Exhaust gas purification system for diesel engines of commercial vehicles

A technology for diesel engine and exhaust purification, applied in engine components, combustion engines, machines/engines, etc., and can solve problems such as space problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

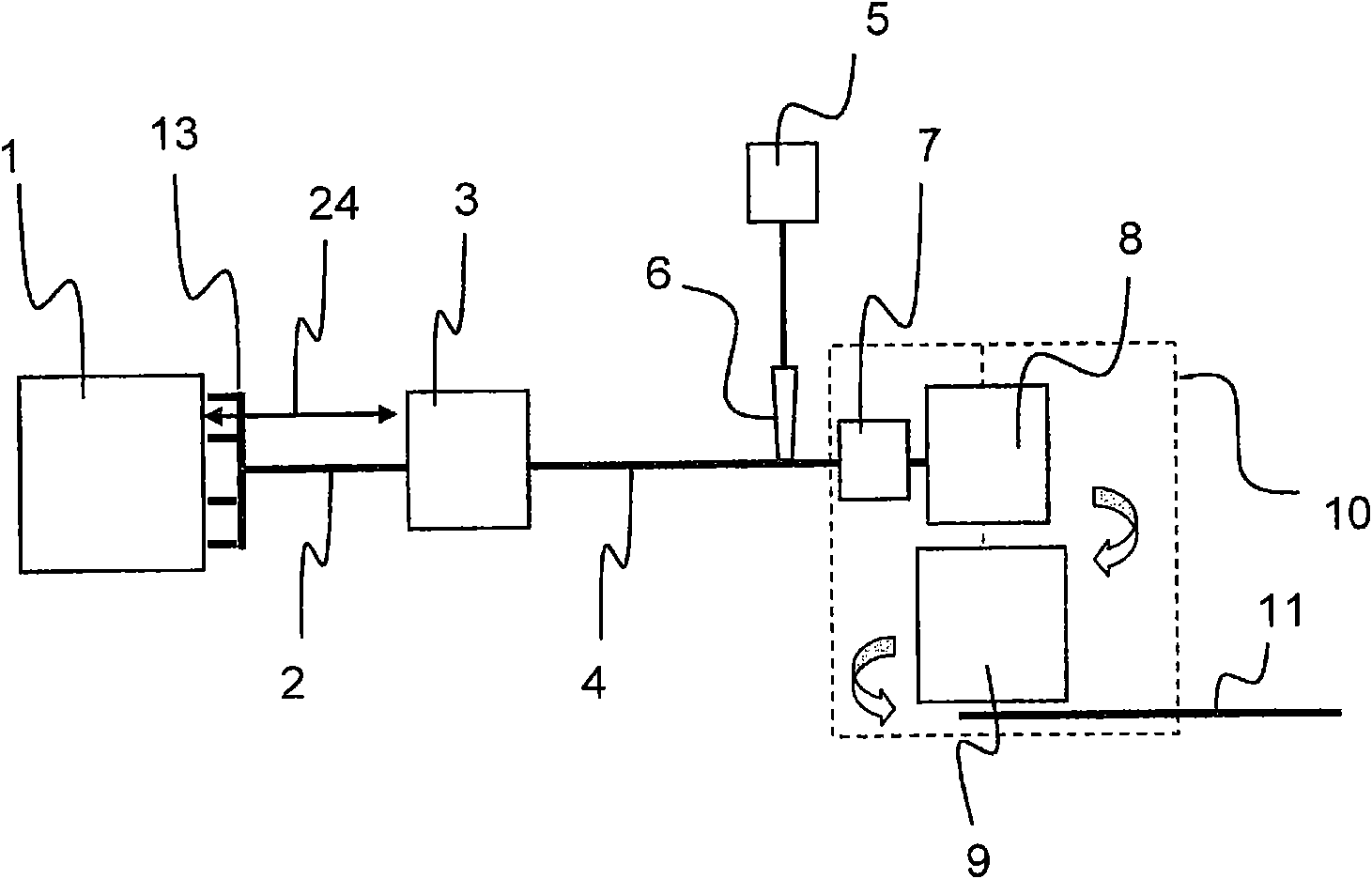

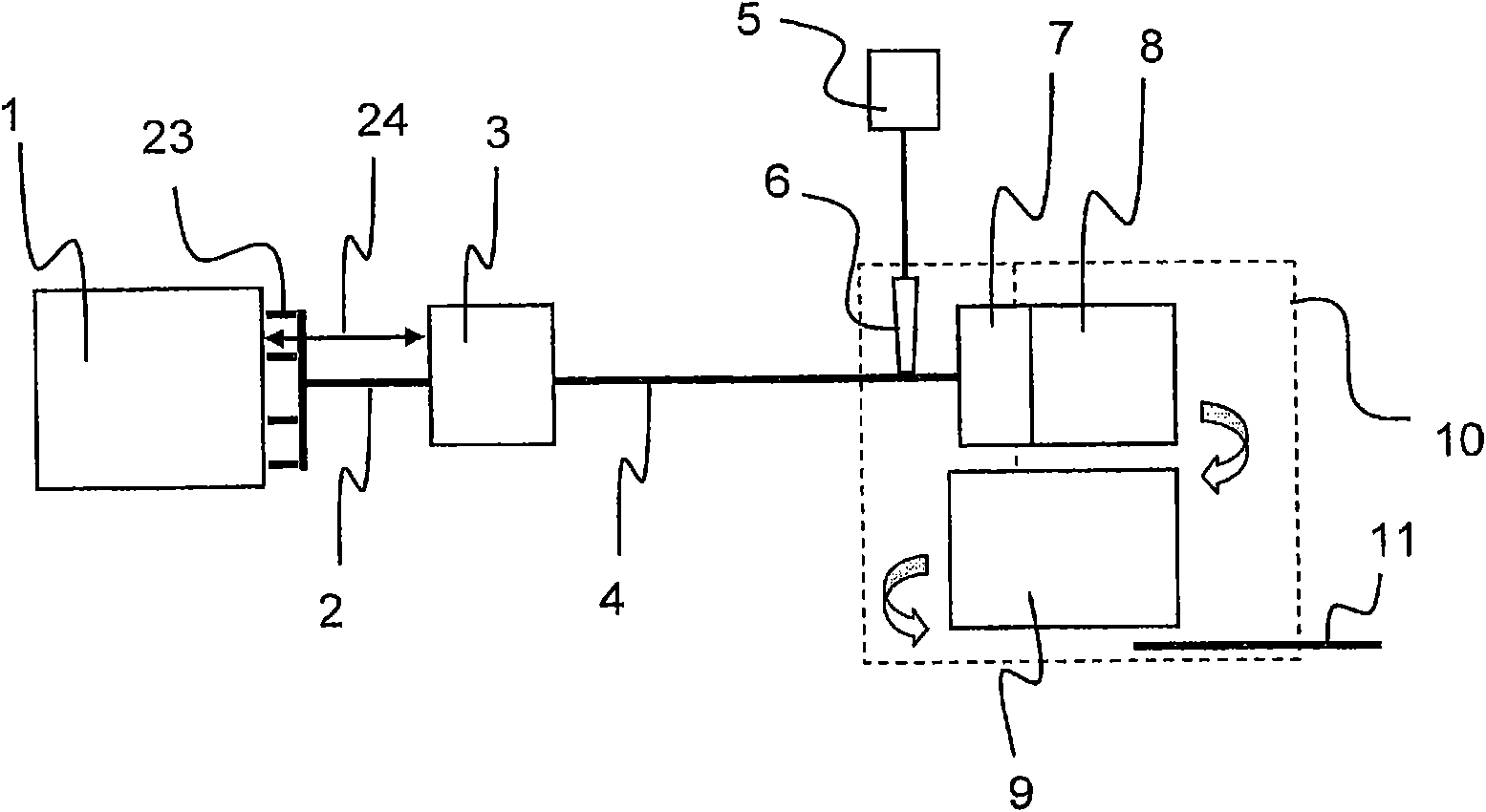

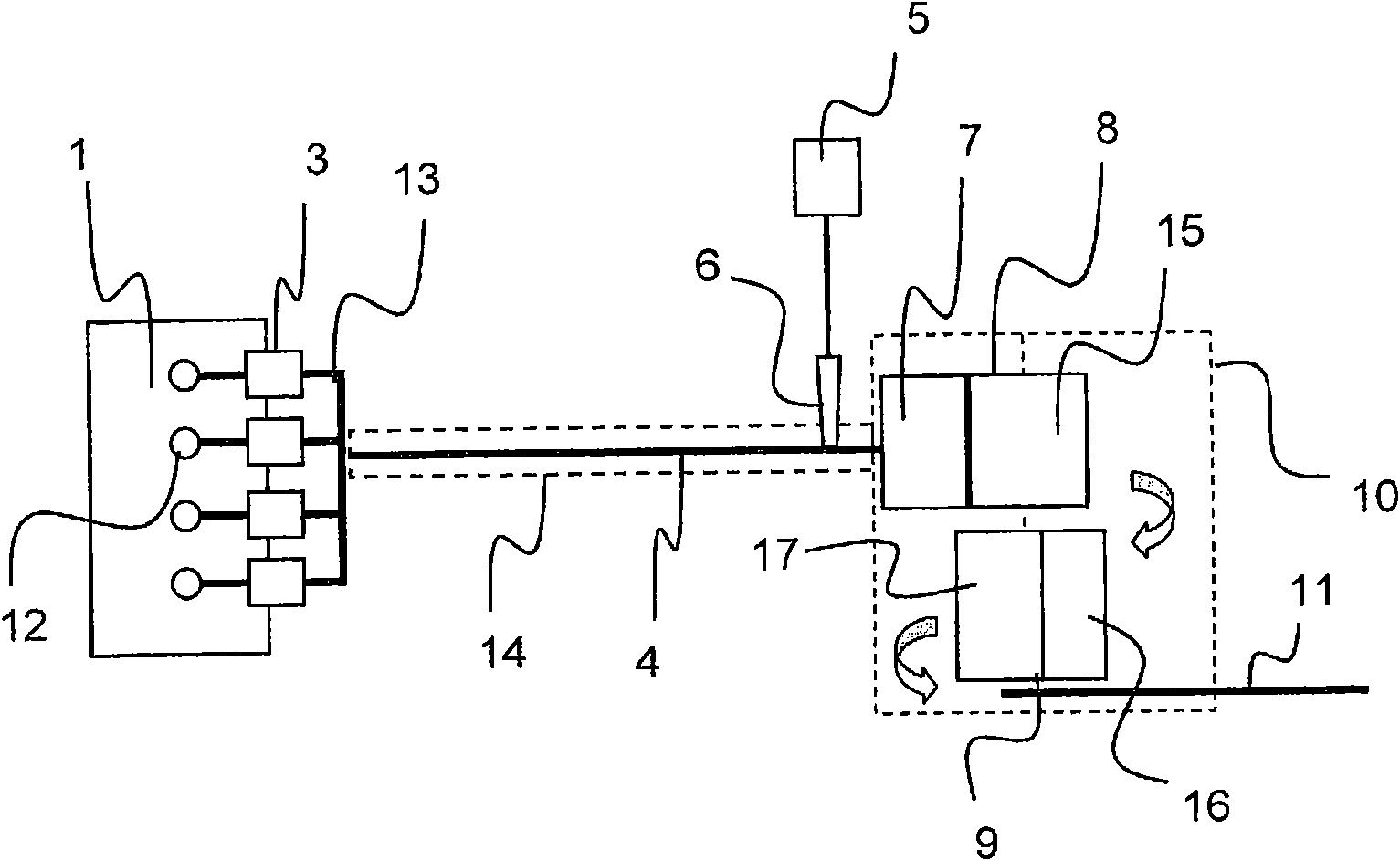

[0035] according to Figure 1-3 The exhaust gas purification system in is used in diesel engines of commercial vehicles, especially for heavy goods vehicles, buses, or ships or aircraft. The power requirements of a commercial vehicle of this size are very high, while at the same time the consumption should be as low as possible. Consequently, the displacement / working volume of such diesel engines for commercial vehicles varies in the range of eg 6 liters to 12 liters or even higher. Such diesel engines are generally equipped with an exhaust-gas turbocharger to increase power and reduce specific consumption. An exhaust-gas turbocharger is understood to be a combination of an exhaust-gas turbine and a turbocompressor, wherein the exhaust-gas turbine is acted upon by the exhaust gas of the diesel engine and the turbocompressor is driven by the exhaust-gas turbine. The intake air to the diesel engine is subjected to an elevated boost pressure by the turbo compressor whereby a gr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap