Method for injecting electrolyte into shell of battery

A technology of injecting electrolyte and electrolyte, which is applied in the direction of battery components, circuits, electrical components, etc., can solve the problems of easy volatilization of electrolyte, change of actual composition of electrolyte, cumbersome operation, etc. Injection time and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] The present invention will be further described below by way of examples. It should be noted that these examples do not limit the protection scope of the present invention.

preparation example

[0050] The battery involved in the embodiment of the present invention is an AA battery, and its preparation method is as follows:

[0051] FeS 2 The powder (natural pyrite collected from Yunfu, Guangdong) is used as the positive electrode active material, and the material is mixed with the conductive agent (graphite and acetylene black) to make the positive electrode powder. Use an organic solvent to make the adhesive into an adhesive, wherein the adhesive is styrene-ethylene / butylene-styrene block copolymer (SEBS, trade name Kraton G1651), and the organic solvent is produced by Shell A mixture of Shell A100 (aromatic solvent) and Shell OMS (isoparaffin), the mixing ratio is 4:6 (weight ratio).

[0052] The above positive electrode powder and binder are mixed in a weight ratio of 2:1 and then stirred to form a slurry. In the dry matter of the positive electrode slurry finally made, the weight ratio of each component is:

[0053] FeS 2 : 91% by weight; graphite: 6% by weig...

Embodiment 1

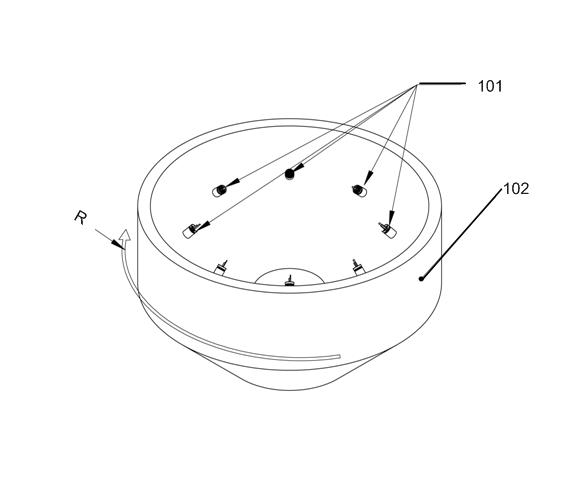

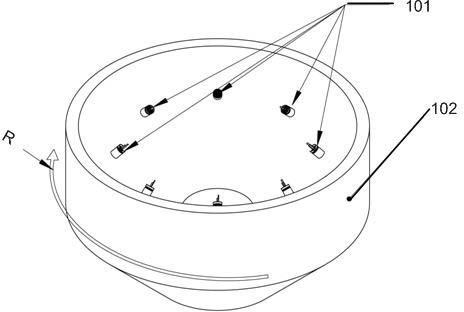

[0057] Get 10 battery casings without electrolyte obtained in the preparation example, weigh the battery weight, and place them symmetrically figure 1 On the centrifuge shown, the open end of the battery is close to the central axis of the centrifuge (rotation axis), and the closed end is away from the central axis of the centrifuge. The placement direction of the battery is 30° from the horizontal direction. The above-mentioned organic electrolytic solution was supplied into the case from the electrolytic solution supply device through the open end of the case. Then remove the electrolyte supply machine. Set the rotation speed of the centrifuge to 1200 rpm, start the centrifuge for 2 minutes, and then take out the battery.

[0058] Observe the electrolyte absorption of the battery and seal it, then weigh the battery again and calculate the electrolyte weight injected into each battery. The theoretical empty volume in the AA-type lithium-iron disulfide battery casing is cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com