High polymer curtain grouting drilling tool and hole pattern construction method

A technology of curtain grouting and high polymer, which is applied in water conservancy projects, sea area engineering, construction, etc., can solve problems such as low efficiency, soil punching damage, large disturbance or damage of dam body, etc., and achieve broad social benefits and enhanced Good anti-seepage performance and anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

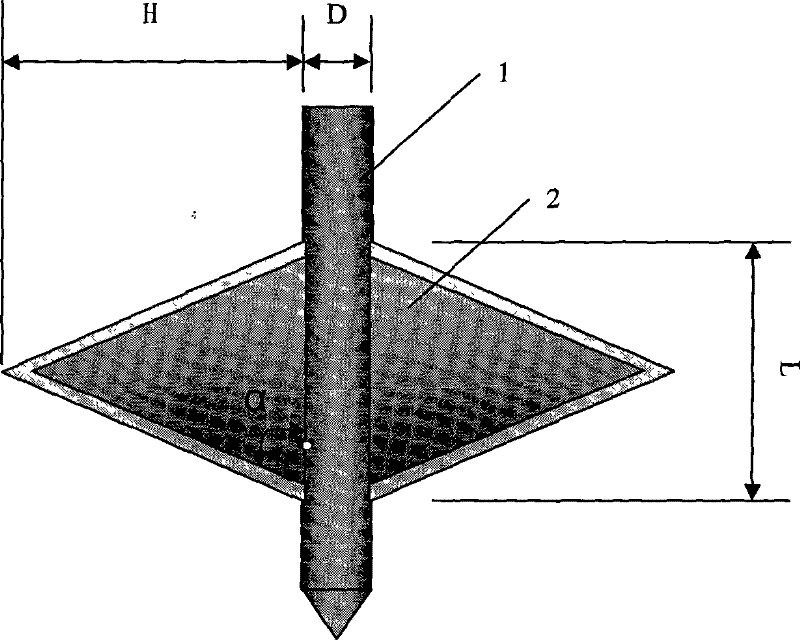

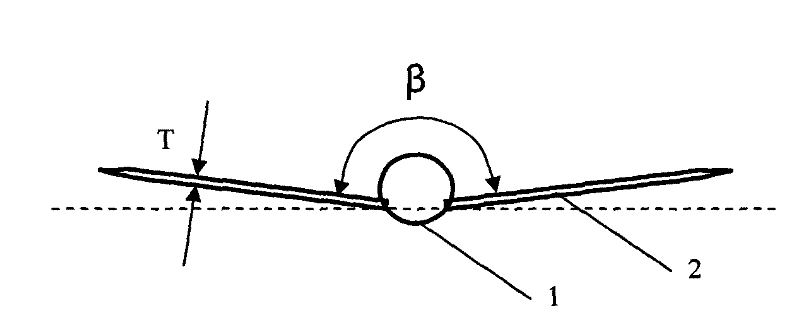

[0026] Embodiment: The polymer curtain grouting drilling tool is a wide airfoil drilling tool, that is, two wider wings 2 are welded on both sides of the circular drilling rod 1; the diameter D of the cone probe of the circular drilling rod 1 is 40- 50mm, the wings 2 on both sides of the drill pipe 1 are two triangular steel plates welded symmetrically with cutting edges, the bottom width L is 500-1000mm, the height H is 300-600mm, the angle α between the bottom sides is 20-30 degrees, and the thickness T is 10-20mm, and the angle β between the wings 2 on both sides of the drill pipe 1 is 160-170 degrees, such as figure 1 and figure 2 shown. The specific size of each part can be determined according to the actual situation of the project.

[0027] The construction method of the high polymer curtain grouting hole mold is to construct the curtain grouting hole mold by using the high polymer curtain grouting drilling tool and the static pressing method. The specific implement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com