Electromagnetic shielding polystyrene foam

A polystyrene foam, electromagnetic shielding technology, applied in the field of special foam materials, can solve the problems of low electromagnetic shielding efficiency, poor electromagnetic radiation resistance, and high cost, and achieve the effects of good electromagnetic shielding performance, static electricity prevention, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

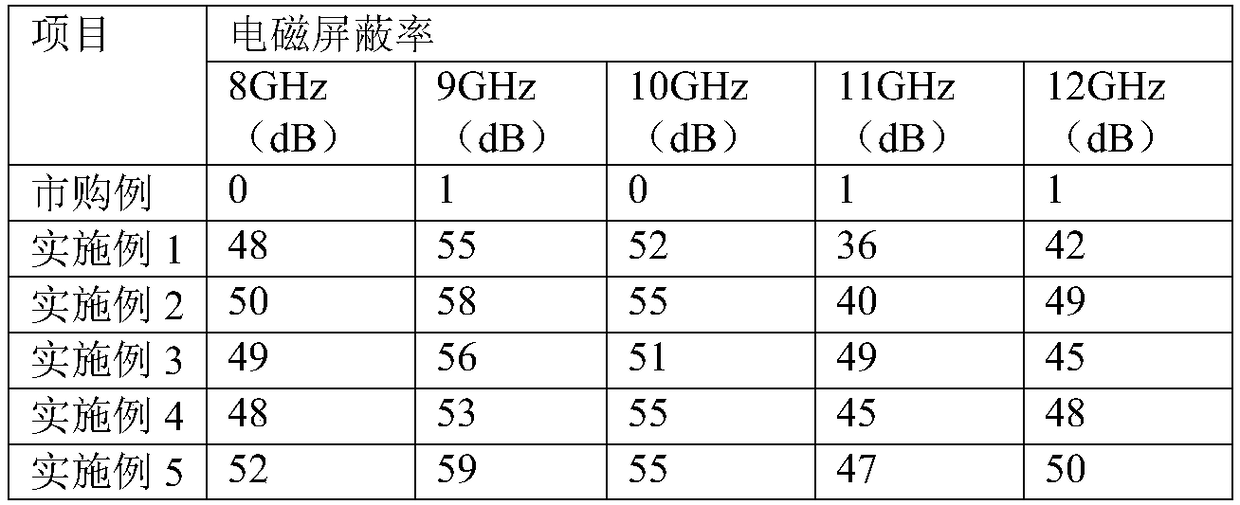

Examples

Embodiment 1

[0024] An electromagnetic shielding polystyrene foam, the foam includes the following components in parts by weight: 100 parts of polystyrene masterbatch, 10 parts of nano-lead tungstate silica gel, 15 parts of powdered graphene microchips, reduced 5 parts of iron powder, 5 parts of silane-modified carboxymethyl starch, 2 parts of n-pentane, 3 parts of melamine, 1 part of ammonium polyphosphate and 0.25 part of dibutyltin dilaurate, wherein the powdered graphene microsheet The thickness is 50-120 nanometers, and the width is 10-20 microns. The reduced iron powder is primary reduced iron powder, and its particle size range is 100-800 μm.

[0025] The preparation method of the nano-lead tungstate silica gel is as follows: weigh 10 parts of methylphenyldimethoxysilane, 30 parts of methyltrimethoxysilane and n-butyl acetate at room temperature according to parts by weight. Put 80 parts in the reaction kettle, stir evenly, add 0.5 parts of hydrochloric acid with a pH of 1 to it and...

Embodiment 2

[0028] An electromagnetic shielding polystyrene foam, the foam includes the following components in parts by weight: 100 parts of polystyrene masterbatch, 25 parts of nano-lead tungstate silicon gel, 25 parts of powdered graphene microchips, reduced 15 parts of iron powder, 15 parts of silane-modified carboxymethyl starch, 10 parts of n-pentane, 10 parts of melamine, 10 parts of ammonium polyphosphate and 0.85 part of dibutyltin dilaurate, wherein the powdered graphene microsheet The thickness is 50-120 nanometers, and the width is 10-20 microns. The reduced iron powder is primary reduced iron powder, and its particle size range is 100-800 μm.

[0029] The preparation method of the nano-lead tungstate silica gel is as follows: weigh 10 parts of methylphenyldimethoxysilane, 45 parts of methyltrimethoxysilane and n-butyl acetate at room temperature according to parts by weight. 100 parts are placed in the reaction kettle, after stirring evenly, add 3 parts of hydrochloric acid w...

Embodiment 3

[0032]An electromagnetic shielding polystyrene foam, said foam comprises the following components in parts by weight: 100 parts of polystyrene masterbatch, 15 parts of nano-lead tungstate silica gel, 15 parts of powdered graphene microchips, reduced 5 parts of iron powder, 10 parts of silane-modified carboxymethyl starch, 5 parts of n-pentane, 3 parts of melamine, 5 parts of ammonium polyphosphate and 0.45 part of dibutyltin dilaurate, wherein the powdered graphene microsheet The thickness is 50-120 nanometers, and the width is 10-20 microns. The reduced iron powder is primary reduced iron powder, and its particle size range is 100-800 μm.

[0033] The preparation method of the nano-lead tungstate silica gel is as follows: weigh 10 parts of methylphenyldimethoxysilane, 35 parts of methyltrimethoxysilane and n-butyl acetate at room temperature according to parts by weight. 85 parts are placed in the reaction kettle, after stirring evenly, add 2 parts of hydrochloric acid with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com