Water soluble electromagnetic wave shielding transfer printing ink and electromagnetic radiation resistant floor prepared by using same

An anti-electromagnetic radiation and electromagnetic wave technology, applied in the direction of ink, application, printing, etc., can solve the problems of poor anti-electromagnetic radiation effect, and achieve the effect of good anti-electromagnetic radiation and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

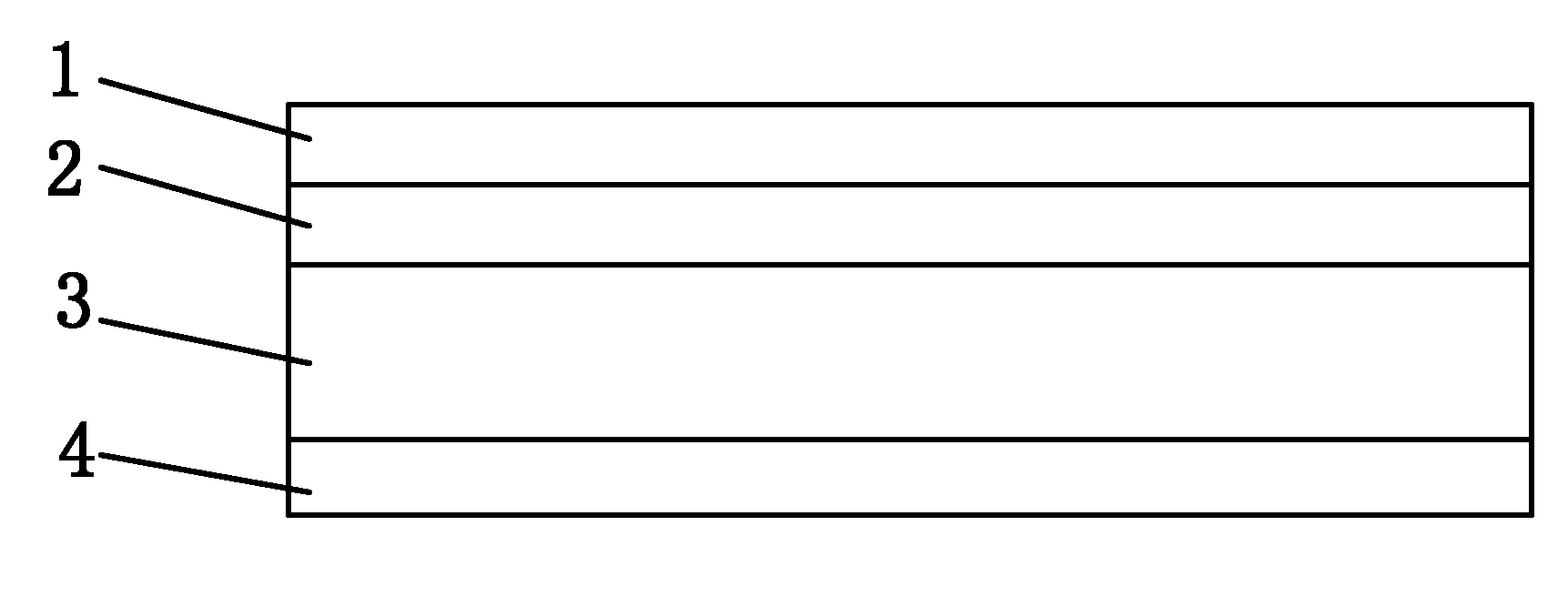

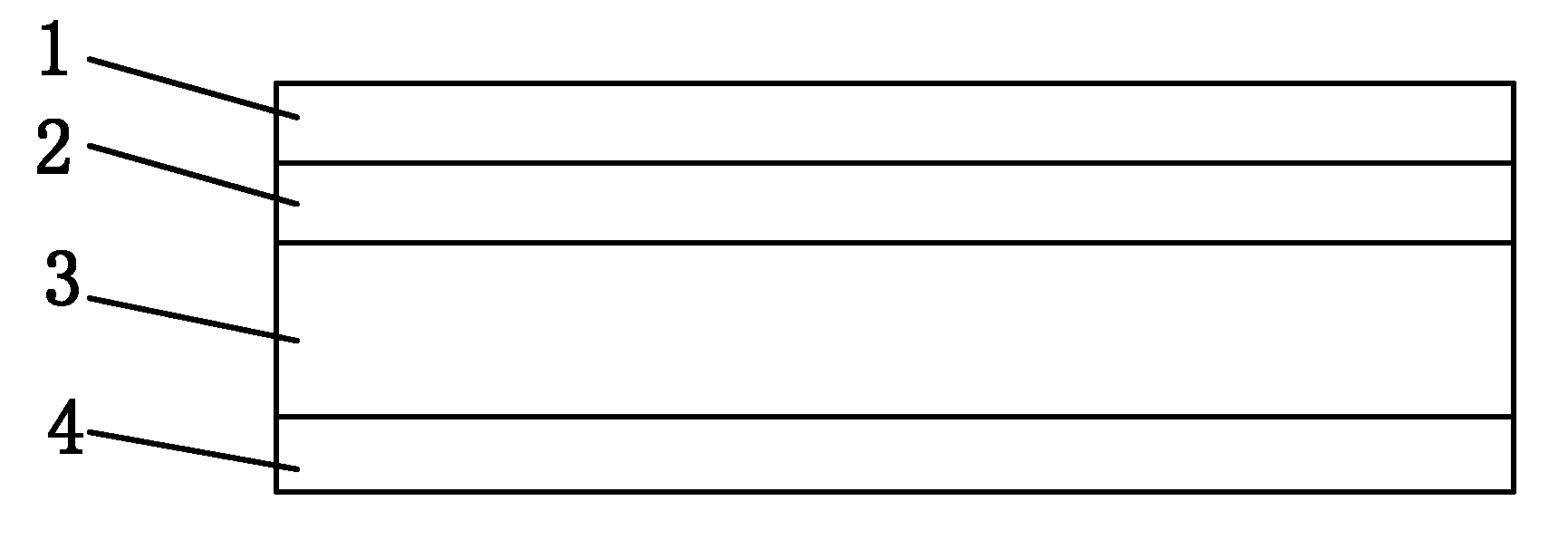

Image

Examples

Embodiment 1

[0061]A water-soluble electromagnetic wave shielding transfer printing ink, which is composed of the following raw materials in parts by mass: 25 parts of styrene-acrylic emulsion, 16 parts of nano-scale barium ferrite (BF) magnetic powder, 29 parts of deionized water, 5 parts of alcohol ester-12 , 15 parts of EVA emulsion, 6 parts of PE water-based wax, 3 parts of water-based leveling agent, and 1 part of water-based defoamer. The styrene-acrylic emulsion of the present embodiment adopts the styrene-acrylic emulsion of HYDRO-REZ 1830 of the U.S. Lauter Company; the EVA emulsion adopts the EVA707 of Guangzhou Qisheng Chemical Trade Co., Ltd.; ; The water-based leveling agent adopts 455 water-based leveling agent of Taiwan Deqian Company; the water-based defoamer adopts 0506 water-based defoamer of Taiwan Deqian Company.

[0062] The preparation method of the water-soluble electromagnetic wave shielding transfer printing ink comprises the following preparation steps:

[0063] ...

Embodiment 2

