Interconnect for a fuel cell, a method for manufacturing an interconnect for a fuel cell

A technology of fuel cells and interconnects, applied in the field of interconnects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

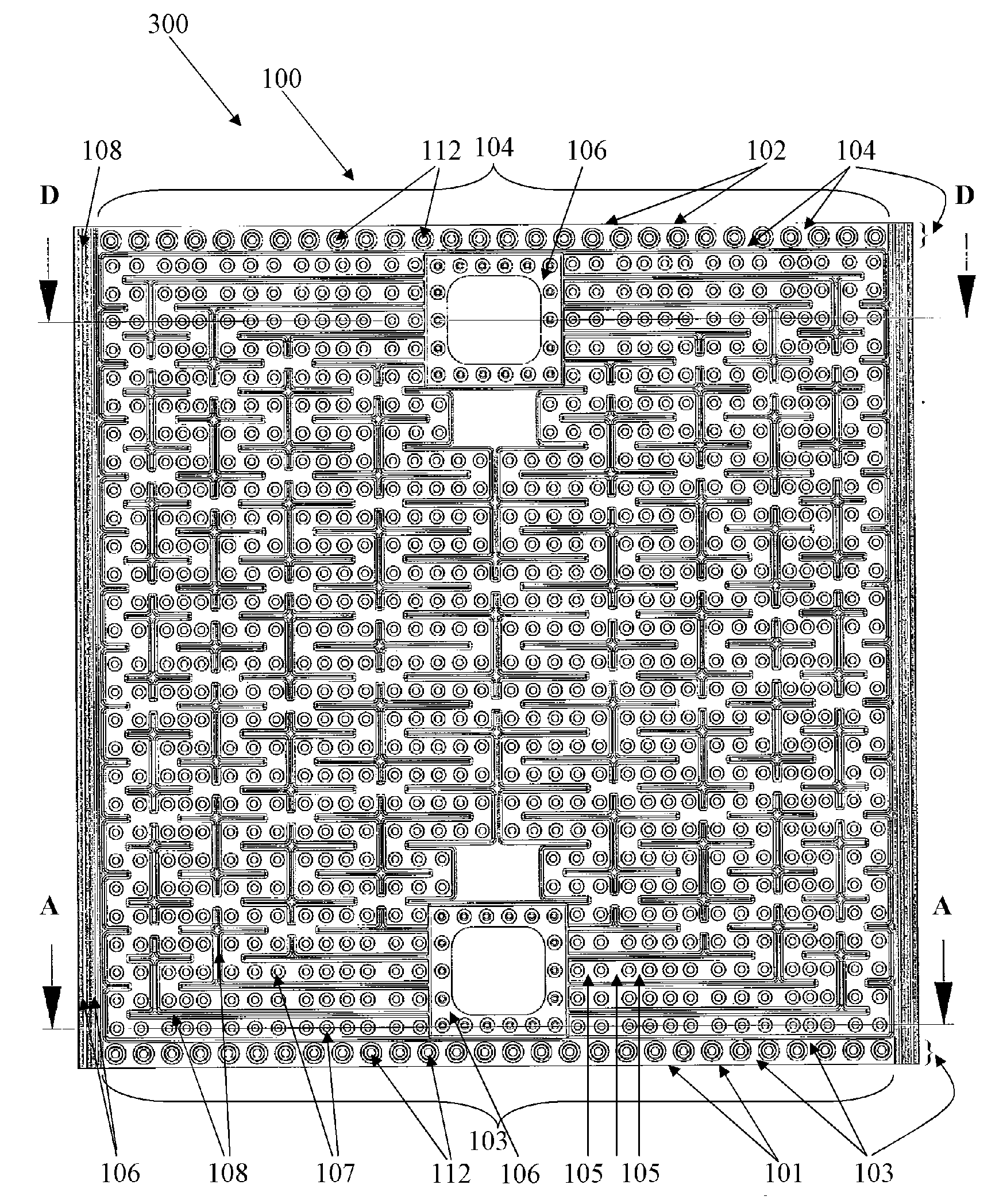

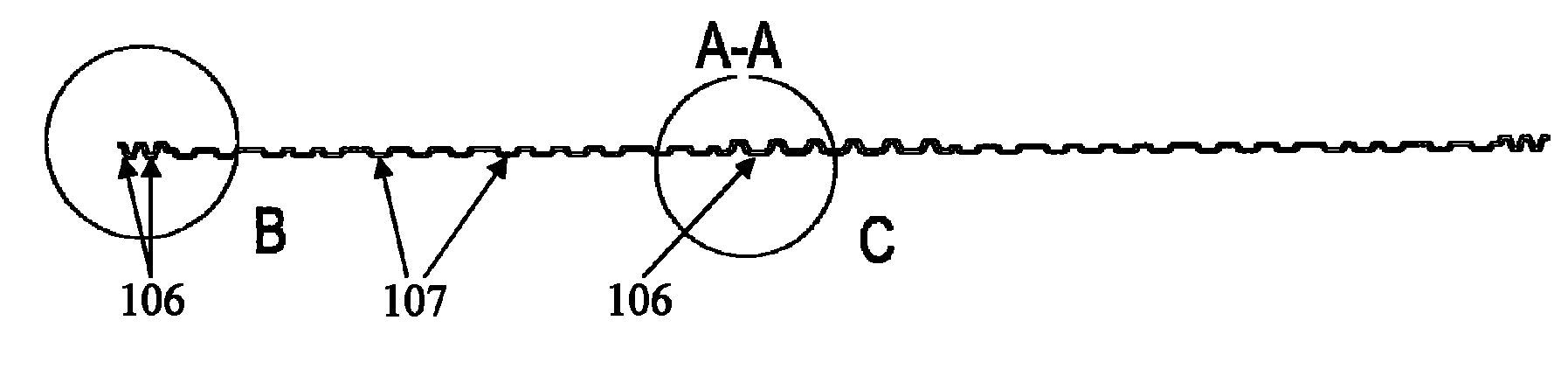

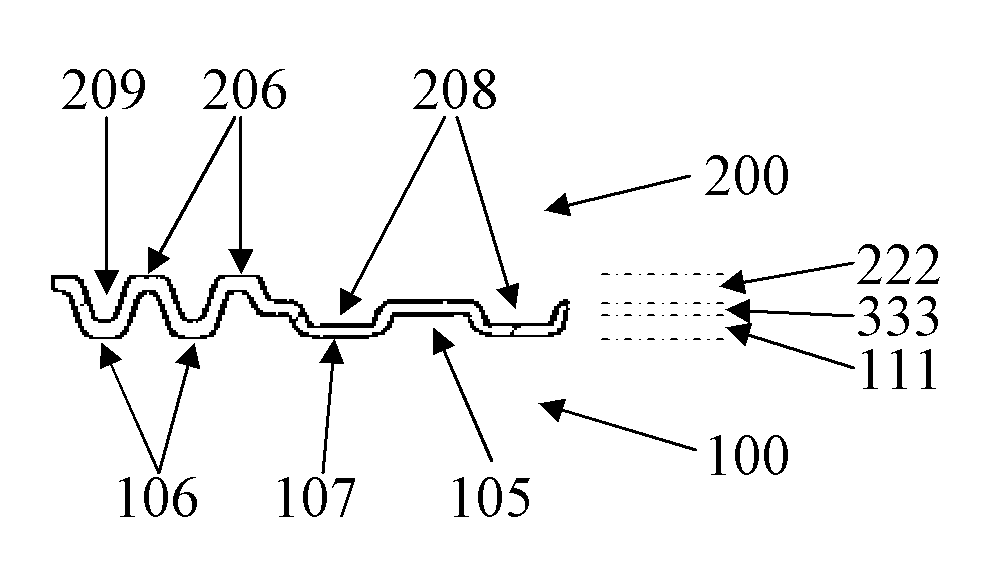

[0140] Figure 1-O A first side 100 of an interconnect 300 in the form of a rectangular plate defining four interconnect peripheral edges is shown. The interconnect shown here has a first side 100 on one face of the interconnect and a second side 200 on the opposite side shown in FIG. 2 , in this example the first side 100 is the interconnect The oxidant side of the member, the second side 200 is the fuel side of the interconnect. Oxidant gas, such as air, from an inlet oxidant manifold (not shown) is introduced into a first side oxidant inflow port 101 that extends along a relatively large portion of one peripheral edge of the interconnect. This type of inlet is characterized by an external manifold arrangement that directs flow to the inlet via an external manifold (not shown) that is sealed to the outer surface of the assembled fuel cell stack comprising A plurality of fuel cells according to the interconnection of the present invention.

[0141] Through the first side in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com