Pediococcus acidilactici strain and method for producing pediocin by using same

A technology for pediococcus lactis and pediococcus lactis, which is applied in the field of pediocin preparation, and can solve the problems of low yield of pediococcus and low yield of extraction method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

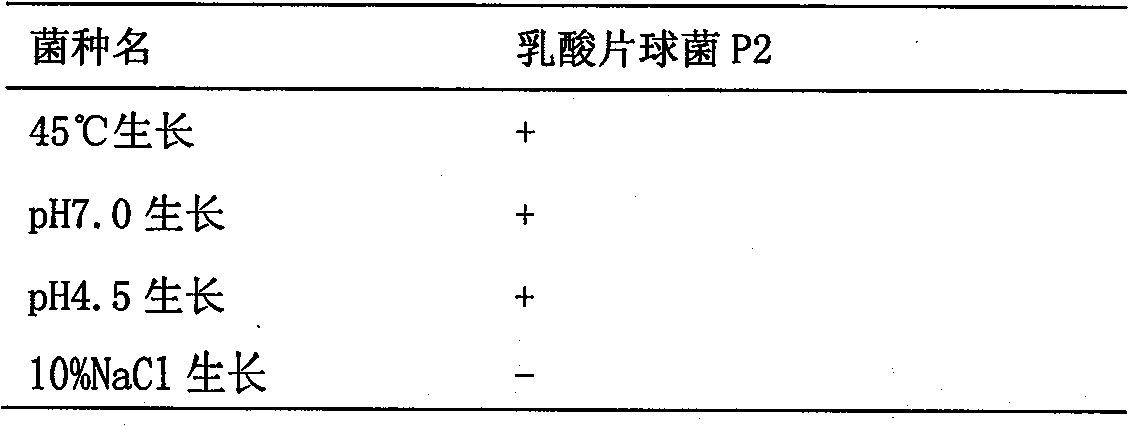

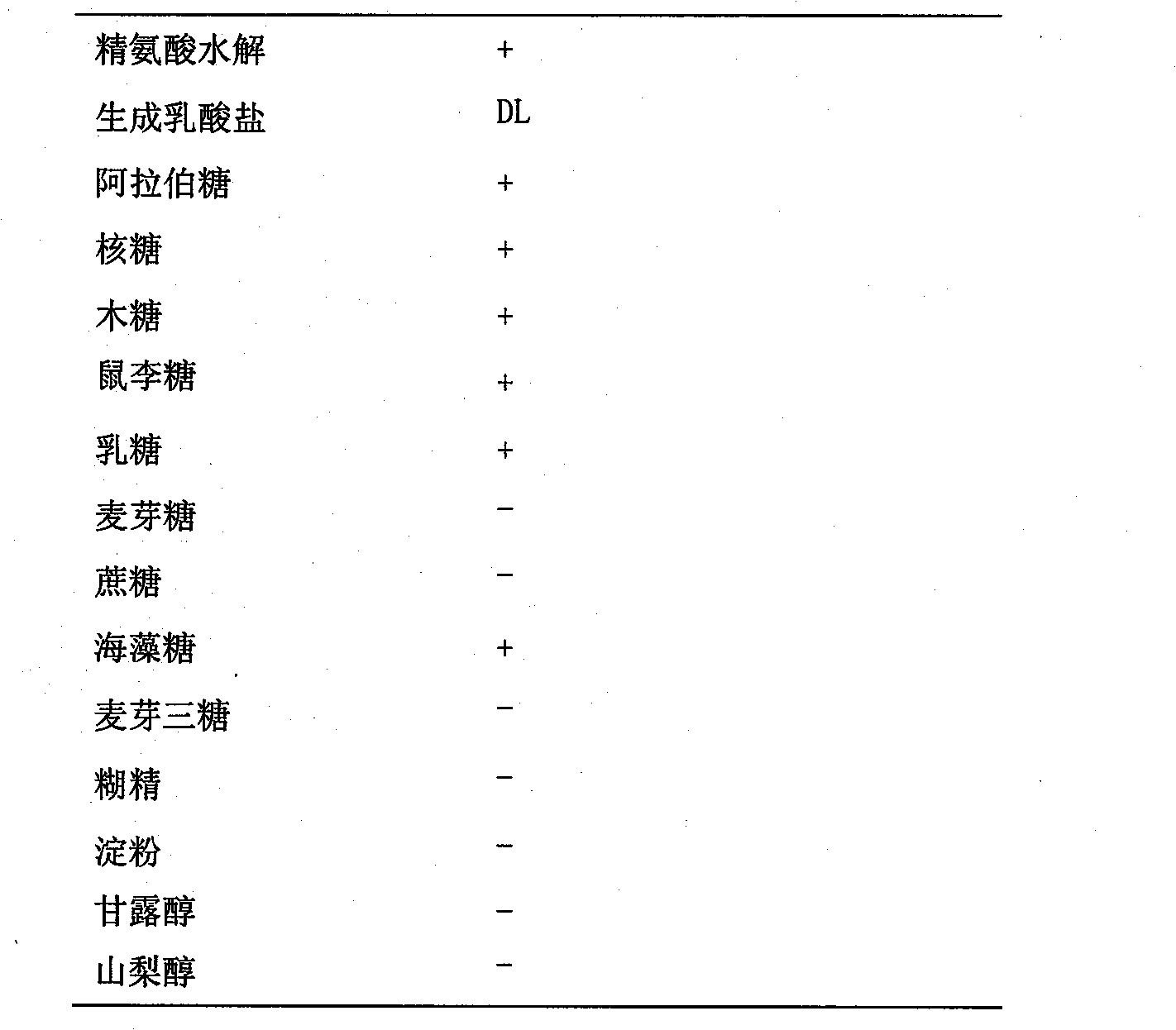

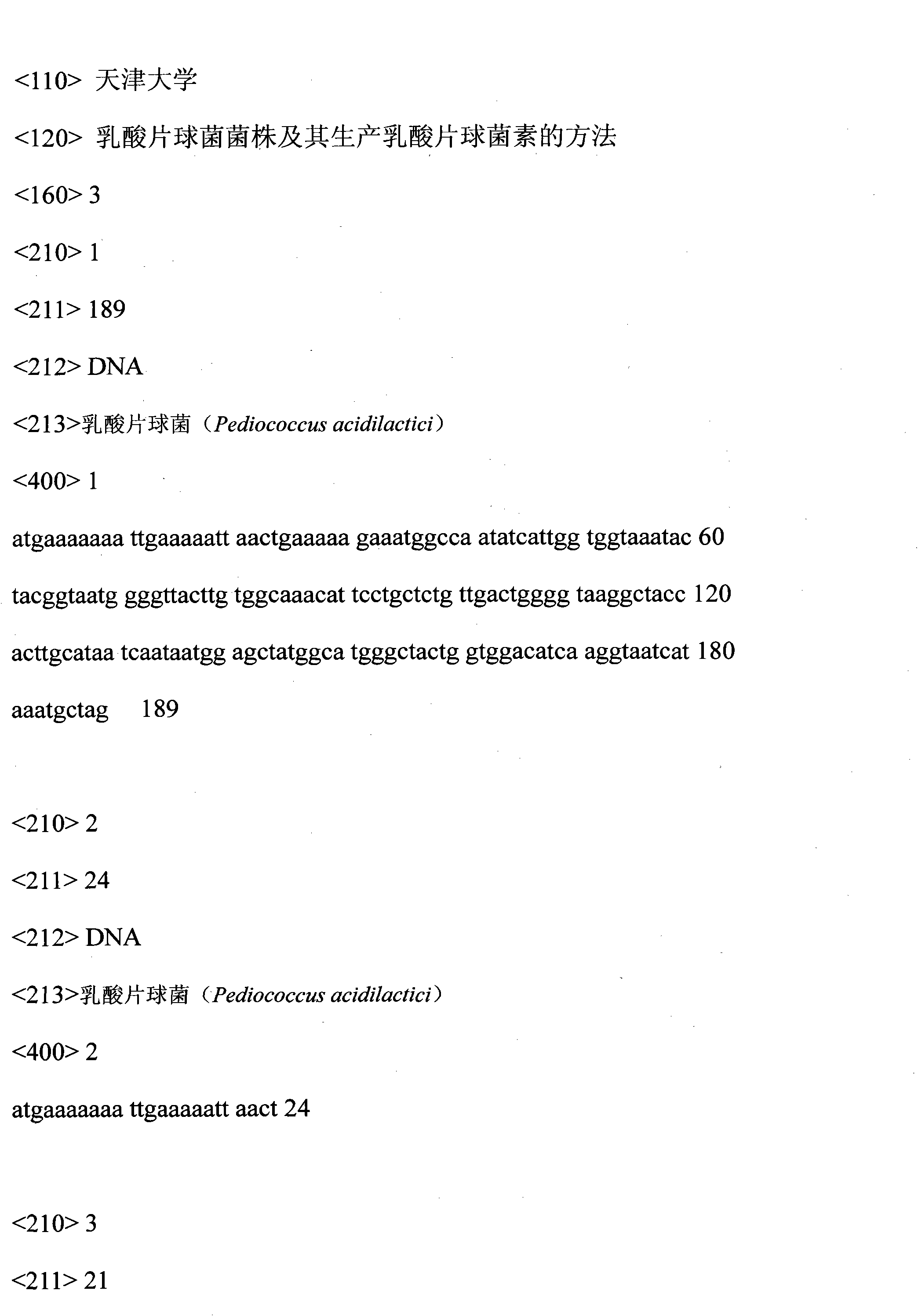

[0050] The mutant strain P2 was obtained by chemical mutagenesis. Orthogonal test was used to determine the mutagenic conditions of DES as follows: Pediococcus liquid concentration is 10 7 cfu / mL, DES concentration was 0.8%, mutagenesis time was 30min, and mutagenesis temperature was 37℃. In the experiment, 20 mutant strains with increased pediocin yield were obtained. The five strains with the largest increase in yield were selected to continue the LiCl mutation breeding experiment, from which five mutant strains with increased yield were further screened, among which the mutant strain P2 had the highest pediocin titer.

[0051] The specific method of mutagenesis is as follows.

