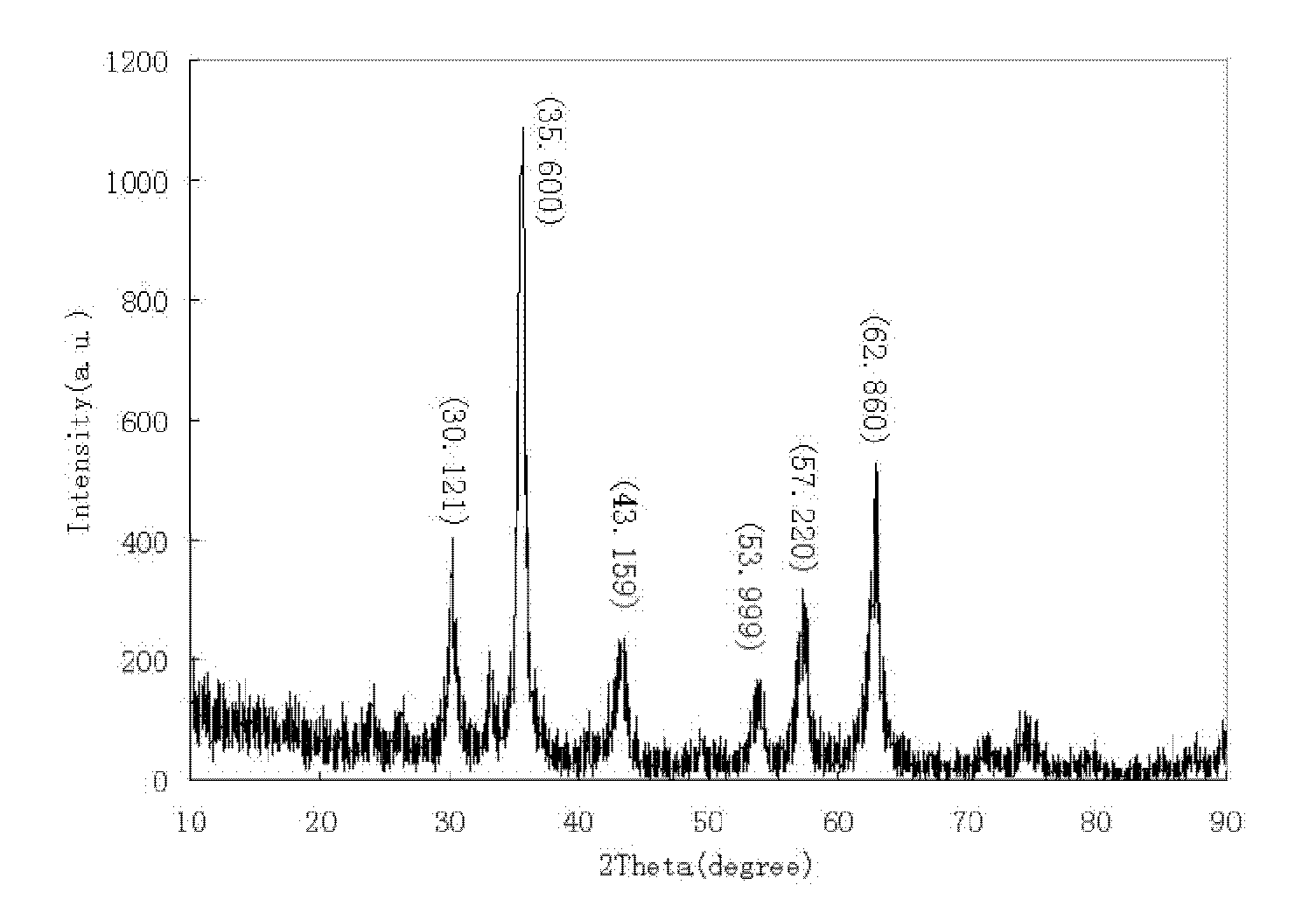

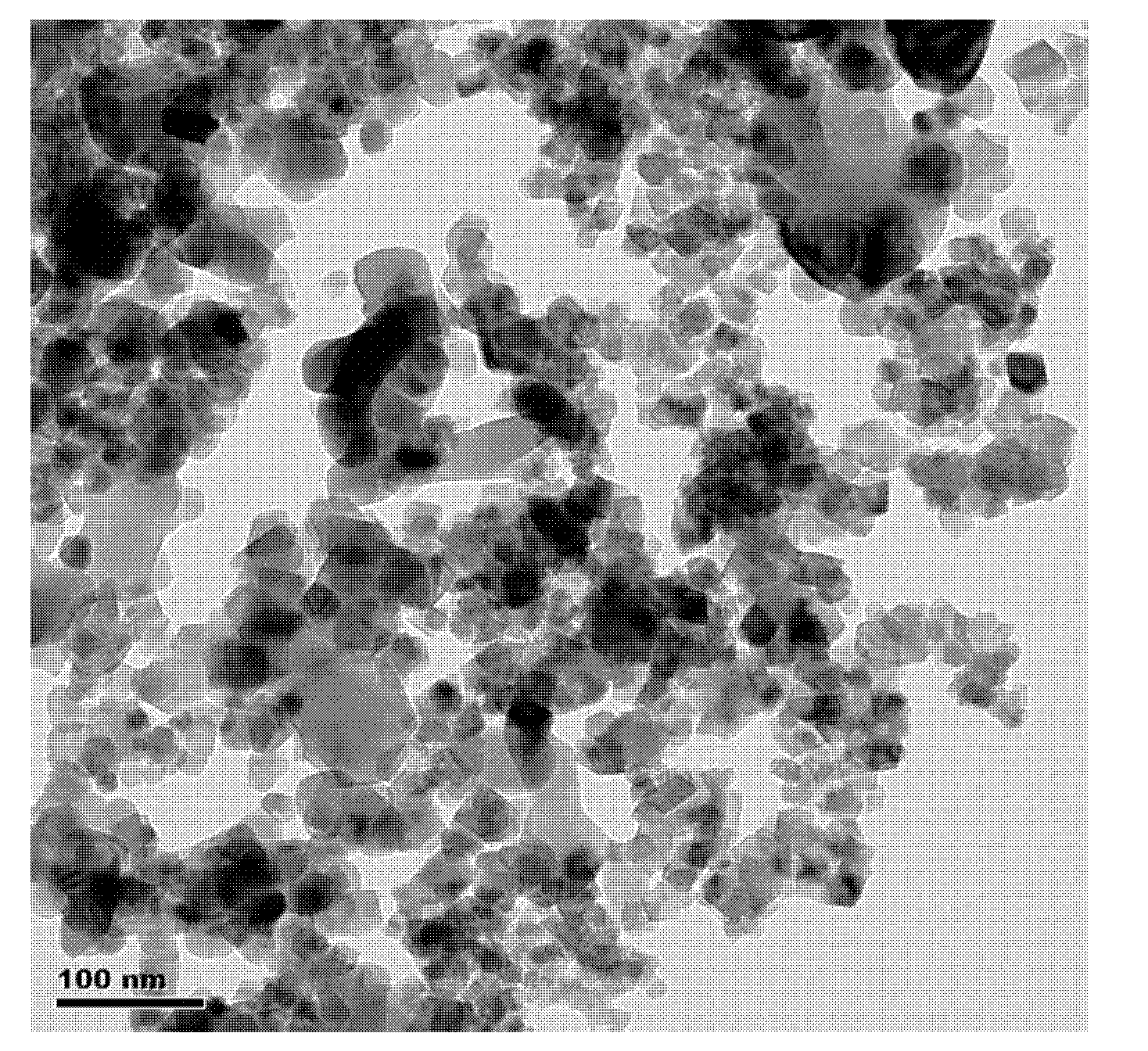

Preparation method of nano magnesium ferrite

A technology of nanometer iron and magnesium acid, applied in nanotechnology, chemical instruments and methods, iron compounds, etc., can solve the problems of high energy consumption and complicated process, and achieve the effect of high purity, low cost and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0020] A preparation method of nano-magnesium ferrite, the specific preparation steps are as follows:

[0021] A. Take 2.77g FeCl 3 ·6H 2 O, 1.99 g FeCl 2 4H 2 O was placed in a beaker; 100ml of NaOH solution was added to prepare magnetic Fe by chemical co-precipitation 3 o 4 Nanoparticles;

[0022] B, with the magnetic Fe prepared by step A 3 o 4 Put the beaker of nanoparticles into a muffle furnace and bake at 500°C for 3-4h to obtain nano-Fe 2 o 3 ;

[0023] C. Weigh 3g of magnesium powder and place it in another beaker, add 60ml of deionized water, and process it in an ultrasonic cleaner with a frequency of 90Hz for 5-8h to obtain a white turbid solution, and absorb the upper turbid solution into a clean beaker middle;

[0024] D. Set the temperature of the constant temperature drying oven to 60°C, put the beaker containing the turbid li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com