Flexible composite connection pipe fitting for large-aperture plastic pipeline

A composite connection, plastic pipe technology, applied in the direction of pipe connection layout, pipe/pipe joint/pipe fittings, mechanical equipment, etc., can solve the problems of inconvenient operation, large number of bolts, insecure sealing performance, etc., to achieve simple and easy installation and operation. performance, corrosion-resistant service life, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

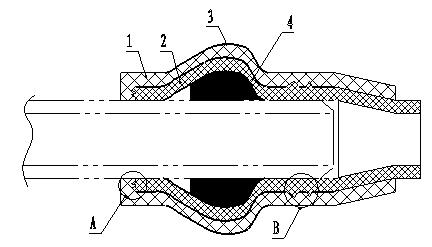

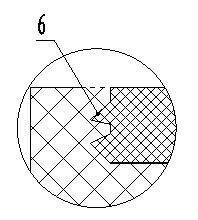

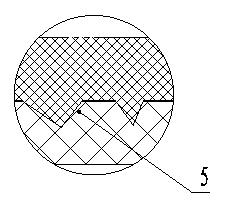

[0016] see figure 1 , the main structure of the present invention includes a PE inner layer pipe section 2 and a PVC outer layer pipe section 1 wrapped on the surface of the PE inner layer pipe section. Based on the material properties of PE and PVC, electrofusion, hot melt or injection molding are used to fuse the two together and form a flare. The flexible nature of PE pipe requires lining support when connecting large-diameter pipe networks, while PVC has the characteristics of high strength. The present invention combines the above two performance advantages to form a flexible composite connection pipe fitting with a special structure. An annular groove 3 is provided on the side where the flexible composite connecting pipe is formed with a flare, and a sealing ring 4 is arranged in the annular groove. The sealing ring 4 can form a radial seal and an axial seal between the PVC pipe and the flexible composite connecting pipe at the same time, and the sealing performance is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com