Technology for preparing high-purity nitrogen trifluoride by removing impurities contained in nitrogen trifluoride through rectification method

A nitrogen trifluoride, rectification technology, applied in the direction of nitrogen and non-metallic compounds, can solve problems such as environmental pollution, and achieve the effect of convenient use and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

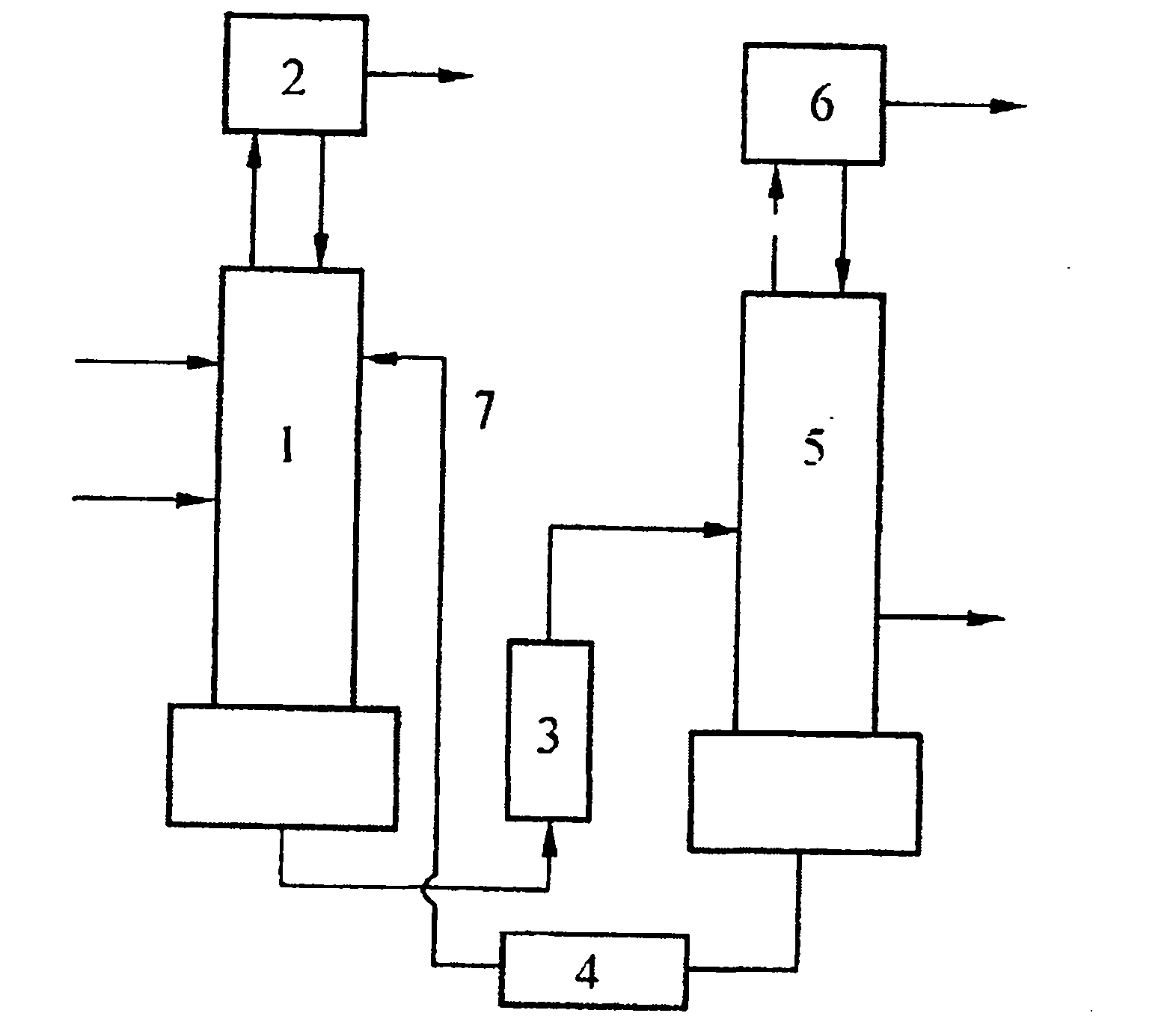

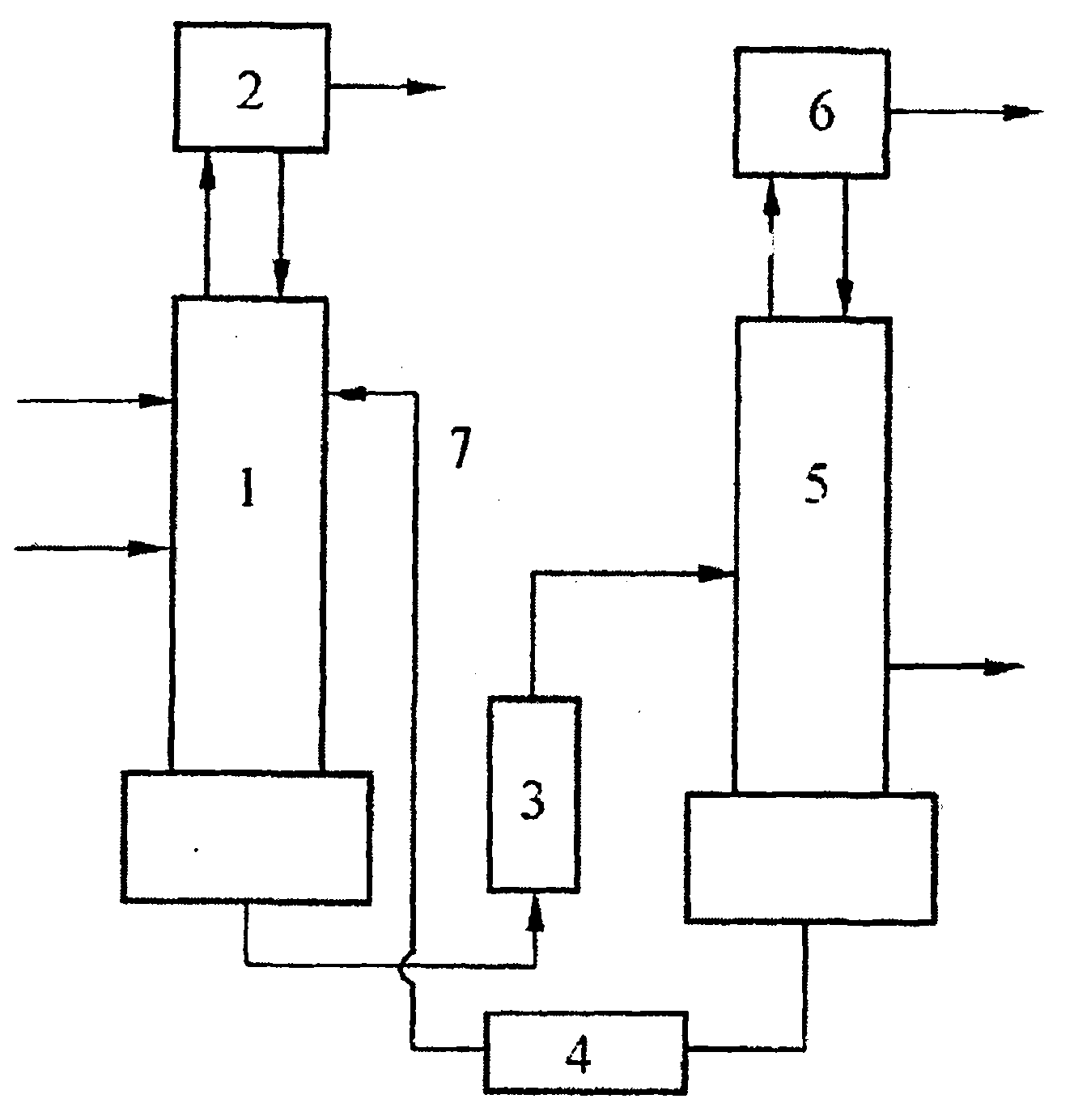

[0011] refer to figure 1 ,1 # Distillation tower 1, 1 # Distillation column condenser 2, 1 # Rectification column bottom liquid vaporizer 3, 2 # Rectification column bottom liquid vaporizer 4, 2 # Distillation tower 5, 2 # The rectifying column condenser 6 is assembled into one body through the connecting pipeline 7 according to its system function.

[0012] Use chemical reaction production process of the present invention:

[0013] Nitrogen trifluoride mixture containing impurities such as difluorohydrazine, tetrafluorohydrazine and carbon tetrafluoride enters 1 # The rectifying tower 1 carries out extraction and rectification, and under normal conditions, the extractant with a boiling point higher than that of nitrogen trifluoride is as HCFC-22, HFC-41, PFC-116, HFC-23, N 2 O.CO 2 etc. The boiling point range of the extractant is generally -90--20°C. pass 1 # Rectification tower 1 makes carbon tetrafluoride and nitrogen trifluoride, difluorohydrazine, tetrafluorohy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com