Automotive air conditioning filtering material and preparation method thereof

A technology for filter materials and automobile air conditioners, which is applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor weather resistance, complex processes, and high product costs, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

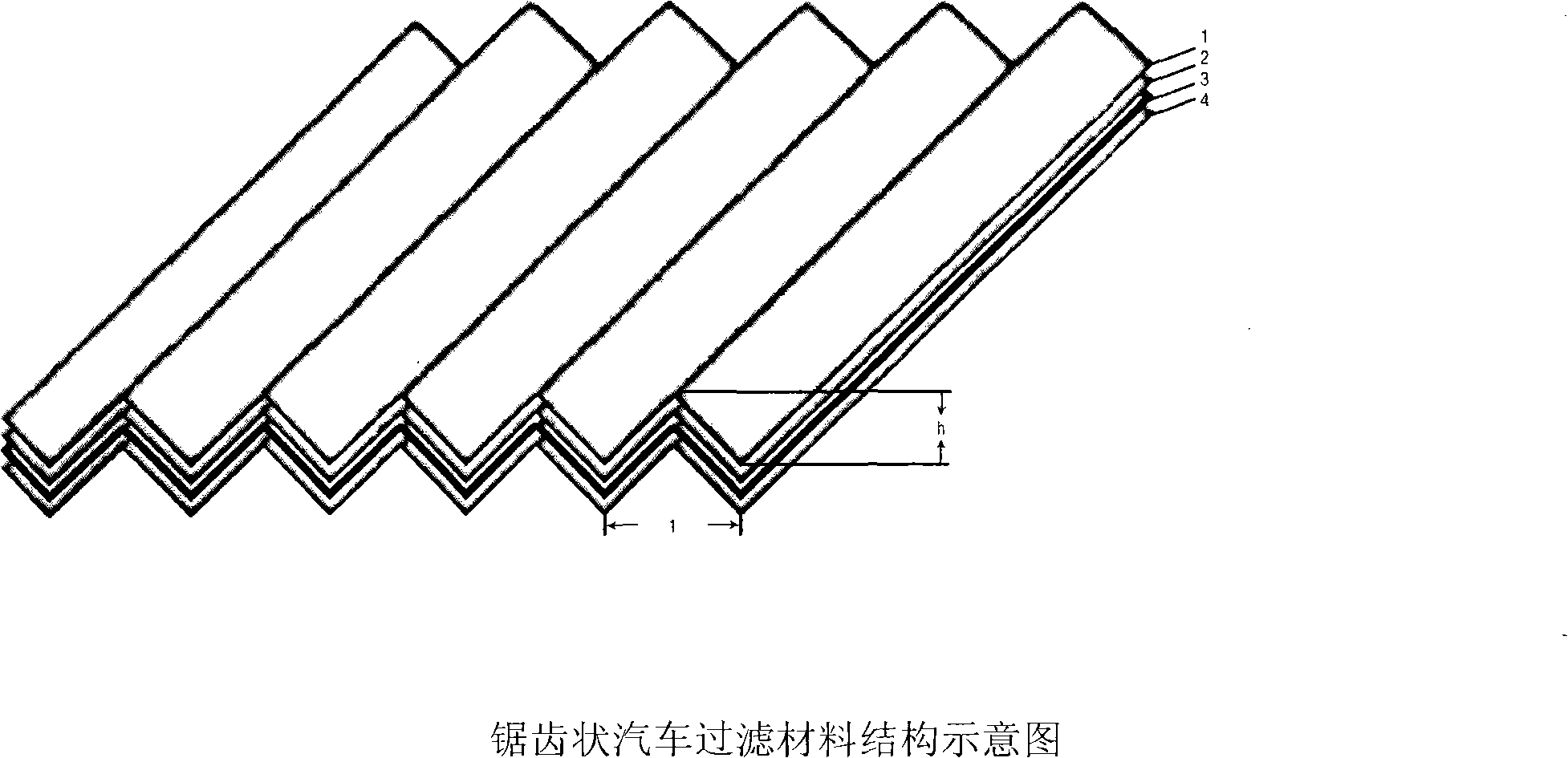

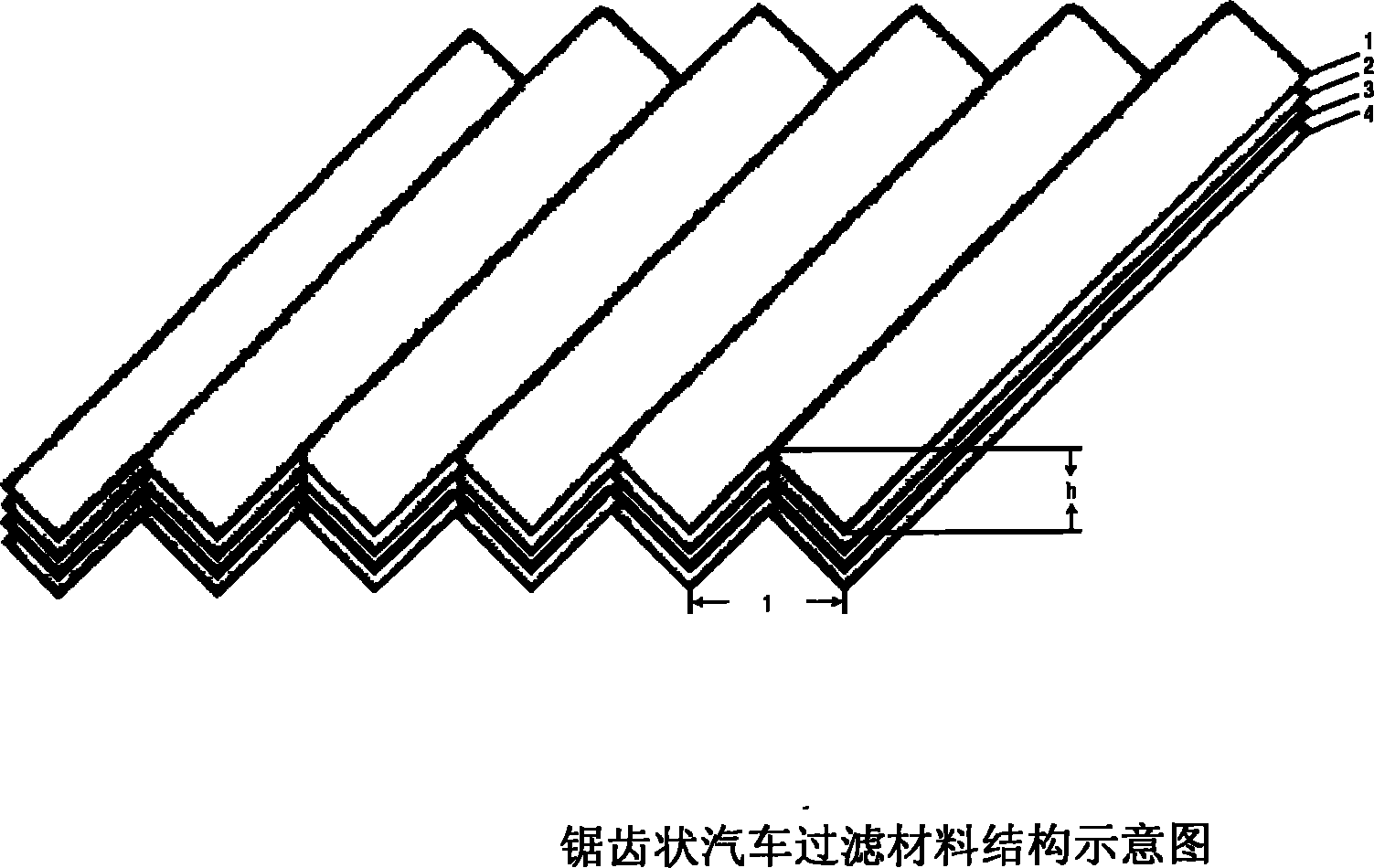

Image

Examples

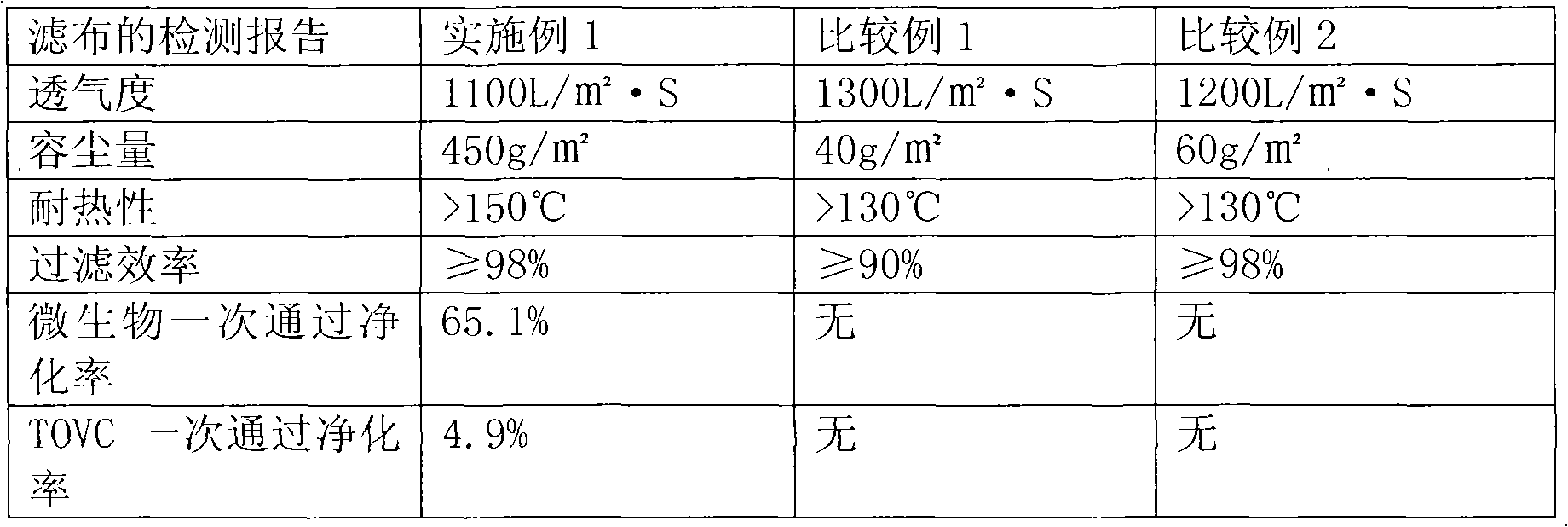

Embodiment 1

[0037] Mix 35% by weight polyester staple fibers and 65% by weight bamboo fiber evenly, and after the mixed fibers are roughly opened and finely opened in turn, the mixed fibers are sent to a carding machine for carding , After the auxiliary installation, the speed of the acupuncture machine is 350 times / min, and the density is 4500 pieces / square meter, so that the polyester staple fiber and the bamboo fiber are evenly mixed into one. When the pre-punched fabric is sent out from the pre-punched machine, spunlace non-woven fabric is laid on the bottom, pp non-woven fabric and melt-blown non-woven fabric are laid on the top; then the compounded fabric is put into the needle punching machine at a speed of 450 times / Minute needle planting, the density is 4500 pieces / square meter; the four layers of materials can be evenly and evenly bonded together; the punctured fabric is sent to the hot roller for contact, the pressure is adjusted to 4 kg / square meter, and the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com