[0072] A water-soluble electromagnetic wave shielding transfer printing ink, which is composed of the following raw materials in parts by mass: 35 parts of styrene-acrylic emulsion, 15 parts of nano-scale barium ferrite (BF) magnetic powder, 34 parts of deionized water, and 1 part of alcohol ester-12 , 10 parts of EVA emulsion, 3 parts of PE water-based wax, 3 parts of water-based leveling agent, and 1 part of water-based defoamer. The styrene-acrylic emulsion of the present embodiment adopts the styrene-acrylic emulsion of HYDRO-REZ 1830 of the U.S. Lauter Company; the EVA emulsion adopts the EVA707 of Guangzhou Qisheng Chemical Trade Co., Ltd.; ; The water-based leveling agent adopts 455 water-based leveling agent of Taiwan Deqian Company; the water-based defoamer adopts 0506 water-based defoamer of Taiwan Deqian Company.

[0073] The preparation method of the water-soluble electromagnetic wave shielding transfer printing ink comprises the following preparation steps:

[00...

Embodiment 3

[0083] A water-soluble electromagnetic wave shielding transfer printing ink, which is composed of the following raw materials in parts by mass: 30 parts of styrene-acrylic emulsion, 17 parts of nano-scale barium ferrite (BF) magnetic powder, 30 parts of deionized water, and 3 parts of alcohol ester-12 , 12 parts of EVA emulsion, 5 parts of PE water-based wax, 2 parts of water-based leveling agent, and 1 part of water-based defoamer. The styrene-acrylic emulsion of the present embodiment adopts the styrene-acrylic emulsion of HYDRO-REZ 1830 of the U.S. Lauter Company; the EVA emulsion adopts the EVA707 of Guangzhou Qisheng Chemical Trade Co., Ltd.; ; The water-based leveling agent adopts 455 water-based leveling agent of Taiwan Deqian Company; the water-based defoamer adopts 0506 water-based defoamer of Taiwan Deqian Company.

[0084] The preparation method of the water-soluble electromagnetic wave shielding transfer printing ink comprises the following preparation steps:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com