Method for hydrofining light petroleum distillate

A light petroleum, hydrorefining technology, applied in chemical instruments and methods, refining to remove heteroatoms, catalyst supports, etc., can solve the problems of small specific surface area of oxides, low thermal stability, poor mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

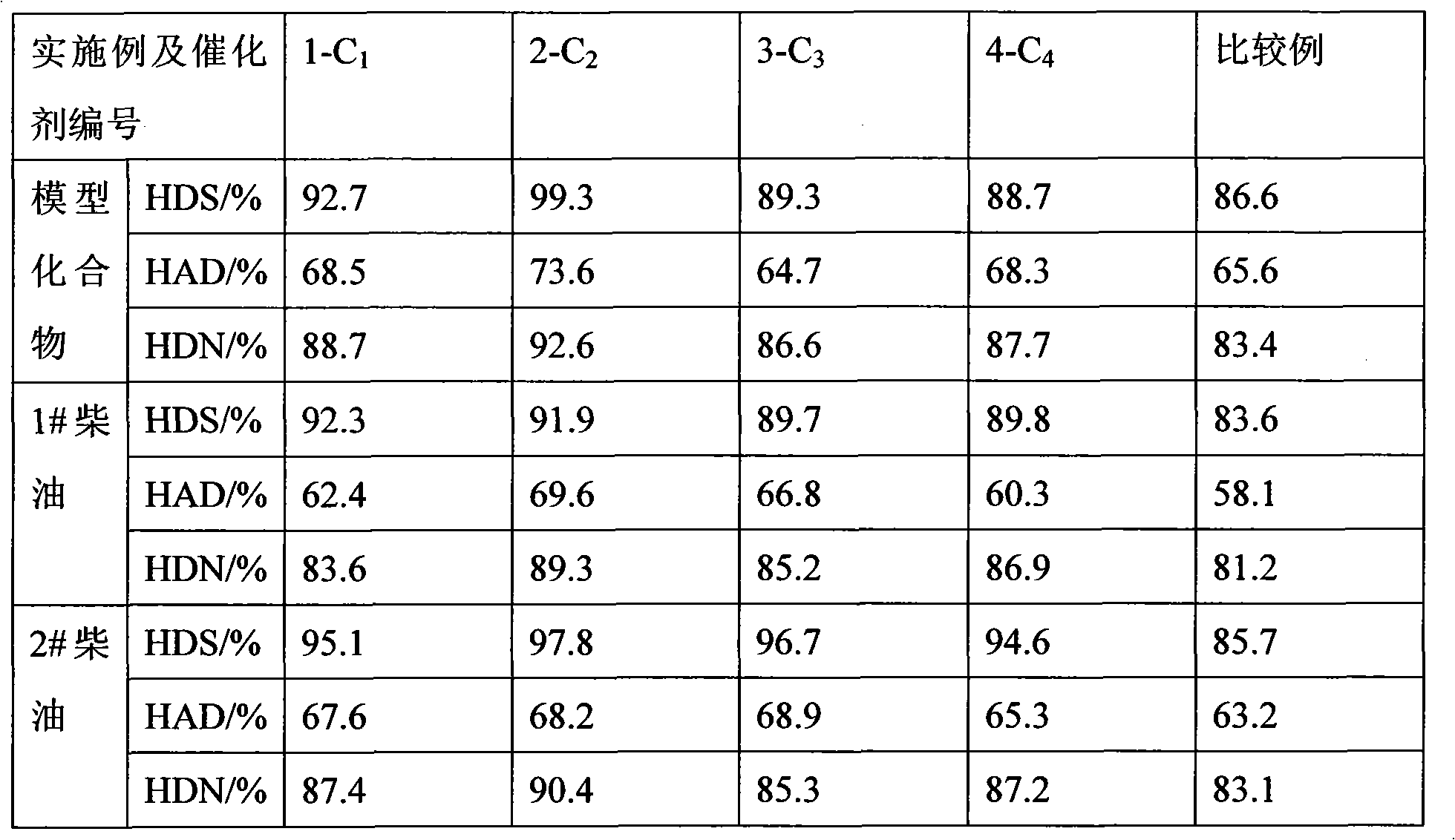

Examples

Embodiment 1

[0020] 1. Measure 22.0659g ZrOCl 2 ·8H 2 O was dissolved in 380ml of absolute ethanol to obtain solution A; measure 9.815ml of TiCl 4 Dissolve in 98.15ml absolute ethanol to obtain solution B.

[0021] 2. Titrate 57.7ml of silica sol into solution B to obtain solution C.

[0022] 3. Then titrate solution C into solution A, stir thoroughly for 1 hour, and make a uniform silicon-titanium-zirconium mixed solution D.

[0023] 4. Under constant stirring, use solution D to titrate 360mL polyethylene glycol-1000 ammonia solution for precipitation, monitor at any time during the second half of the titration, if necessary, add ammonia water dropwise to control the pH value at 9-10 Between, and then let stand for 24h.

[0024] 5. Suction filter and wash the precipitate until there is no Cl - The precipitate was washed twice with absolute ethanol.

[0025] 6. Dry the precipitate at 120° C. for 12 hours to obtain an oxide precursor. Then place the precursor in a muffle furnace, hea...

Embodiment 2

[0030] 1. Measure 3.01g ZrOCl 2 ·8H 2 O was dissolved in 52ml of absolute ethanol to obtain solution A; measure 29.60ml of TiCl 4 Dissolve in 296ml absolute ethanol to obtain solution B.

[0031] 2. Titrate 9.2ml of silica sol into solution B to obtain solution C, and stir for a certain period of time.

[0032] 3. Add solution C dropwise to solution A, stir well for 1 hour, and make a uniform silicon-titanium-zirconium mixed solution D.

[0033] 4. Under continuous stirring, use solution D to titrate 260mL polyethylene glycol-1000 ammonia solution for precipitation, monitor at any time during the second half of the titration, if necessary, add ammonia water dropwise to control the pH value at 9-10 Between, and then let stand for 24h.

[0034] 5. Suction filter and wash the precipitate until there is no Cl - Then, wash twice with absolute ethanol.

[0035] 6. Dry the washed precipitate at 120° C. for 12 hours to obtain a white powder oxide precursor. Then place the precu...

Embodiment 3

[0040] 1. Measure 22.36g ZrOCl 2 ·8H 2 O was dissolved in 385ml of absolute ethanol to obtain solution A; measure 4.41ml of TiCl 4 Dissolve in 44ml absolute ethanol to obtain solution B.

[0041] 2. Titrate 15.3ml of silica sol into solution B to obtain solution C.

[0042] 3. Then titrate solution C into solution A, stir thoroughly for 1 hour, and make a uniform silicon-titanium-zirconium mixed solution D.

[0043] 4. Under constant stirring, use solution D to titrate 300mL polyethylene glycol-1000 ammonia solution for precipitation, monitor at any time during the second half of the titration, if necessary, add ammonia water dropwise to control the pH value at 9-10 Between, and then let stand for 24h.

[0044] 5. Suction filter and wash the precipitate until there is no Cl - Then, wash twice with absolute ethanol.

[0045] 6. Dry the precipitate at 120° C. for 12 hours to obtain a white powder oxide precursor. Then place the precursor in a muffle furnace, heat up to 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com