Caustic soda evaporating method using heat-conducting oil for heating

A heat-conducting oil heater, heat-conducting oil technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of difficult operation, large investment in fixed assets, and high energy consumption, and achieve The effect of reducing investment, large production capacity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

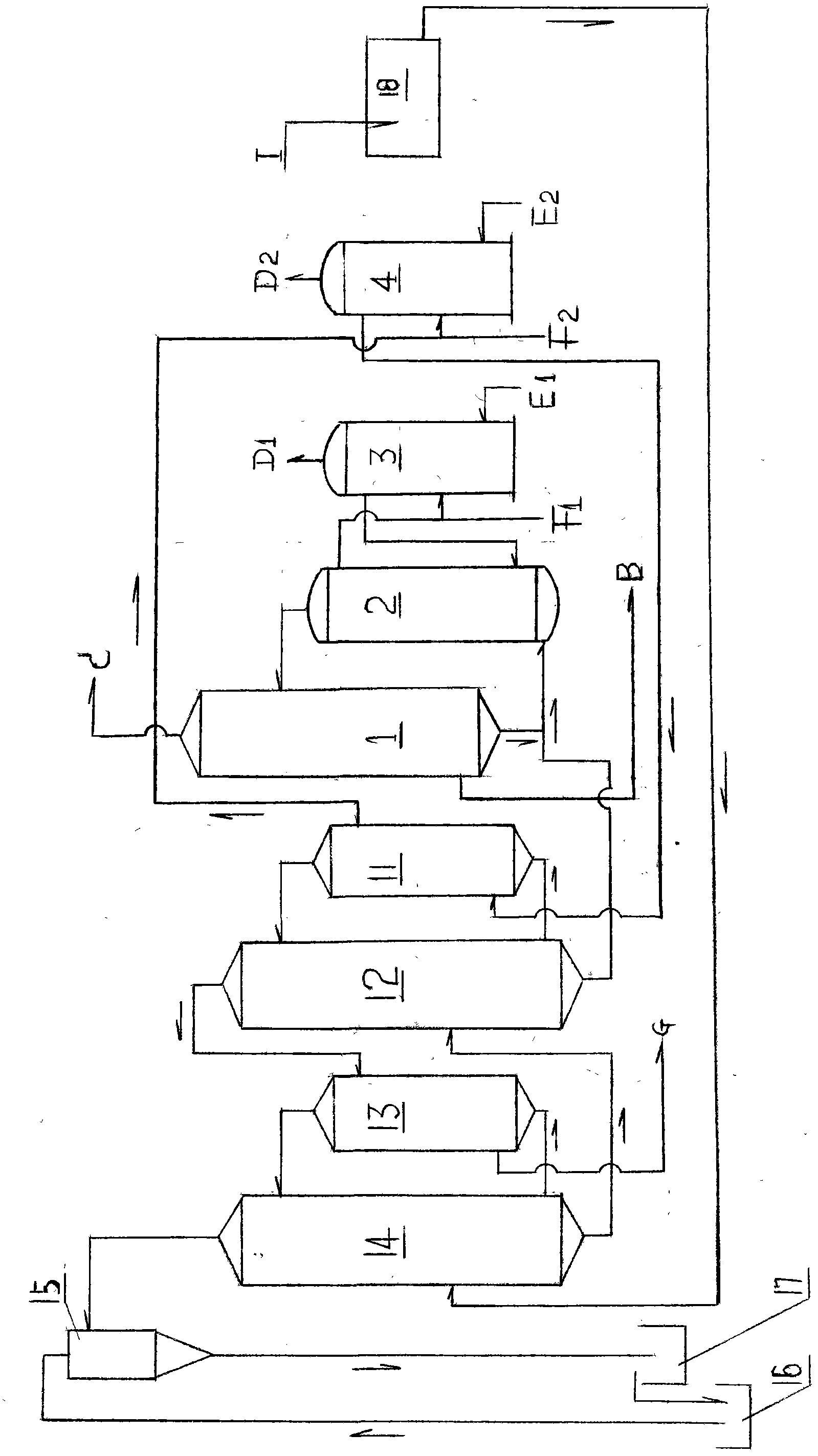

[0035] Manufacture and install a heat transfer oil evaporation device with an annual output of 100,000 tons of caustic soda.

