Constant-temperature sonic nozzle process gas flow calibration facility and constant-temperature stagnation vessel

A stagnant container and sonic nozzle technology, applied in the field of gas flowmeter verification and calibration devices, can solve the problems of stagnant container vibration, vibration noise, and high overall power, so as to eliminate the influence of verification and calibration and reduce high-frequency vibration , the effect of reducing working noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

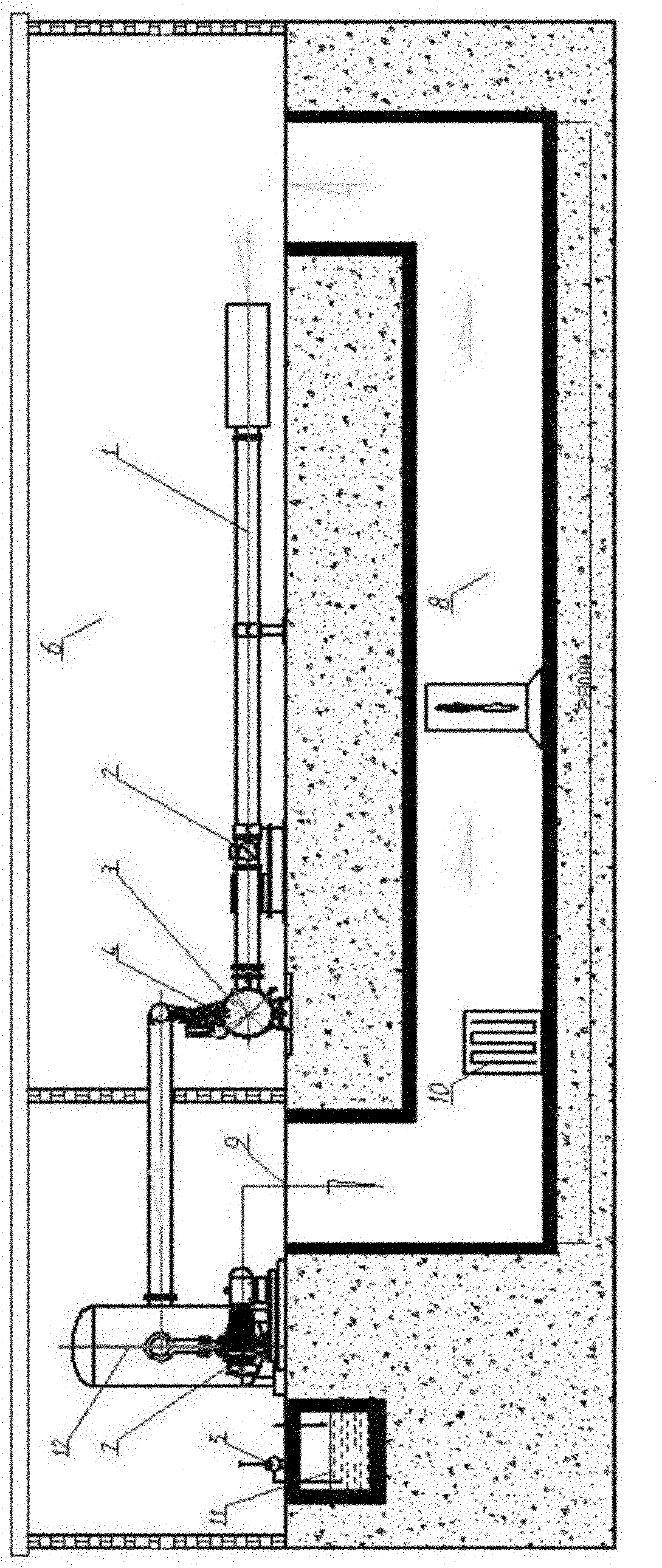

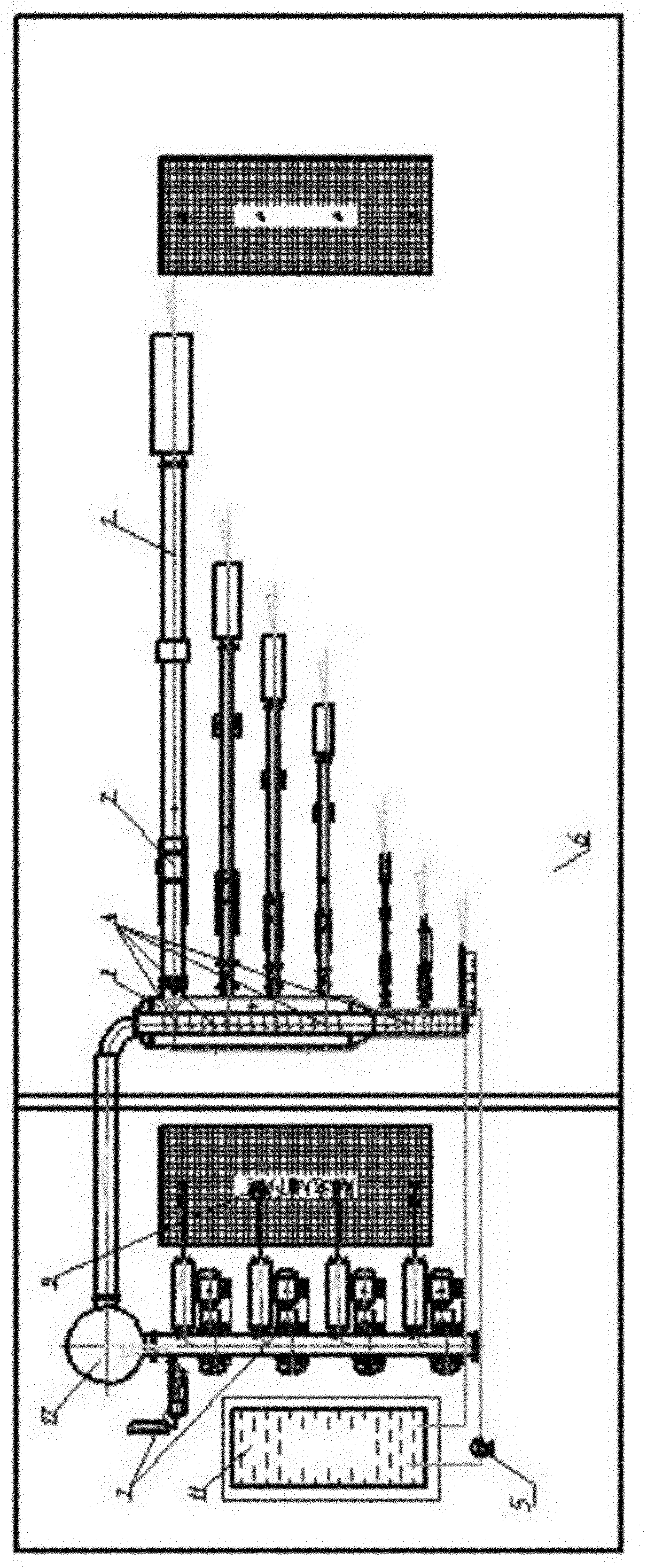

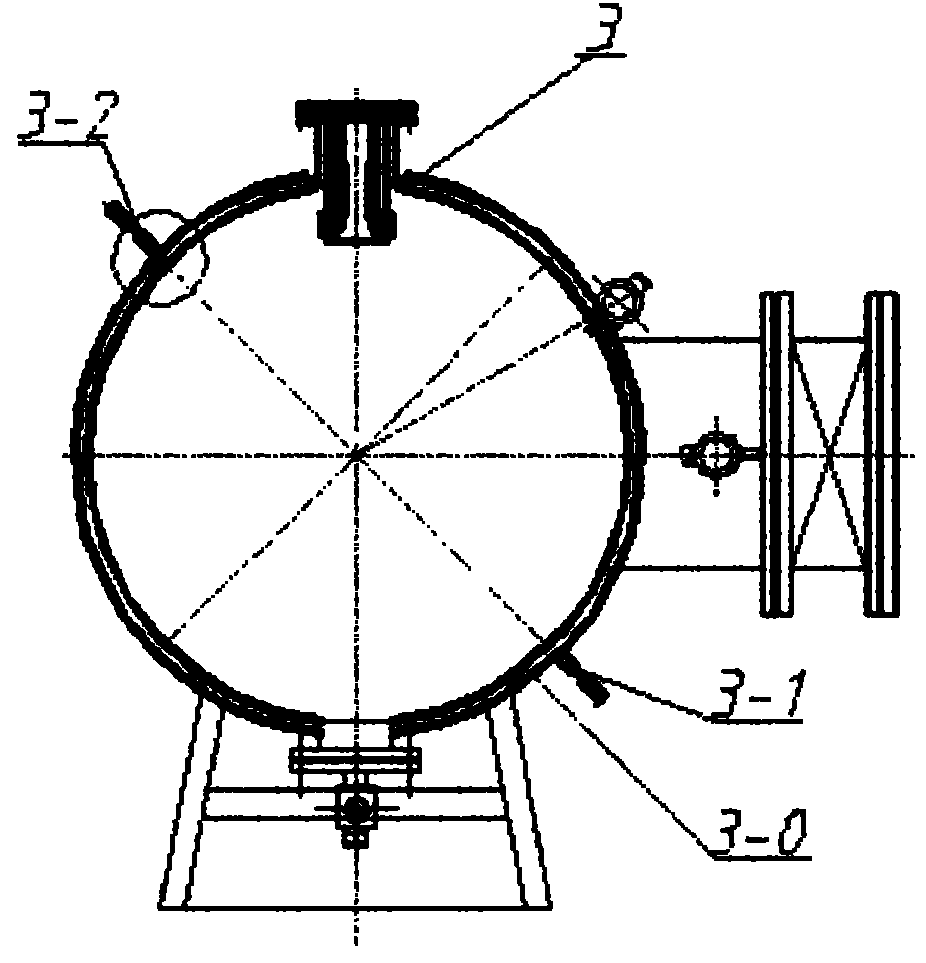

[0014] The constant temperature sonic nozzle method gas flow standard device claimed in the application of the present invention, such as figure 1 As shown, it includes a straight pipeline 1 before the meter connected in sequence, a flow meter 2 to be tested, a stagnation container 3 with a sonic nozzle 4 as a standard meter, and an air source assembly. The air source assembly includes a vacuum pump or an air The press 7, the pressure storage tank 12, the suction and exhaust pipeline and the muffler are composed, wherein the container wall of the stagnation container 3 adopts the water interlayer container wall 3-0, the water inlet pipe 3-1 of the water interlayer type container wall 3-0 and The water outlet pipe 3-2 is connected to the constant temperature water storage body. In the structure of this embodiment, the constant temperature water storage body is a constant temperature pool 11, and a circulating drive water pump 5 is set to form a water circulation channel together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com