High voltage discharge tube

A high-voltage discharge and discharge tube technology, used in cold cathode tubes, solid cathode components, etc., can solve the problems of unstable discharge voltage, influence of humidity and air pressure, and can not continue to use, etc., to achieve stable discharge voltage, fast discharge speed, Fast recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

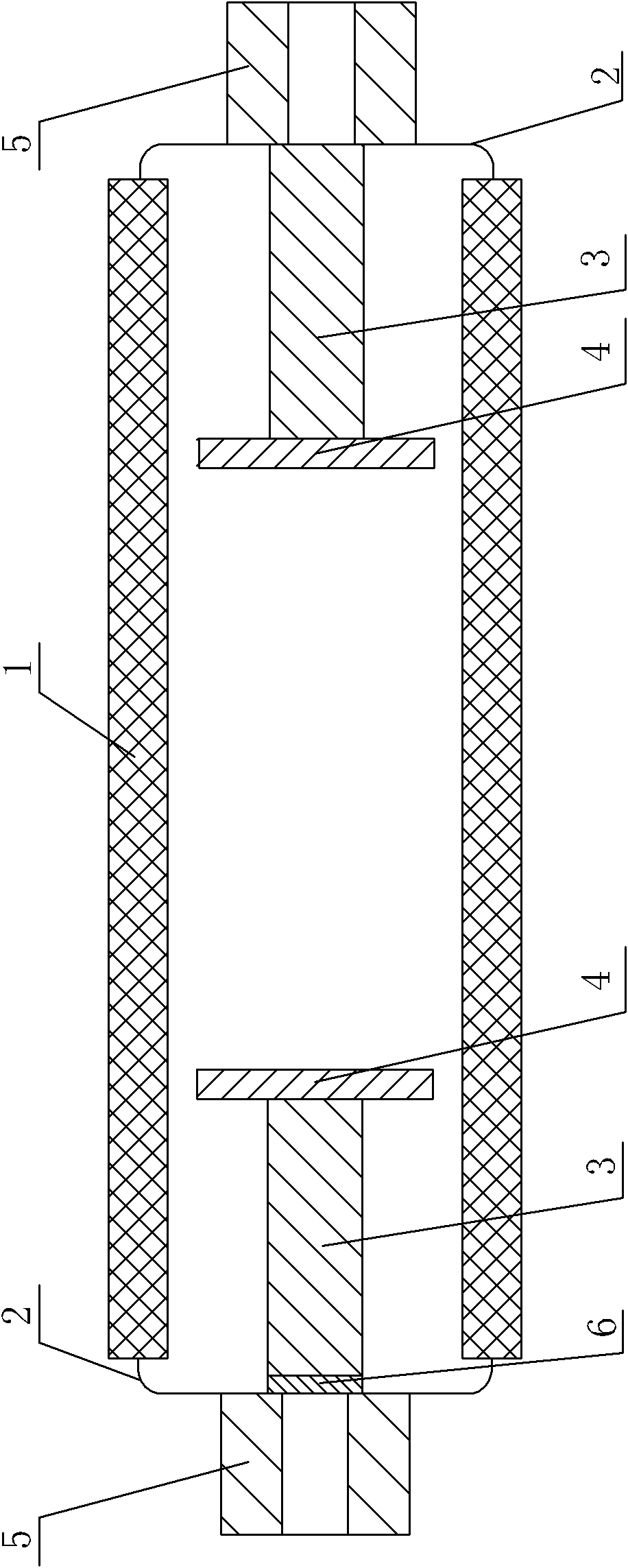

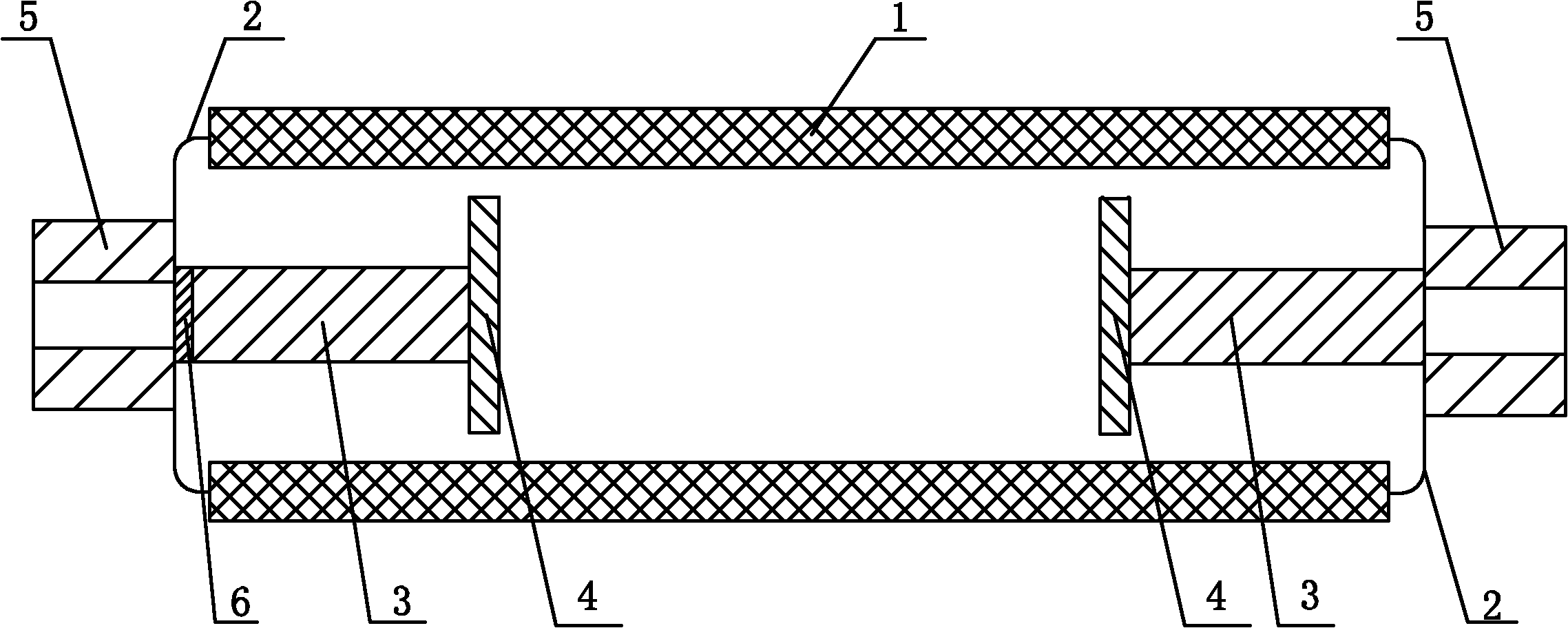

[0022] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0023] Such as figure 1 As shown, the high-voltage discharge tube of the present invention includes an insulating tube 1 made of 95 porcelain, a connecting ring 2 welded to both ends of the insulating tube 1 for sealing the insulating tube 1, and a connecting ring 2 located on the insulating tube 1. The inner conductive rod 3 with one end fixedly connected to the connecting ring 2 on the corresponding side, the electrode 4 made of tungsten-molybdenum alloy fixed on the other end of each of the conductive rods 3, and the outer sides of the two connecting rings 2 Both are provided with terminal posts 5 for connecting the discharge tube to the circuit, the insulating tube 1 is filled with pure hydrogen for arc extinguishing, the conductive rod 3 is coaxially arranged with the insulating tube 1, and the connecting The ring 2, the conductive rod 3 and the terminal po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com