Device for repairing deformed sleeves by explosion

A technology of casing and explosives, applied in blasting, wellbore/well parts, earthwork drilling and mining, etc., can solve problems such as high operating costs, stuck tools, window opening, etc., and overcome long construction period, short period, construction low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

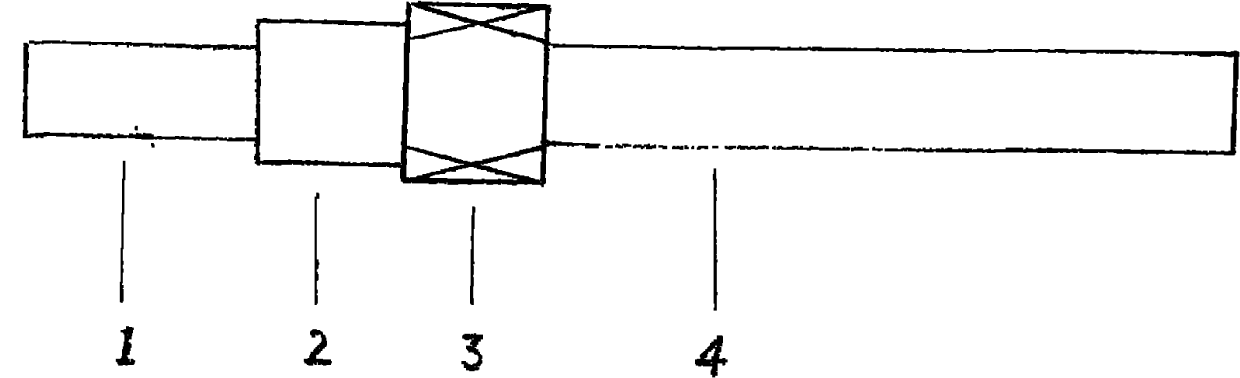

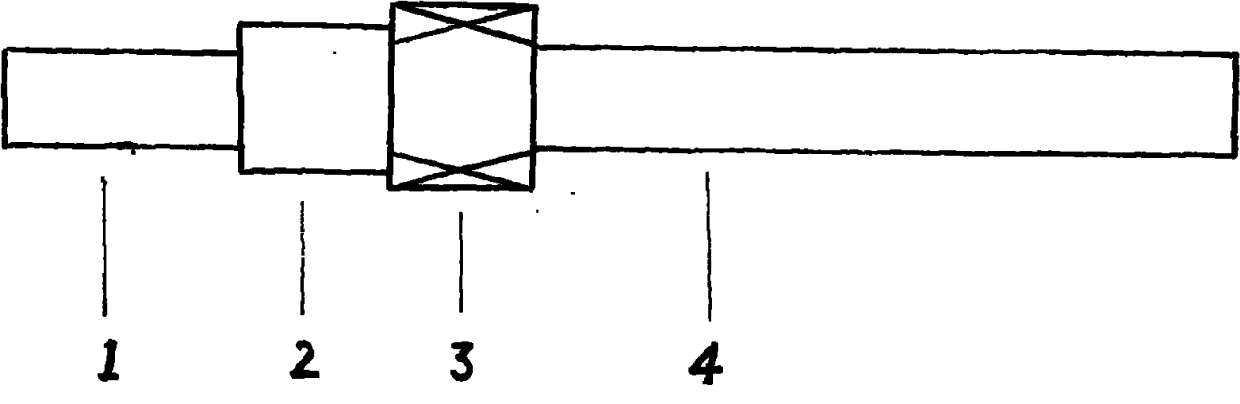

[0022] The present invention will be further described in conjunction with accompanying drawings.

[0023] Drill the well to the deformed place and wash the well; print to verify the deformation of the deformed place; set up the device structure according to the casing deformation and process requirements, and connect it to the well according to the process design requirements; determine the position of the projectile to go into the well and detonate; If it passes smoothly, the construction is completed; in case of obstruction, check the position and prepare for the second construction until the well is deformed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com