Acicular silica coating for enhanced hydrophilicity/transmittivity

A silicon dioxide, needle-like technology, used in coatings, other chemical processes, chemical instruments and methods, etc., can solve problems such as difficulty in distinguishing sign information, achieve increased transmittance, good coating durability, dangerous small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0070] Material

[0071] Snowtex from Nissan Chemical Industries (Tokyo, Japan) TM UP is 20-21% by weight of acicular silica, less than 0.35% (w / w) Na 2 O, and water. The particles are about 9 nm to 15 nm in diameter and have a length of 40 nm to 100 nm. The suspension has a viscosity of <100 mPas at 25°C, a pH of about 9 to 10.5, and a specific gravity of about 1.13 at 20°C.

[0072] Snowtex from Nissan Chemical Industries (Tokyo, Japan) TM OUP is 15-16 wt% acicular silica, less than 0.03% (w / w) Na 2 O, and water. The particles are about 9 nm to 15 nm in diameter and have a length of 40 nm to 100 nm. The suspension has a viscosity of <20 mPas at 25°C, a pH of about 2-4, and a specific gravity of about 1.08-1.11 at 20°C.

[0073] Spherical silica nanoparticle dispersion with Nalco 1115 TM (4nm), 2326 TM (5nm), 1030 TM (13nm), and 1050 TM Available from Nalco Corporation (Naperville, IL).

[0074] Tetraethoxysilane (TEOS, 99.9%) is commercially available from Al...

example 1 to 13 and comparative example 1

[0102] In the following Comparative Examples and Examples 1-13, the specified 1% by weight acicular silica particle composition was coated at a pH of 2-3 and a coating thickness of 1 mil (about 25 microns) to on a treated polyethylene terephthalate (PET) substrate and dried at 80-100° C. for 5-10 minutes. For the examples with acicular as well as spherical silica particles, the coating composition was 1% by weight of mixed particles. The coated samples were tested for transmittance, anti-fogging and contact angle using the test methods described previously. Anti-fog performance was determined after one week of exposure to ambient conditions. The results are shown in Table 1. For comparison purposes, uncoated PET samples were also tested.

[0103] Table 1

[0104]

[0105] The results in Table 1 indicate that coatings derived from acicular silica particle coatings generally have better transmittance, anti-fog properties, and contact angle characteristics than coatings ...

example 14-17 and comparative example C5-C7

[0107] In the Examples and Comparative Examples described below, the specified 5% by weight acicular silica particle composition was applied to an untreated poly on a polyethylene phthalate (PET) substrate and dry at 80-120°C for 5-10 minutes. The coated samples were tested for durability (wet and dry rub), coatability and contact angle using the test methods described previously. The results are shown in Table 2. The 100,000X digital micrographs (TEM) of Comparative Example C5 and Example 14 are shown as figure 1 with figure 2 . As can be seen in the figure, figure 1 shows aggregation of silica particles, while figure 2 A much more uniform coating with a much higher degree of bonding between the particles is shown.

[0108] Table 2

[0109]

[0110] The results in Table 2 indicate that dispersions with a pH of less than 5 provided a more uniform coating, while higher pH dispersions beaded or were not coatable.

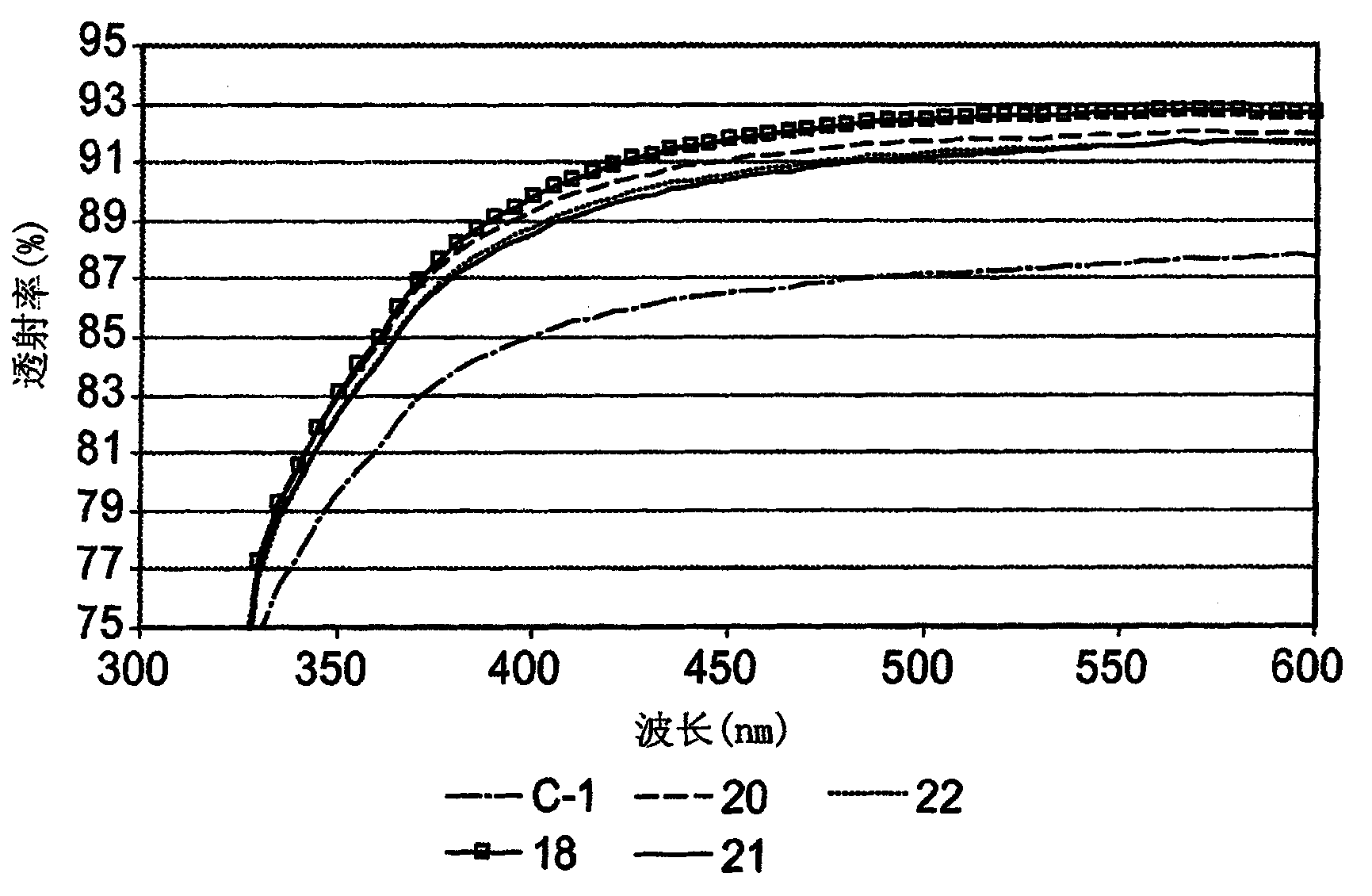

[0111] In Examples 18-33 below, the specified 5% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com