Method for fabricating circuit board

A circuit board production and circuit substrate technology, which is applied in the secondary treatment of printed circuits, coating of non-metallic protective layers, etc., can solve the problems of circuit board product defects, product defects, pollution, etc., to avoid product defects and improve yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The circuit board manufacturing method provided by the technical solution will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] A method for manufacturing a circuit board provided in the first embodiment of the technical solution, the method for manufacturing a circuit board includes the steps of:

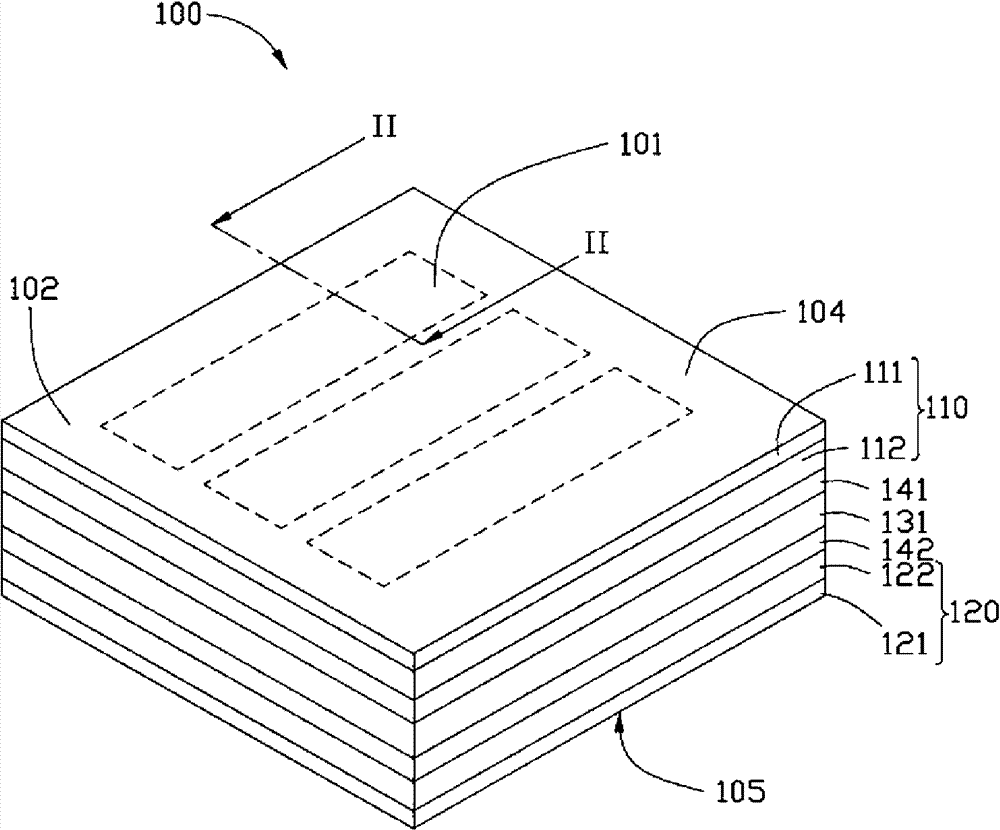