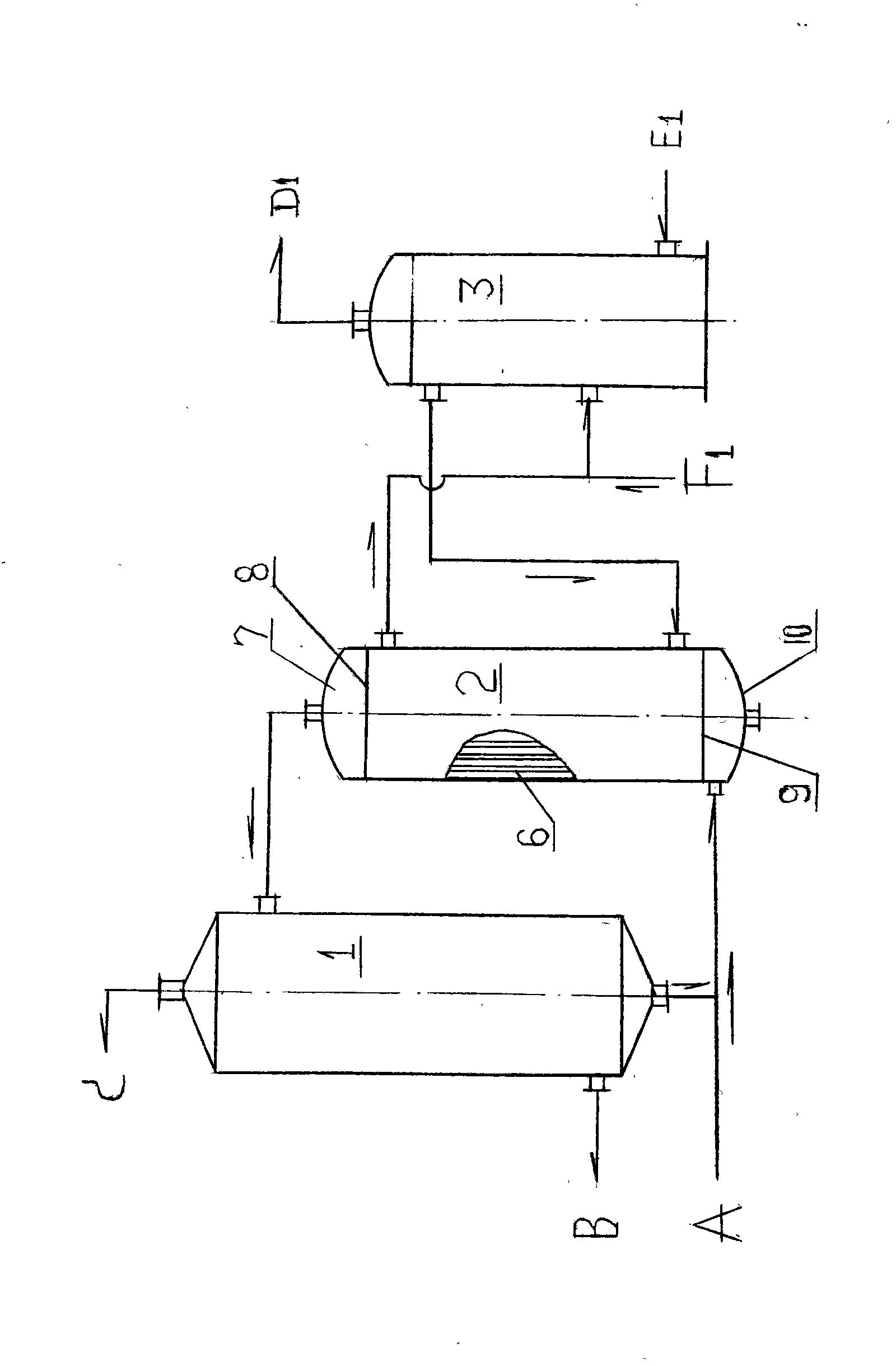

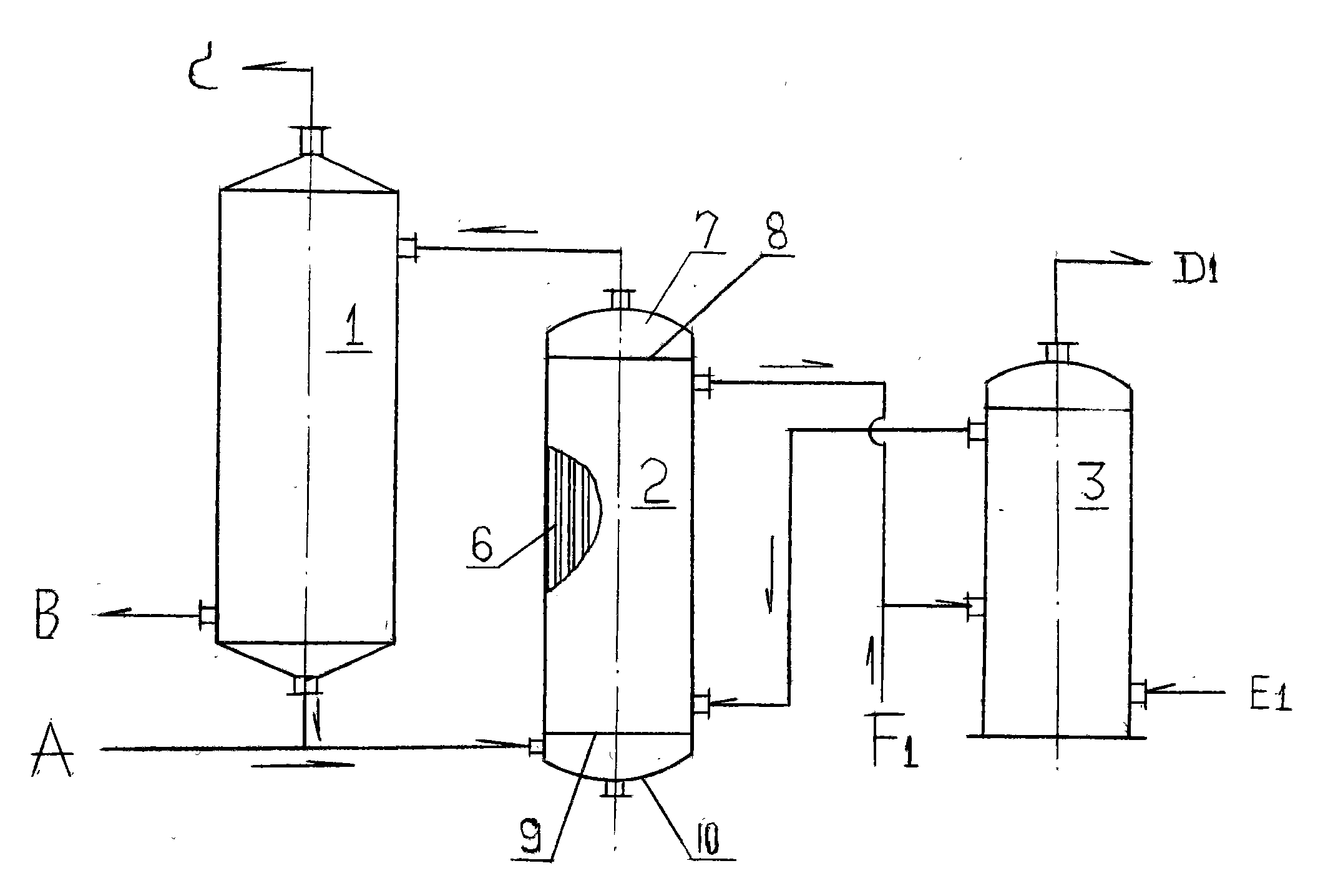

[0036] 1. According tofigure 1 , figure 2 Fabrication and installation of two thermal oil heaters.

[0037] After calculation, the diameter of the No. 1 thermal oil heater is 1.08m, the height is 2.2m, and the total length of the heating pipe is 385.6m. The heating tubes are φ38×2.5 nickel tubes. The heating tubes are arranged in a hexagonal shape. There are 241 heating tubes in total, and the distance between the tube centers is 57mm.

[0038] The diameter of No. 2 thermal oil heater is 1.3m, the height is 2.6m, and the total length of the heating pipe is 666.06m. The heating tubes are nickel tubes of φ38×2.5, and the heating tubes are arranged in a hexagonal shape. There are 367 heating tubes in total, and the center-to-center distance of the tubes is 57mm.

[0039] The heating pipe is connected with the upper and lower flower boards by the expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com