Device for measuring specific heat capacity of product

A technology for specific heat capacity and products, which is applied in the field of devices for measuring the specific heat capacity of objects, and can solve the problems of non-negligible, unsuitable specific heat capacity testing of finished products, and long thermal equilibrium time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

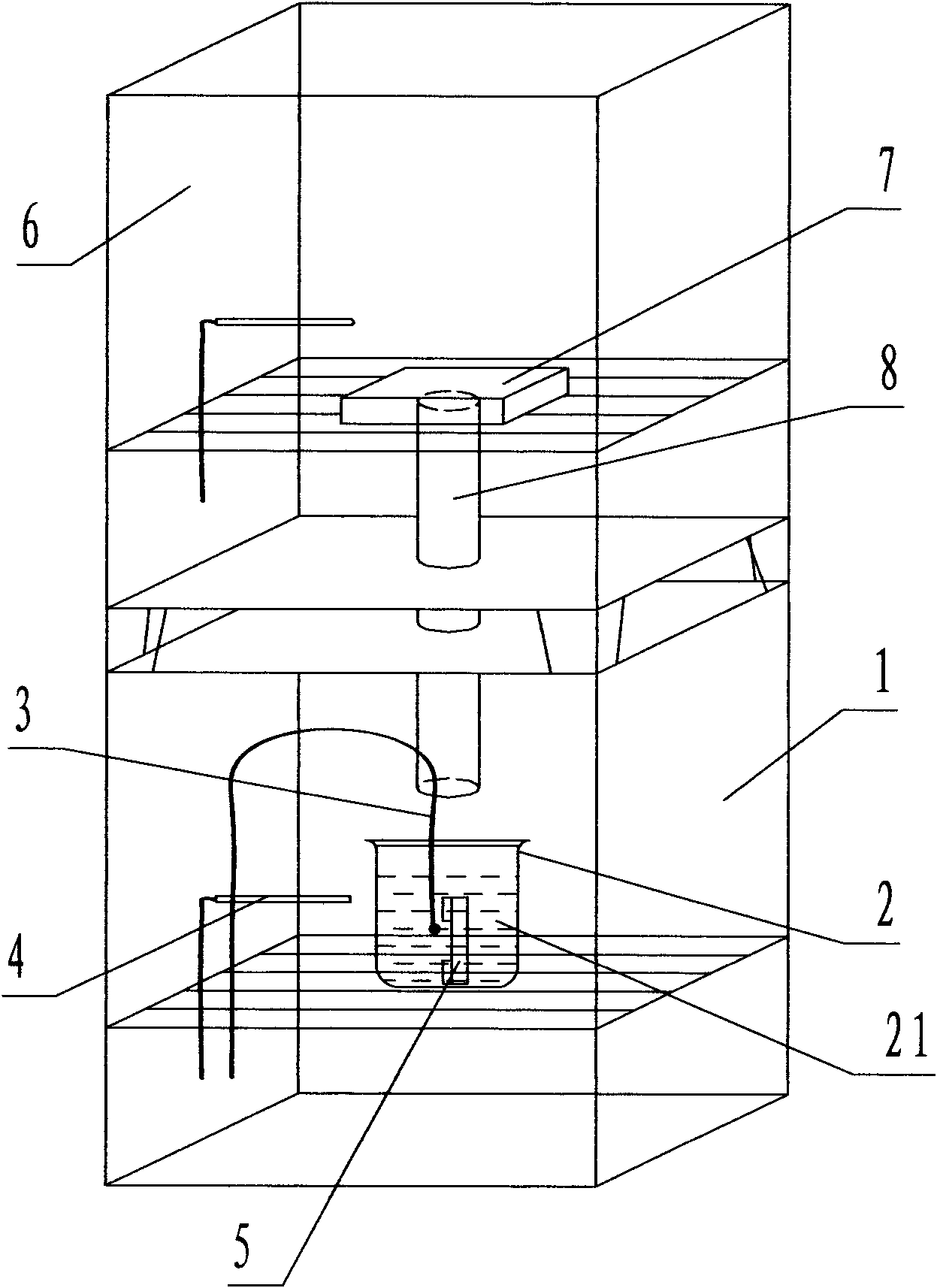

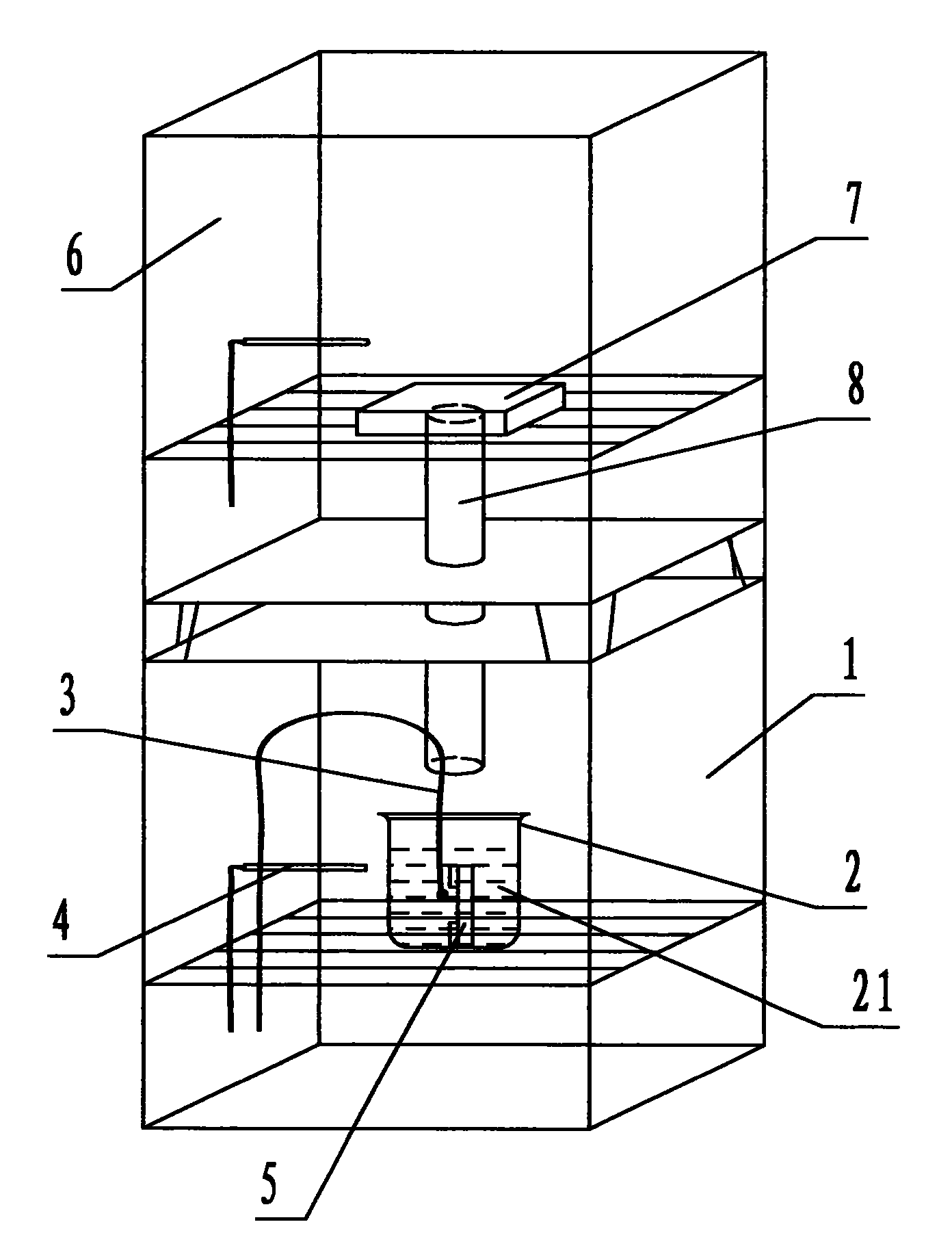

[0028] refer to figure 1 , a device for measuring the specific heat capacity of a product according to the present invention includes a measuring oven 1, a water container 2, medium water 21, a first temperature sensor 3, a second temperature sensor 4, a preheating oven 6, a thermal insulation valve 7, and a connecting channel 8 , wherein: the measurement oven 1 is controlled by a microprocessor, and has an electric heating oven with automatic temperature control, display, and memory functions; The second temperature sensor 4 of resistance and two temperature sensors that are connected with the microprocessor of measuring oven 1 by heat-resistant wire; 4 is used for detecting and feedbacking the air temperature in the measuring oven 1, and placed in the inner space of the measuring oven 1;

[0029] Described water container 2 is a glass beaker, is filled with medium water 21 in the water container 2, and medium water 21 is pure water;

[0030] The water container 2 holds med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com