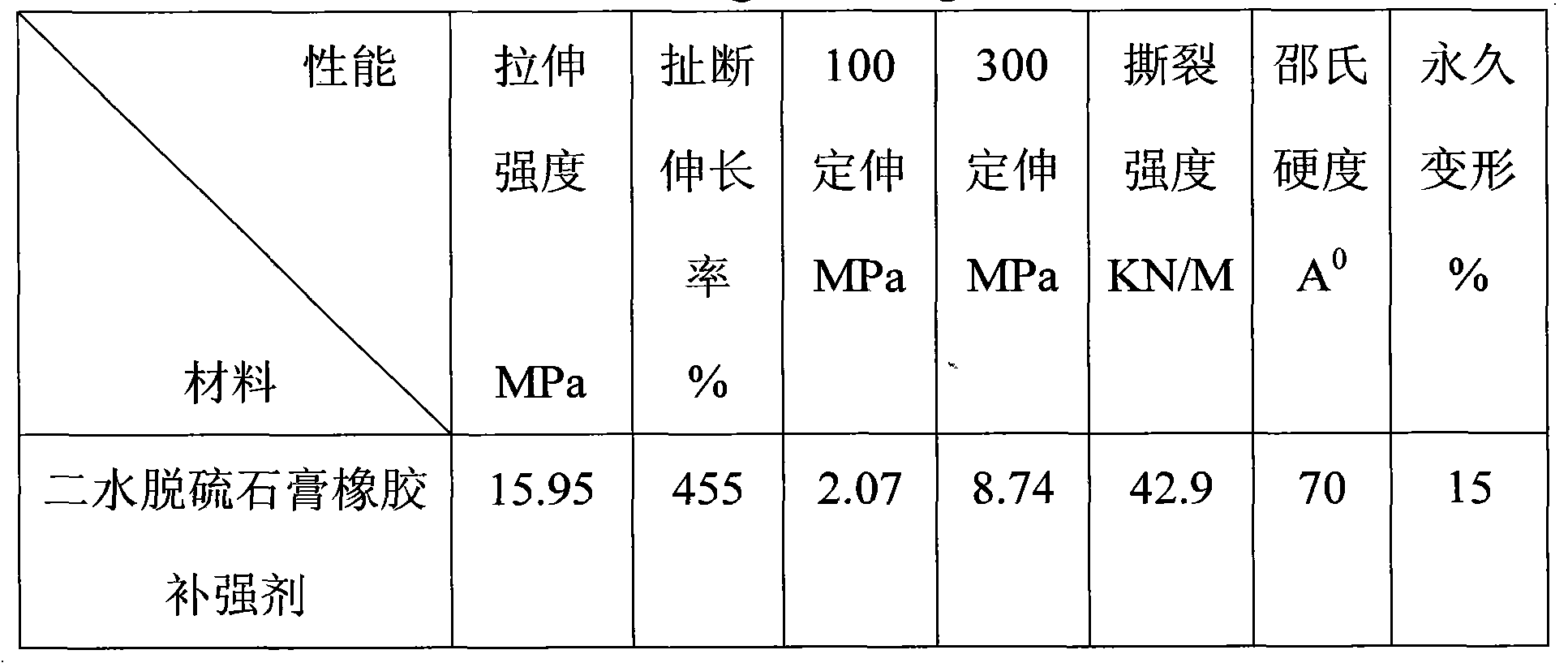

Embodiment 2

[0031] formula:

[0032] Dihydrate desulfurized gypsum 89Kg composite coupling agent 11Kg

[0033] The composite coupling agent is prepared by the method described in Example 1.

[0034] Preparation:

[0035] a. Dry the dihydrate desulfurized gypsum with a dryer until the moisture content is below 1%;

[0036] B, start the mill, add the desulfurized gypsum dihydrate of the recipe amount into the mill (with winnowing function) and grind, while grinding, gradually add the composite coupling agent of the recipe amount, and grind to More than 600 mesh is enough.

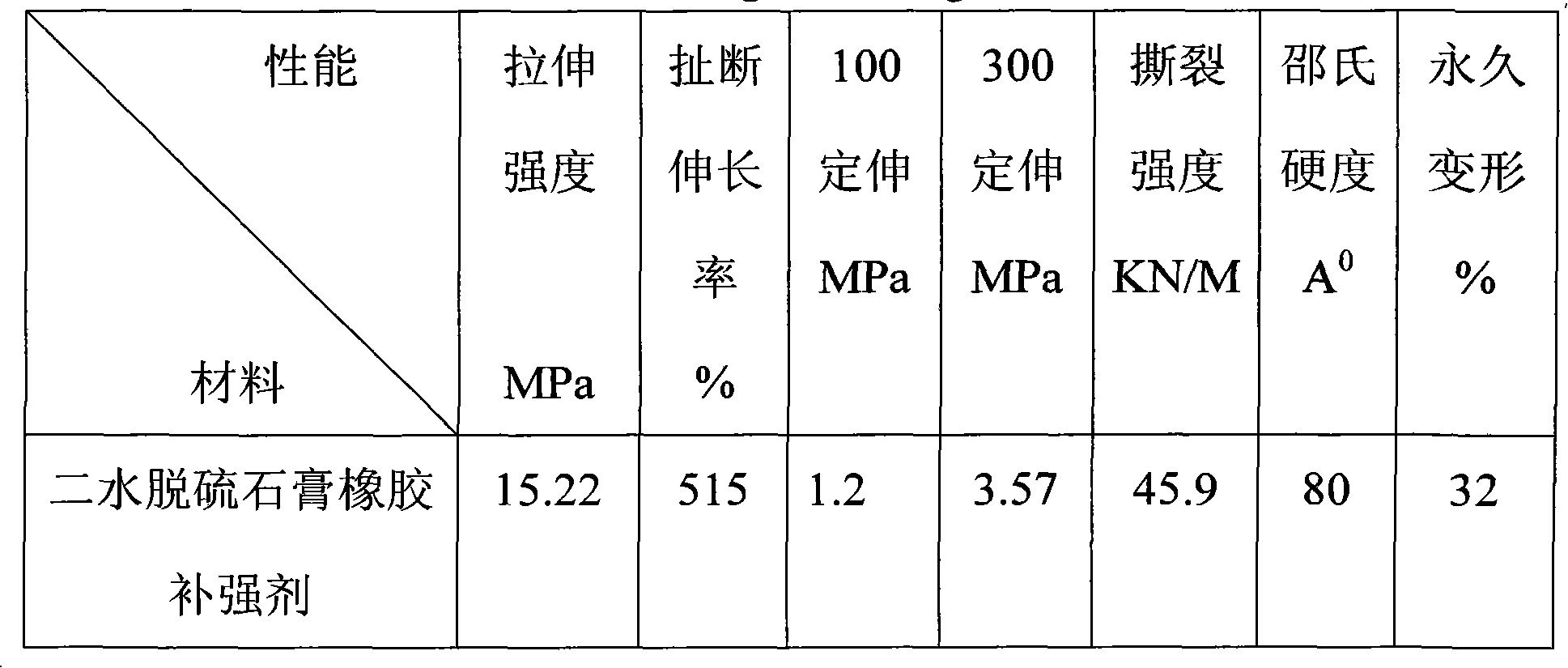

Embodiment 3

[0038] formula:

[0039] Dihydrate desulfurized gypsum 88Kg Composite coupling agent 11.5Kg

[0040] The composite coupling agent is prepared by the method described in Example 1.

[0041] The preparation method is the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com