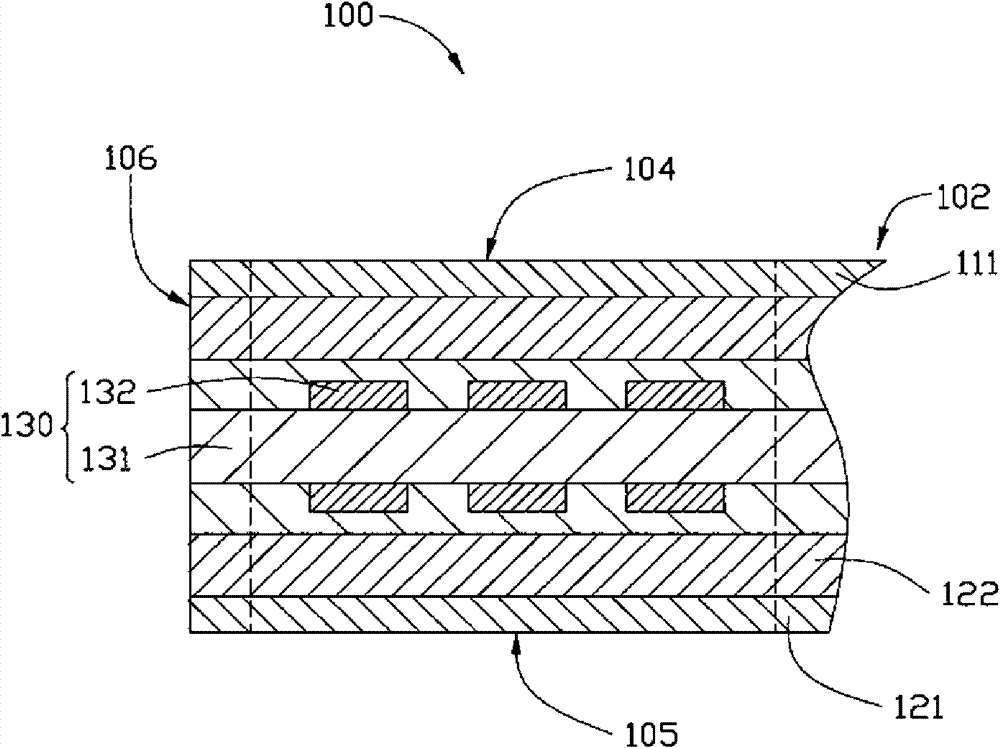

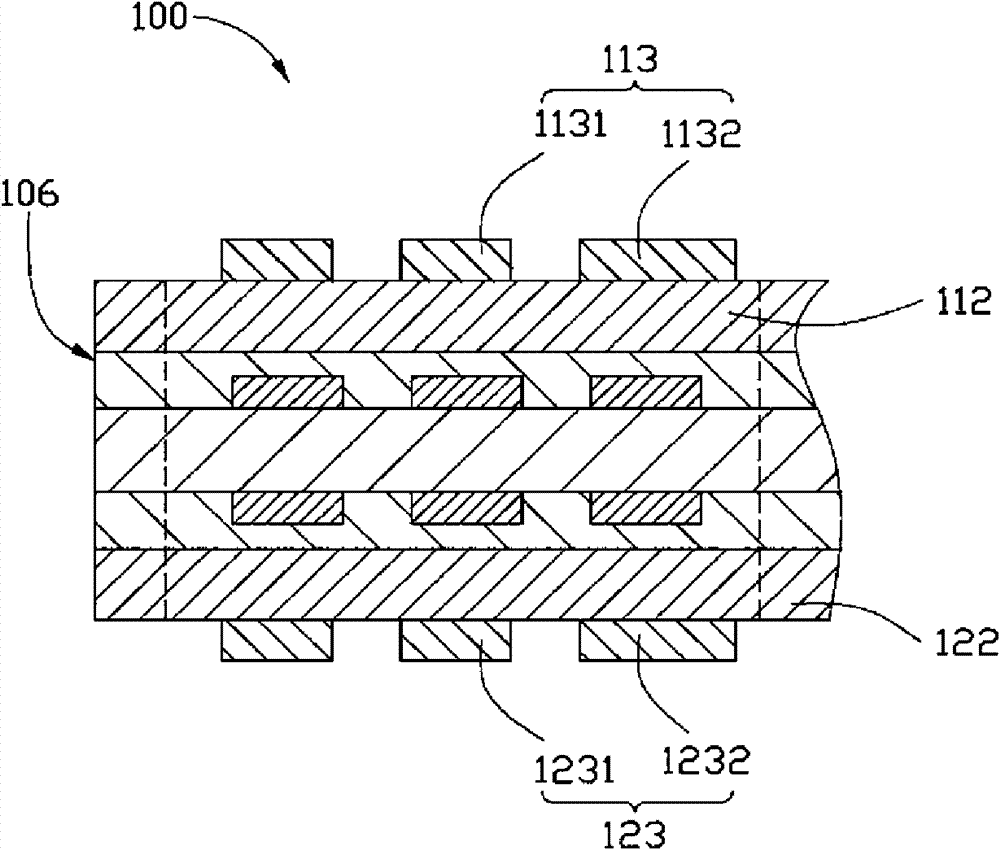

[0020] see figure 1 and figure 2 , the first step is to provide a circuit substrate 100 .

[0021] The circuit substrate 100 may be a single-sided copper-clad laminate or a double-sided copper-clad laminate, and the double-sided copper-clad laminate may also be a circuit substrate 100 formed by laminating a plurality of double-sided copper-clad laminates with circuit patterns formed on the surface with a single-sided copper-clad laminate. . In this embodiment, the circuit substrate 100 is formed by laminating the first copper-clad laminate 110 , the first adhesive layer 141 , the double-sided copper-clad laminate 130 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com