Positive photosensitive composition and permanent resist

A photosensitive composition and resist technology, applied in the direction of photosensitive material processing, optics, light source, etc., can solve the problems of insufficient heat resistance and chemical resistance, and achieve high transparency and excellent resistance to changes over time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

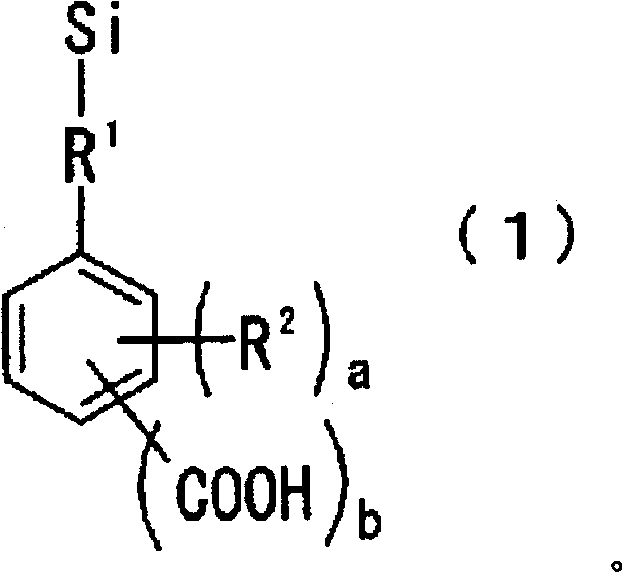

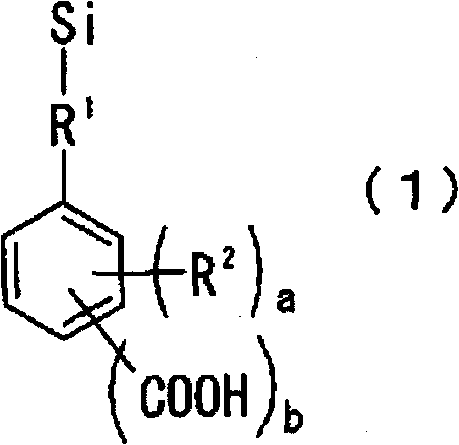

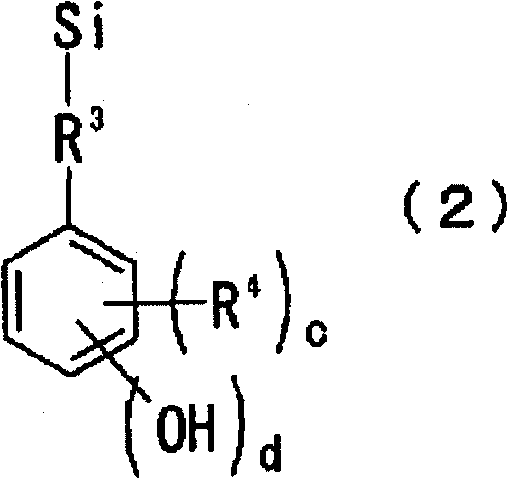

Method used

Image

Examples

Embodiment 1~11 and comparative example 1~16

[0261] [Examples 1-11 and Comparative Examples 1-16] Preparation of positive photosensitive composition

[0262] The positive photosensitive composition of Examples 1-11 and Comparative Examples 1-16 was prepared after mixing with the ratio shown in [Table 1], and filtering with the filter whose pore diameter is 0.2 micrometers. In addition, additional solvents were added so as to achieve the values in the table.

[0263] [Table 1]

[0264]

[0265] Solvent PGMEA: 1-methoxy-2-propanol acetate

[0266] DAA: diacetone alcohol

[0267] GBL: gamma-butyrolactone

[0268] The following evaluation was performed about the positive photosensitive composition of Examples 1-11 and Comparative Examples 1-16. The results are shown in [Table 2].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com