Drying container

A drying container and container technology, applied in the field of containers, can solve the inevitable result of the finished product being non-true round, unilaterally raised in the direction of less force, even burst open, and different force, etc., to achieve high low pressure resistance , Long validity period and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] This case will be fully understood by the following examples, so that those skilled in the art can complete it, but the implementation of this case can not be limited by the following examples of implementation; that is, the scope of the present invention does not Restricted by the proposed embodiments, the scope of the patent application for the present invention shall prevail.

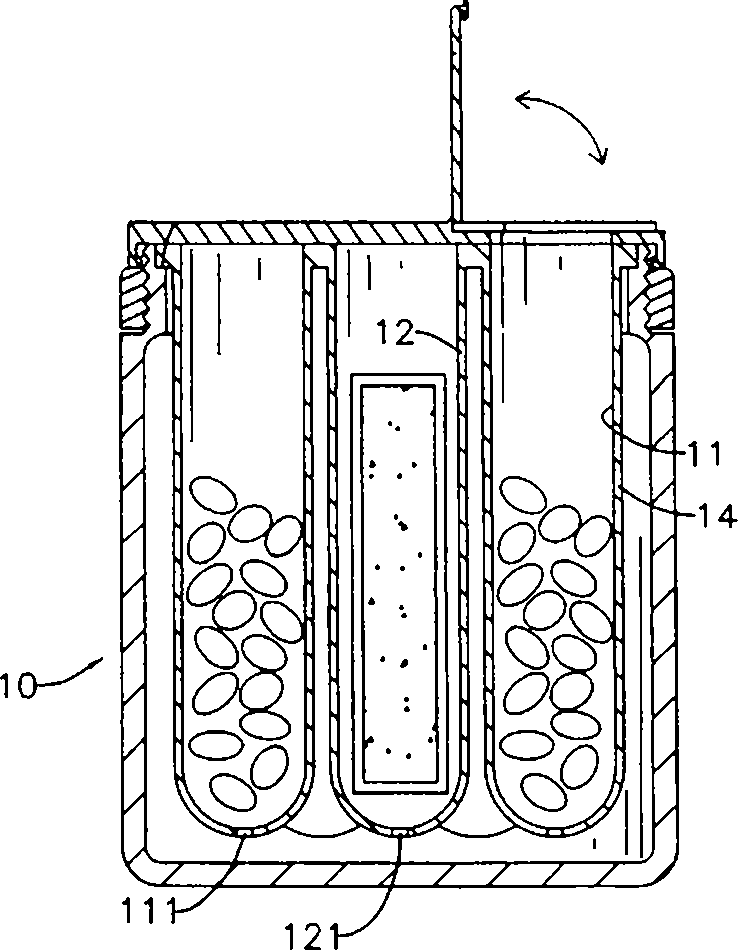

[0044] see image 3 , which is a perspective view of the structure of the drying container of the present invention; the drying container 300 disclosed in the figure mainly includes a main body (also called an outer tank or an outer bottle) 301 and a lining (also called an inner tank or an inner tank) bottle) 302; the inner space 303 of the dry container 300 can preferably be used to store items such as test strips, test papers, medicines, etc., and the inner liner 302 is installed inside the body 301. Preferably, the height of the inner liner 302 will usually be It is smaller than the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com