Method for processing sea intestine powder

A processing method and technology of sea sausage powder, applied in the application, food preparation, food science and other directions, can solve the problems of poor sanitation environment, unable to achieve seasoning, not meeting edible standards, etc., to ensure the hygienic environment, improve the shelf life, Effects without quality risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

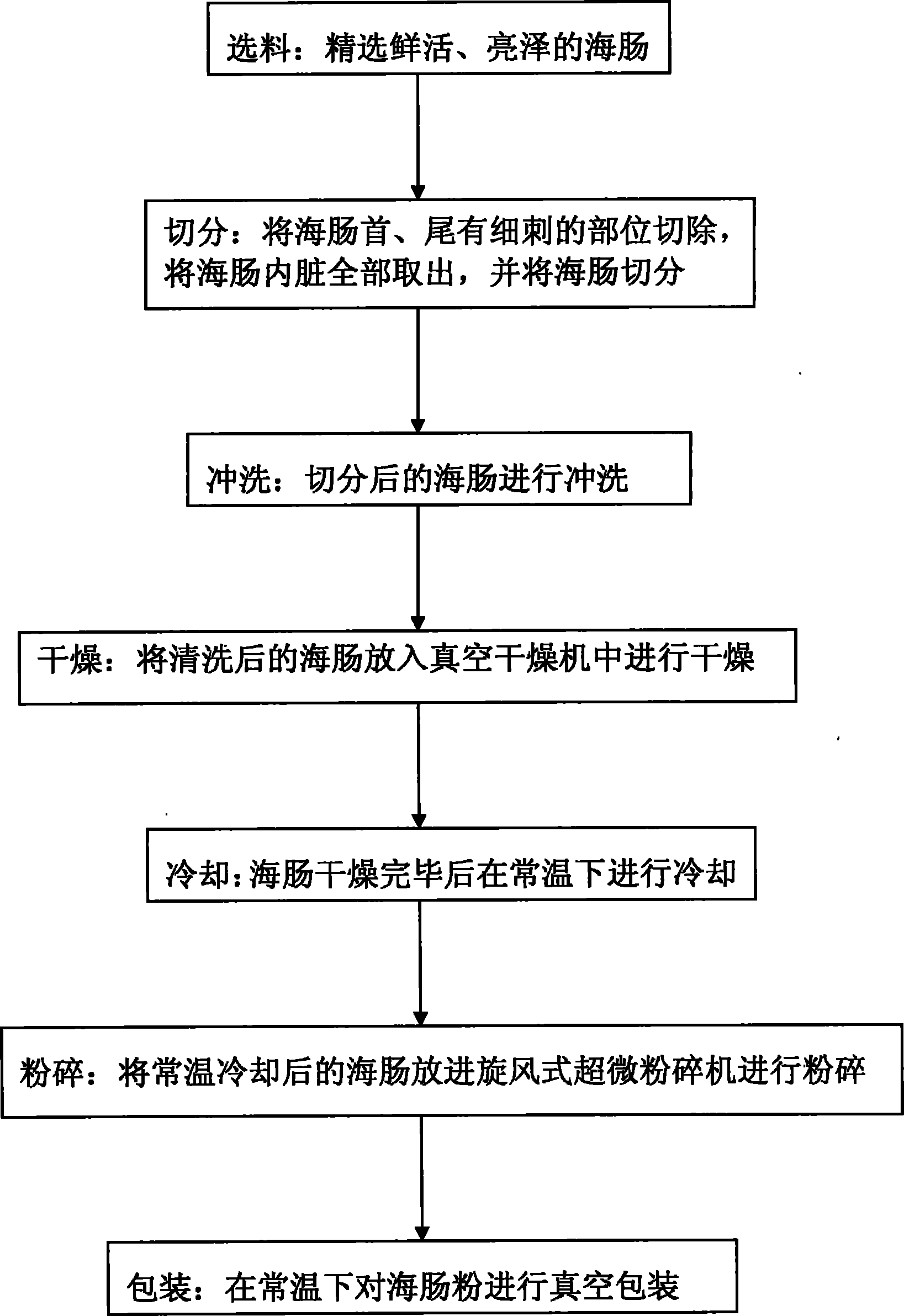

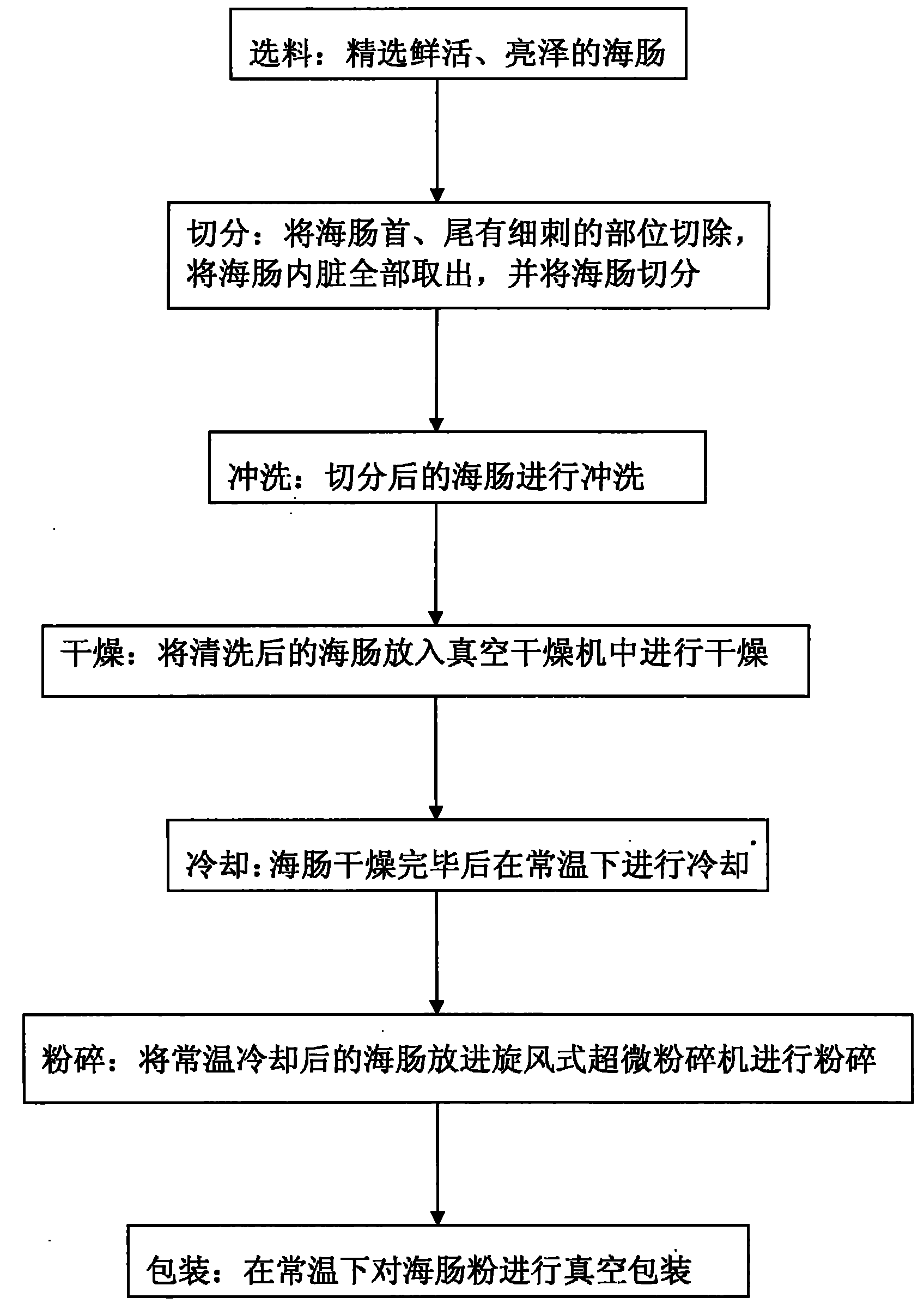

[0017] The following is a detailed description in conjunction with the drawings and embodiments:

[0018] As shown in Figure 1, a method for processing sea sausage powder of the present invention:

[0019] (1) Selection of ingredients: selected fresh and shiny sea intestines.

[0020] (2) Divide: Use a knife to excise the parts of the sea intestine with fine thorns at the head and tail, then cut the sea intestine longitudinally, take out all the internal organs of the sea intestine, and then cut the sea intestine into slices.

[0021] (3) Flushing: The sliced sea intestines are cut through the net-chain bubble cleaner to walk in the high-pressure tumbling bubbles for rough washing; then spray with high-pressure water, that is, use the aeration pump to pass through the pipes and pipe holes The tumbling bubbles sprayed from the bottom of the spray barrel make the sea intestines achieve the purpose of fine washing. During the washing, the divided sea intestines are constantly tumbling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com