Preparation method of bacon

A technology of bacon and chilled fresh meat, applied in the field of food processing, can solve the problems of unfavorable industrial production, hard texture, low efficiency, etc., and achieve the effect of shortening the production cycle, shortening the curing time, and increasing the nutritional content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of bacon, comprises the following steps:

[0025] Trimming the cold fresh meat at 0°C to 4°C into strips to obtain strip-shaped raw meat, the thickness of fat on the strip-shaped raw meat is not more than 1.5cm;

[0026] marinating the strip-shaped raw meat with a marinade for 40h to 60h to obtain marinated meat, the marinade including salt, pepper and five-spice powder;

[0027] Washing and drying the cured meat, and then baking for 6 hours to 10 hours to obtain roasted meat;

[0028] The roasted meat is smoked for 4h to 5h to remove impurities to obtain bacon.

[0029] The invention uses chilled fresh meat at 0°C to 4°C as raw materials to prepare cured meat. Compared with frozen meat, the chilled fresh meat has better color and taste, is easy to pickle, and can effectively shorten the pickling time.

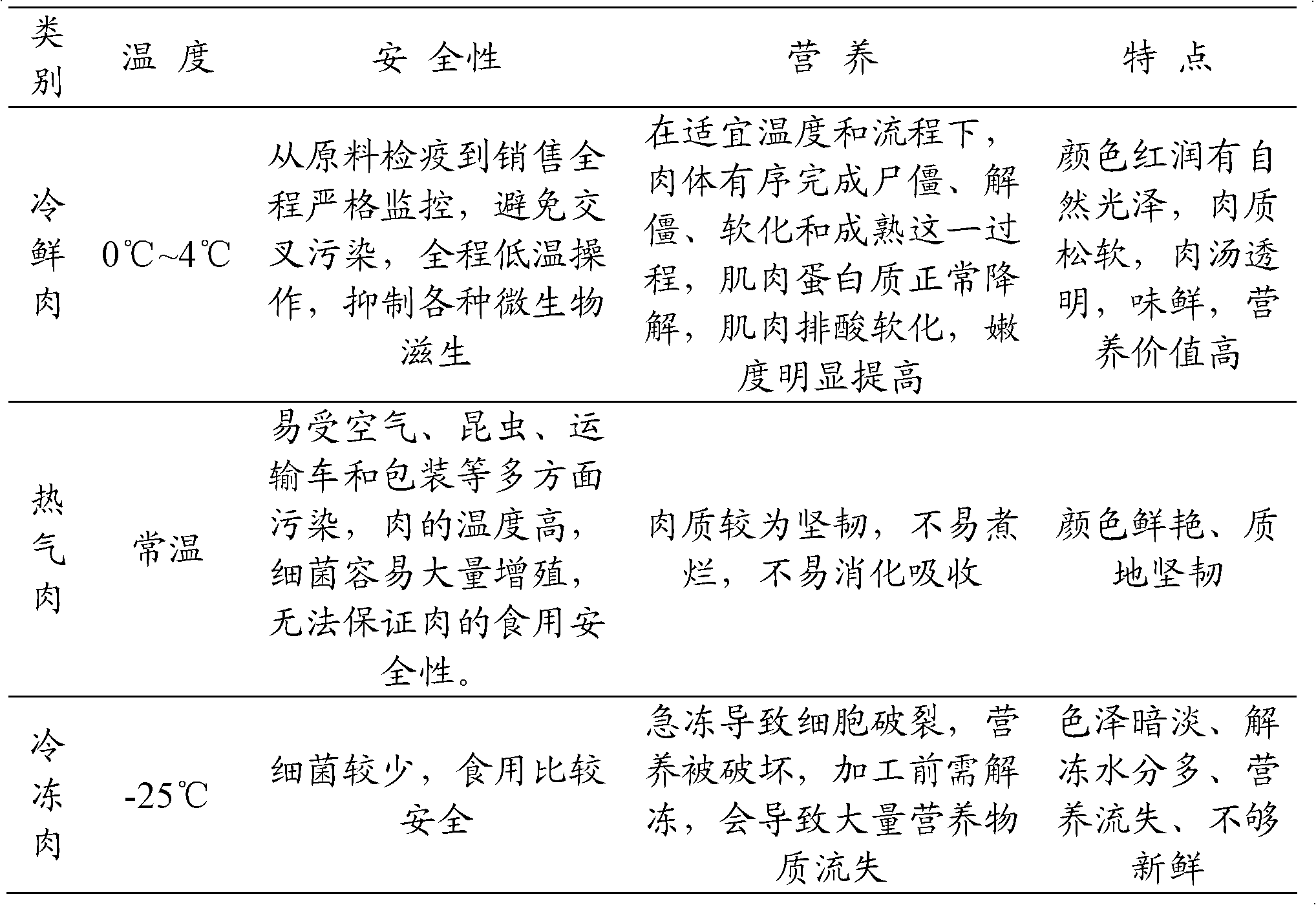

[0030] In this technical field, bacon is generally prepared from cold fresh meat, hot-air meat or frozen meat. Amo...

Embodiment 1

[0050] Trim the cold fresh meat at 0°C into 2cm-3cm strips of raw meat, and make the thickness of the fat on the strips of raw meat not exceed 1.5cm; fry 3kg of salt, 0.02kg of pepper and 0.02kg of five-spice powder Make salt and pepper, sprinkle the salt and pepper on 100kg strips of meat evenly, and spread evenly; put the meat coated with marinade into the