Active control drive power supply for shape memory alloy

A technology of memory alloy and active control, which is applied in the direction of electrical components, machines/engines, mechanisms that generate mechanical power, etc. It can solve the problems that the adhesive control effect is greatly affected, the thickness of the adhesive is difficult to control, and it is difficult to reduce the vibration of the sailboard. Achieve the effect of increasing the adjustable range, simple structure and large output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

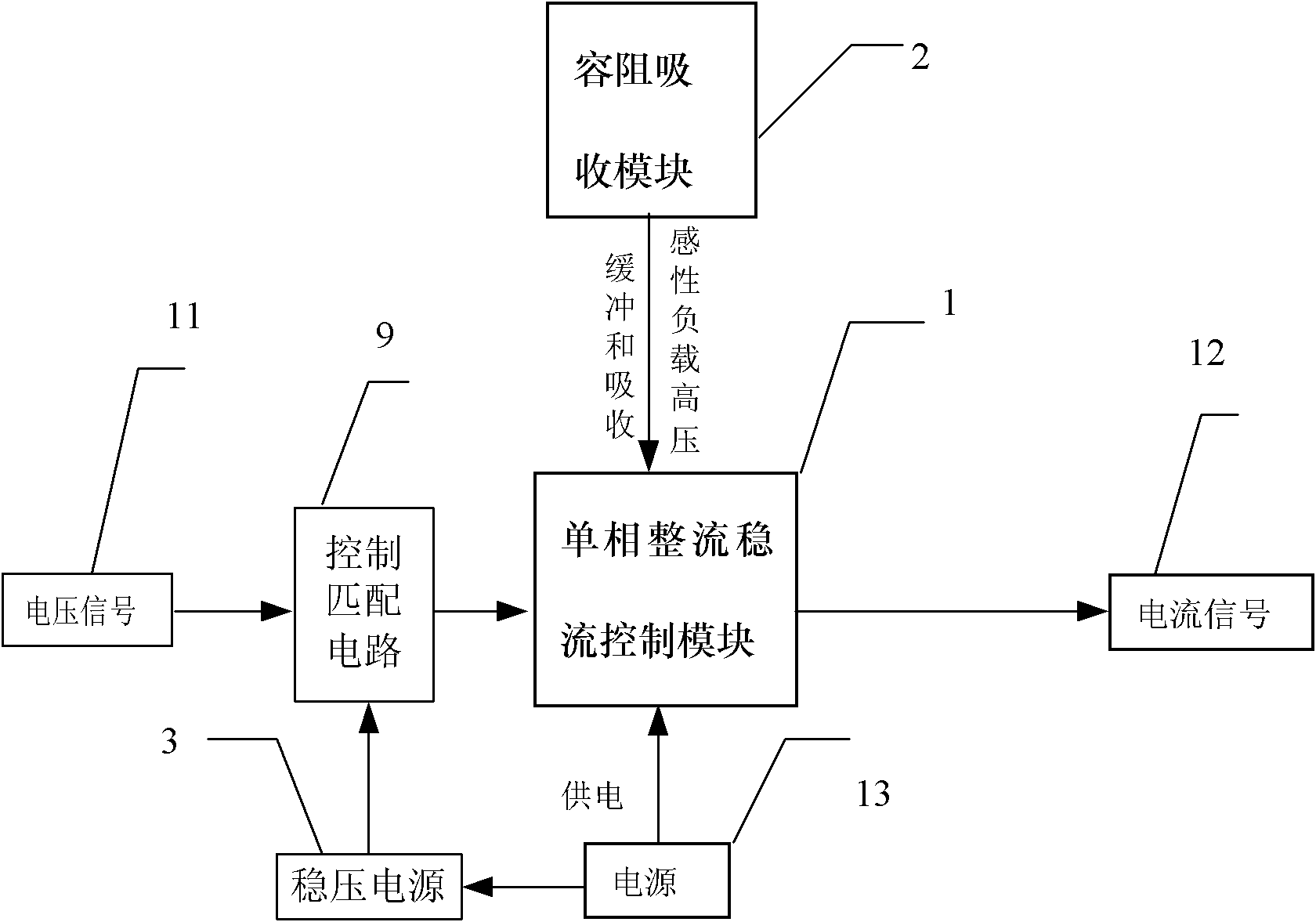

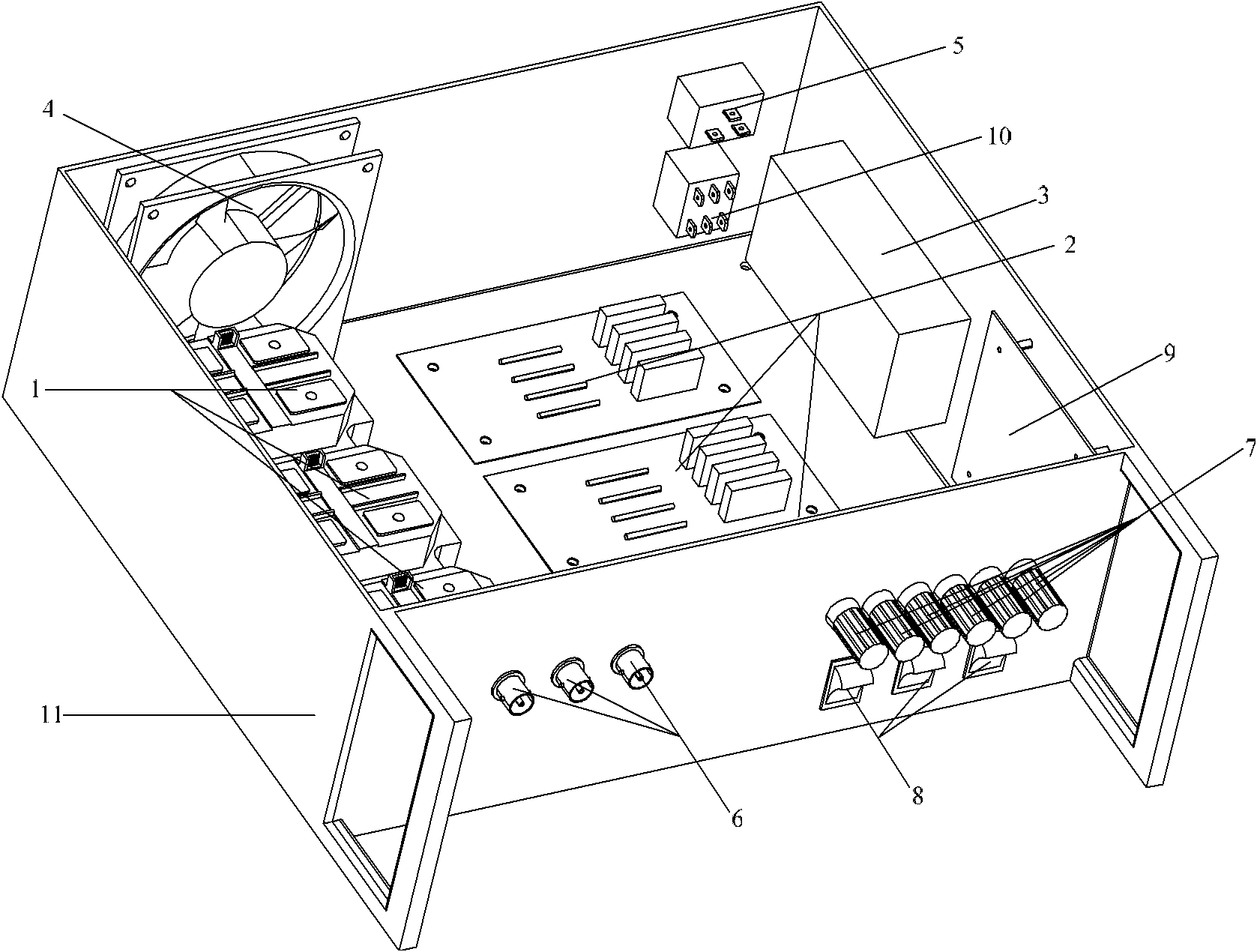

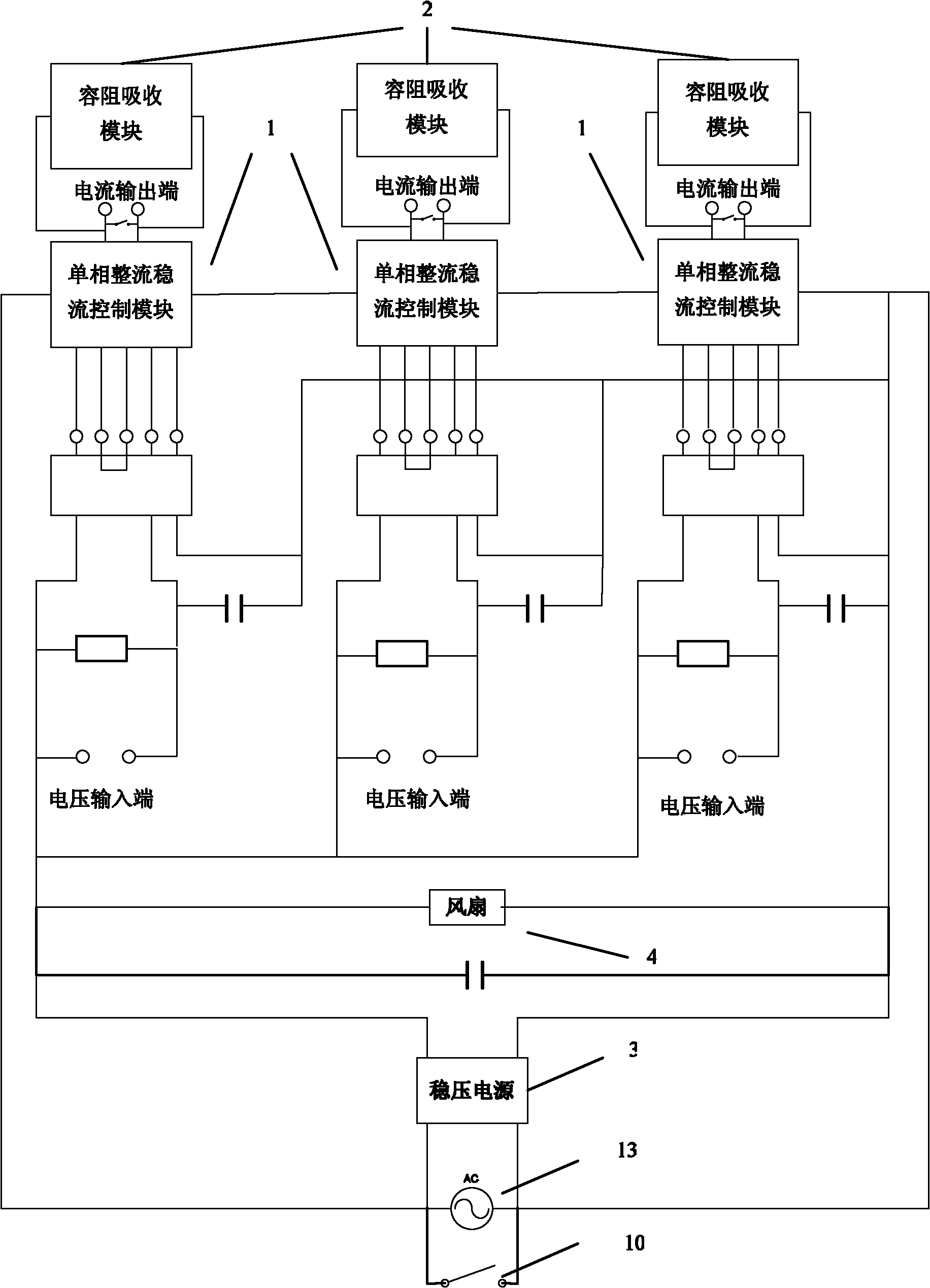

[0020] Such as figure 1 , 3 As shown, the drive power supply of the present invention includes a power supply chassis structure and circuit components. The circuit part includes a control matching circuit 9 , a regulated power supply 3 , a 220V AC power supply 13 , a single-phase rectification and constant current control module 1 , and a capacitive resistance absorption module 2 . The voltage signal 11 is input through the data line as the input terminal of the power supply of the present invention. The control matching circuit 9 processes the transmitted voltage signal 11 , including capacitive low-pass filtering to prevent the circuit from being burned due to excessive voltage signal. The regulated power supply 3 provides a 12V DC regulated power supply for the control matching circuit 9 , and the 220V AC power supply 13 provides electric energy for the regulated power supply 3 and the single-phase rectification and current stabilization control module 1 . The capacitiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com