Process for constructing joints between bottom of window on outer wall and inside as well as outside of windowsill

A construction process and joint technology, which is applied to the construction of the inner and outer details of the window sill roof, can solve the problems of affecting the construction speed, affecting the appearance, and easy cracking of the plastering mortar, so as to reduce the possibility of inward water seepage, improve the construction efficiency, The effect of increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

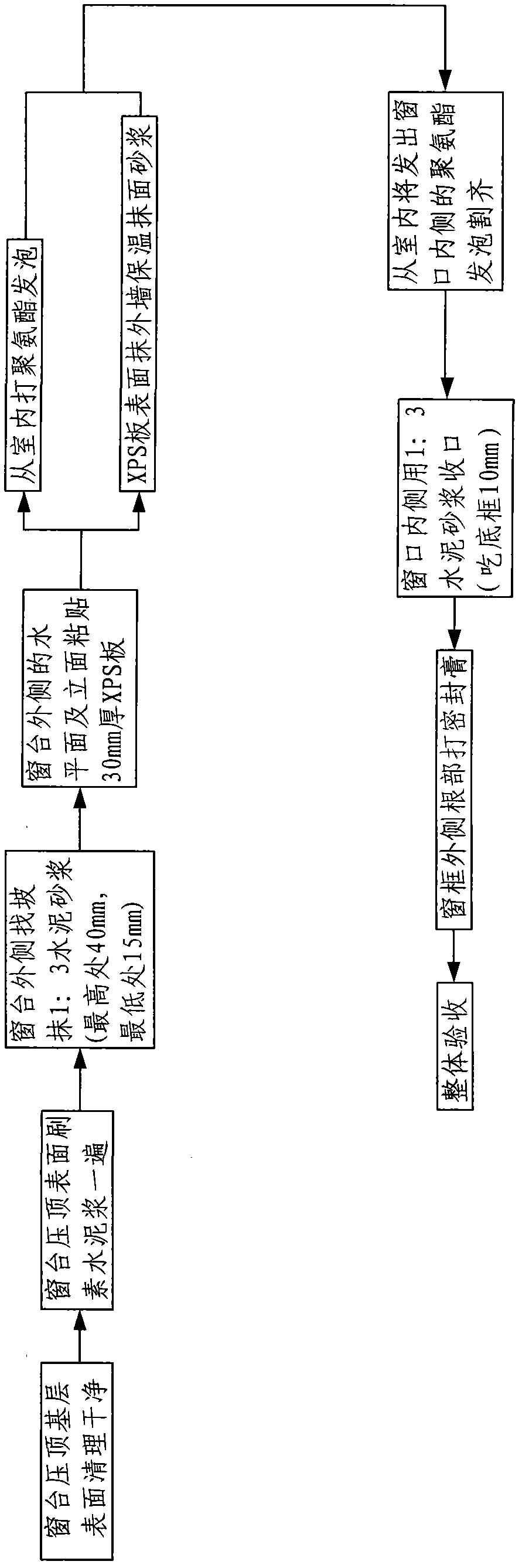

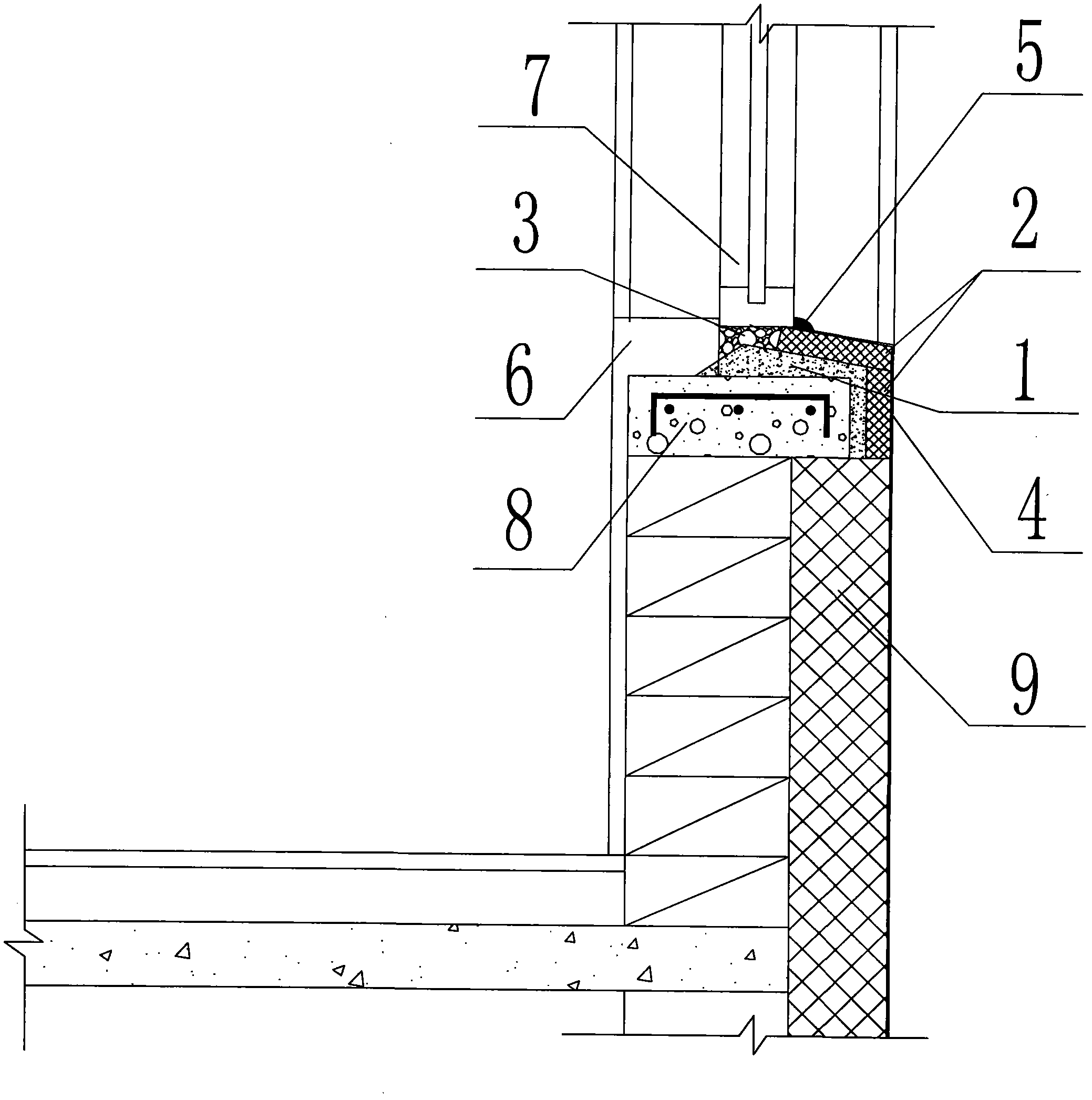

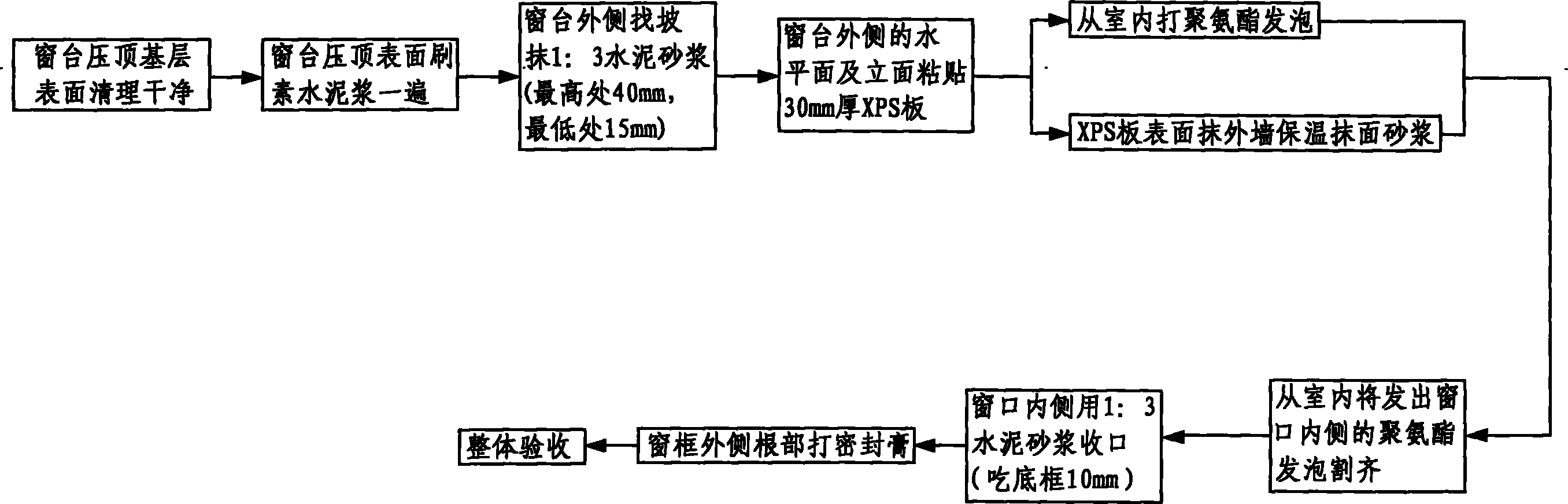

[0022] The following combination figure 1 And the detailed diagram of each main construction step node divided by the construction sequence describes the present invention in detail.

[0023] 1. Before constructing the 1:3 cement mortar slope-seeking plastering layer 1 on the outside of the window sill, the surface of the concrete window sill top 8 must be cleaned, and before plastering, the concrete window sill top 8 should be fully brushed with plain cement slurry once, as The "interface agent" between the plastering layer and the concrete base layer, so that the two can be better combined, and avoid the common problems of hollowing and cracking.

[0024] 2. In the 1:3 cement mortar slope finding and plastering layer 1 project outside the construction window sill, the most important thing is to control the slope and the location of the highest slope, that is, the highest slope is 40mm, the lowest is 15mm, and the highest slope is It should be left at one-third of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com