bucket, and marinate at 4°C for 48 hours, and turn the meat for 2 hours during the marinating process. times; the cured meat obtained was cleaned in 40°C clear water, and after the blood stains and the marinade were cleaned, it was washed once in ice water and dried in the air until no moisture dripped out, then the meat was baked, Bacon is baked at a constant temperature of 60°C for 8 hours, then transferred to a smoke room at 40°C, smoked with sawn wood for 4 hours, and the soot and grease on the surface of the meat are removed to obtain bacon.

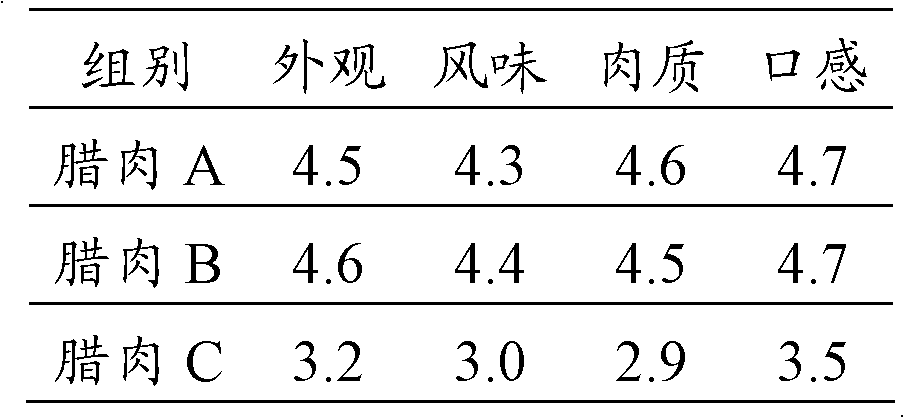

[0051] The obtained bacon is golden in color, alternately fat and thin, ric...

Embodiment 2

[0053] Trim and cut the cold fresh meat at 4°C into 4cm-5cm strip-shaped raw meat, and make the thickness of the fat on the strip-shaped raw meat not exceed 1.5cm; fry 3kg of salt, 0.02kg of pepper and 0.02kg of five-spice powder Make salt and pepper, sprinkle the salt and pepper evenly on 100kg strips of meat, and spread evenly; put the meat coated with marinade into the bucket, and marinate at 7°C for 50 hours, and turn the meat for 2 hours during the marinating process. times; the cured meat obtained was washed in clear water at 50°C, and after blood stains and marinade were cleaned, it was washed once in ice water and dried in the air until no moisture dripped out, then the meat was baked, Bacon is baked at a constant temperature of 60°C for 8 hours, then transferred to a smoke room at 40°C, smoked with sawn wood for 5 hours, and the soot and grease on the surface of the meat are removed to obtain bacon.

[0054] The obtained bacon is golden in color, alternately fat and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com