A kind of one-time welding method

A welding method and one-time technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency and impact on product welding quality, achieve high welding efficiency, protect physical and mental health, and improve the working environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of disposable welding method, comprises the following steps:

[0017] The first step is to butt the two sections of the main cylinder composed of carbon steel and 1Cr18Ni9Ti welding. The wall thickness of the body is greater than 6-10mm, and the diameter of the cylinder is 800-1000mm;

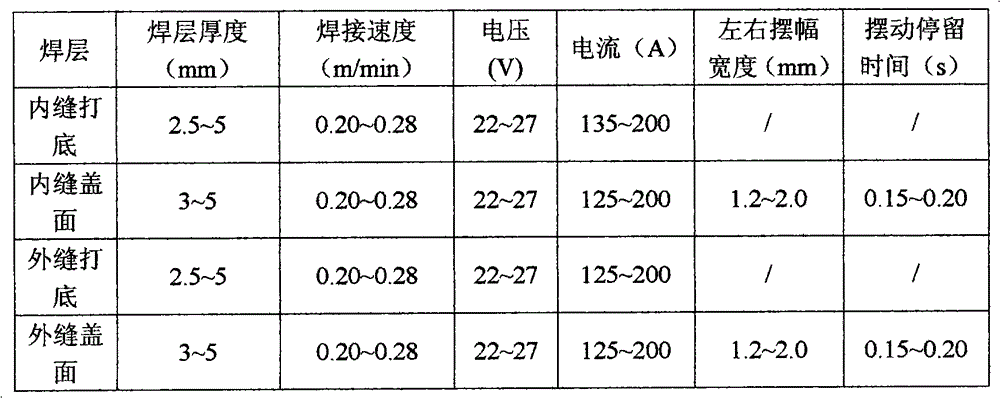

[0018] In the second step, a fully automatic MAG welding machine is used for internal seam welding, the welding wire is DW-309L flux-cored welding wire, and the shielding gas is 100% CO 2 , select the current, voltage, welding thickness and welding speed when the inner seam is bottoming, and the swing amplitude and swing dwell time when the inner seam is covered are determined by combining the selected parameters of current, voltage, welding layer thickness and welding speed. For parameter selection, see Schedule;

[0019] In the third step, the outer seam is cleaned by arc gouging, and then welded by a fully automatic MAG welding machine. The welding wire is DW-309L flux-cored ...

Embodiment 2

[0024] A kind of disposable welding method, comprises the following steps:

[0025] The first step is to butt the two sections of the main cylinder composed of carbon steel and 1Cr18Ni9Ti welding. The wall thickness of the body is greater than 10-16mm, and the diameter of the cylinder is 1000-1400;

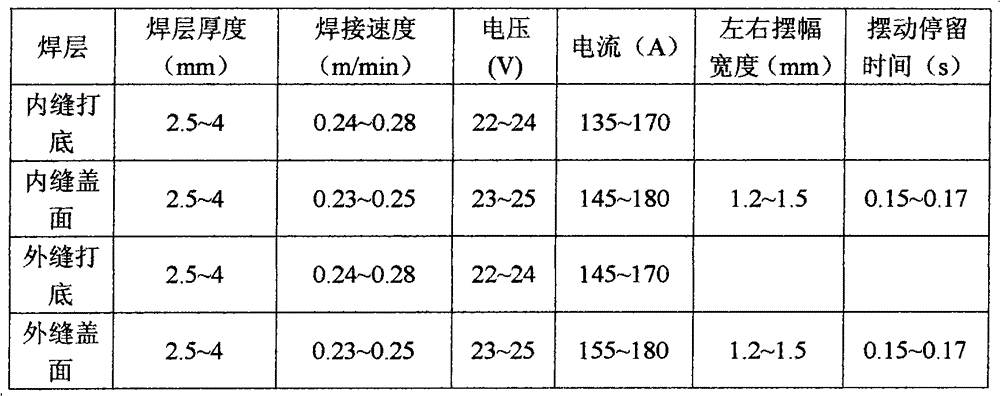

[0026] In the second step, a fully automatic MAG welding machine is used for internal seam welding, the welding wire is DW-309L flux-cored welding wire, and the shielding gas is 100% CO 2 , select the current, voltage, welding thickness and welding speed when the inner seam is bottoming, and the swing amplitude and swing dwell time when the inner seam is covered are determined by combining the selected parameters of current, voltage, welding layer thickness and welding speed. For parameter selection, see Schedule;

[0027] In the third step, the outer seam is cleaned by arc gouging, and then welded by a fully automatic MAG welding machine. The welding wire is DW-309L flux-cored ...

Embodiment 3

[0032] A kind of disposable welding method, comprises the following steps:

[0033] The first step is to butt the two sections of the main cylinder composed of carbon steel and 1Cr18Ni9Ti welding. The wall thickness of the body is greater than 16-22mm, and the diameter of the cylinder is more than 1400mm;

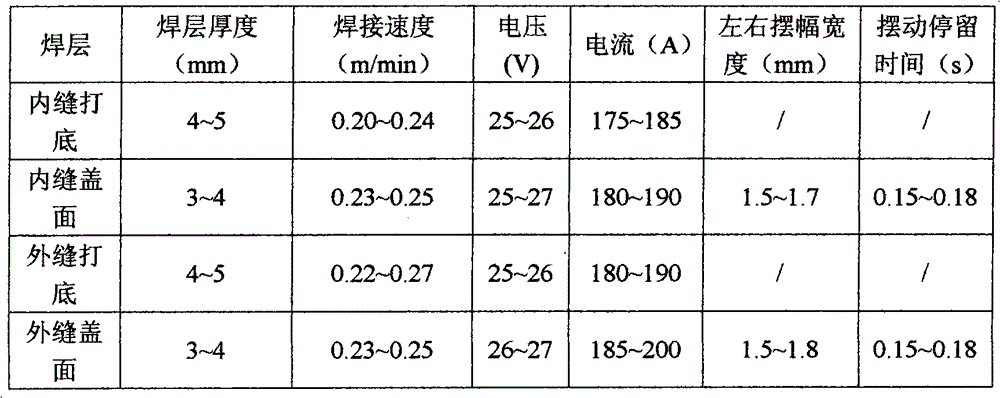

[0034] In the second step, a fully automatic MAG welding machine is used for internal seam welding, the welding wire is DW-309L flux-cored welding wire, and the shielding gas is 100% CO 2 , select the current, voltage, welding thickness and welding speed when backing the inner seam, and determine the swing amplitude and swing dwell time when covering the inner seam in combination with the selected parameters of current, voltage, welding layer thickness and welding speed. For parameter selection, see Schedule;

[0035] In the third step, the outer seam is cleaned by arc gouging, and then welded by a fully automatic MAG welding machine. The welding wire is DW-309L flux core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com