[0052] (1) DES chemical mutagenesis method of strain Pediococcus lactis PA003

[0053] ①The effect of single factor on the lethality of strain Pediococcus lactis PA003

[0054] Concentration of bacterial suspension

[0055] The DES concentration is 0.6%, the mutagenesis time is 20min, the mutagenesis tempera...

Embodiment 2

[0075] Isolation of Mutant Strains of Pediococcus lactis

[0076] Pediococin-producing Pediococcus lactis PA003. The yield of Pediococin was 640AU / mL. The strain was mutagenized with DES, and the high-yielding strain was used as the parent strain and then mutagenized with LiCl. After the mutagenesis test, the P2 mutant strain showed the characteristics of high-producing Pediococin, and the performance of Pediococin production remained stable after the strain was passed through the slope for 20 consecutive generations.

[0077] The P2 mutant strain was inoculated into 10 mL of MRS liquid medium and cultured at 37°C for 16 hours. The antibacterial activity in the culture solution was determined by the above agar diffusion method. The yield of the mutant strain P2 was 19.5 times that of the wild strain PA003. The output is 12,480AU / mL.

Embodiment 3

[0079] Medium and fermentation culture method of mutant strain P2

[0080] A single colony of the mutant strain P2 was inoculated into MRS medium, cultured at 37° C. for 16 hours for activation, and then inoculated into the improved MRS medium provided by the present invention for fermentation culture after activation.

[0081] The fermentation culture method is as follows: the activated mutant strain P2 is inoculated into the modified MRS fermentation medium at a rate of 0.5%, the fermentation temperature is 37℃, the dissolved oxygen in the fermentation broth is maintained at 20%, and the glucose is added at a concentration of 0.025g / L after 7 hours of fermentation For every 5 liters of fermentation broth volume, perform intermittent feeding at a flow rate of 2ml / min, and extract pediocin from the fermentation product after 16 hours of cultivation. Using the above method, the yield of Pediococin is 1.77 times that of normal MRS medium and no added glucose for culture and fermentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com