LED fluorescent powder spraying process

A technology of phosphor powder and LED chip, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of color area dispersion, uneven light output, yellow circle, basket circle, etc., to achieve consistency that is easier to control, thickness The effect of uniform, concentrated product color area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

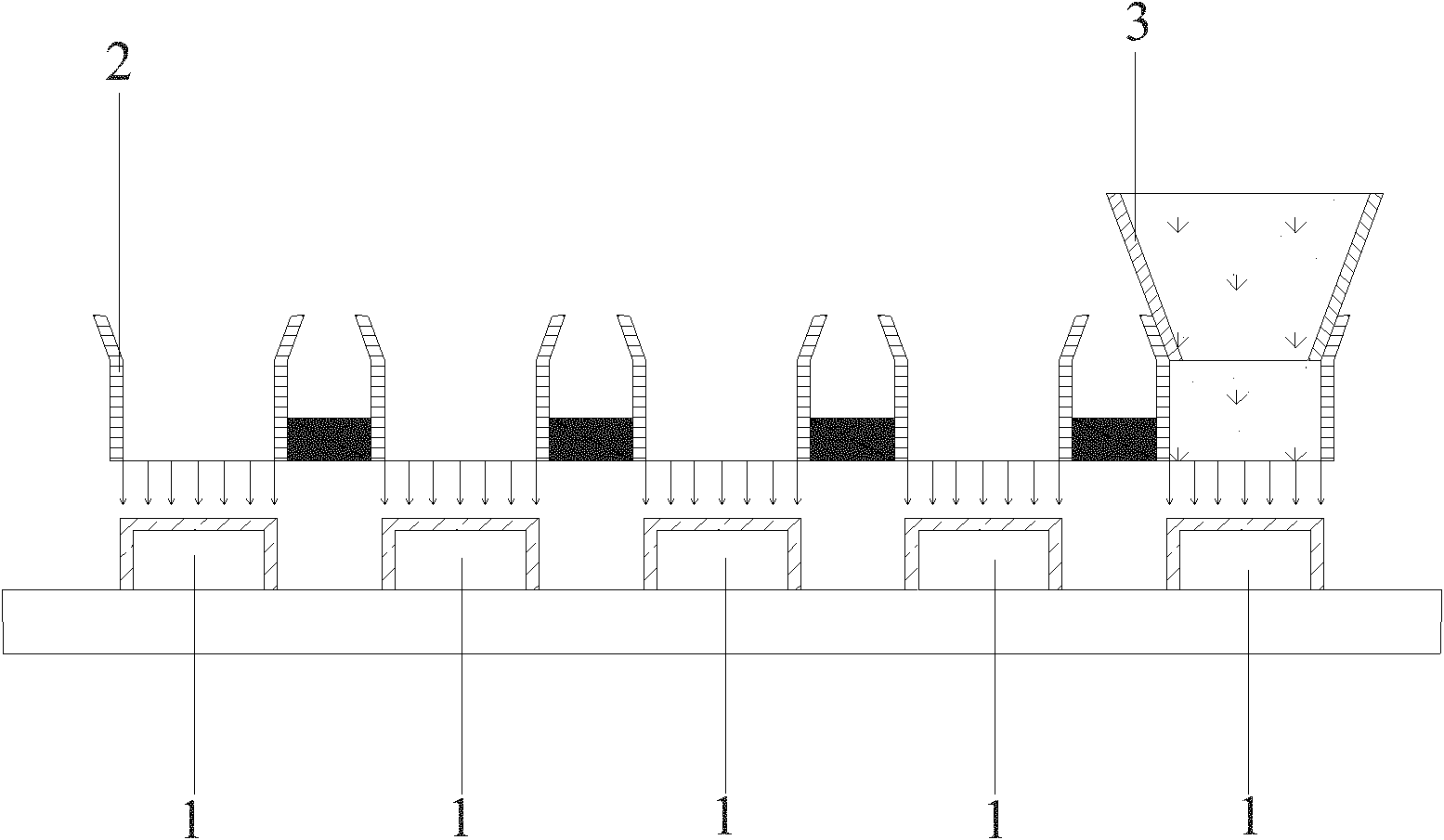

[0017] The LED phosphor spraying process provided in this embodiment includes the following steps:

[0018] (1) Mix the fluorescent powder, adhesive material and volatile solvent evenly to make a mixed liquid of fluorescent powder, and load it in the glue spraying machine; (2) Fix the bracket of the LED chip 1 that has been welded on the fixture; ( 3) Make a mold according to the structure of the LED bracket and the chip 1, the baffle plate 2 of the mold is placed on the top of the LED chip 1, with a certain gap, and the horizontal distance between the baffle plate 2 and the periphery of the LED chip 1 is equal; (4) spray The glue machine 3 sprays the phosphor powder mixture on the surface of the chip 1 through the baffle plate 2, and the baffle plate 2 has played a better role in controlling the directionality of spraying, and the phosphor powder mixture completely surrounds the side and top of the chip 1; ( 5) The heat transferred by the auxiliary heating system of the base ...

Embodiment 2

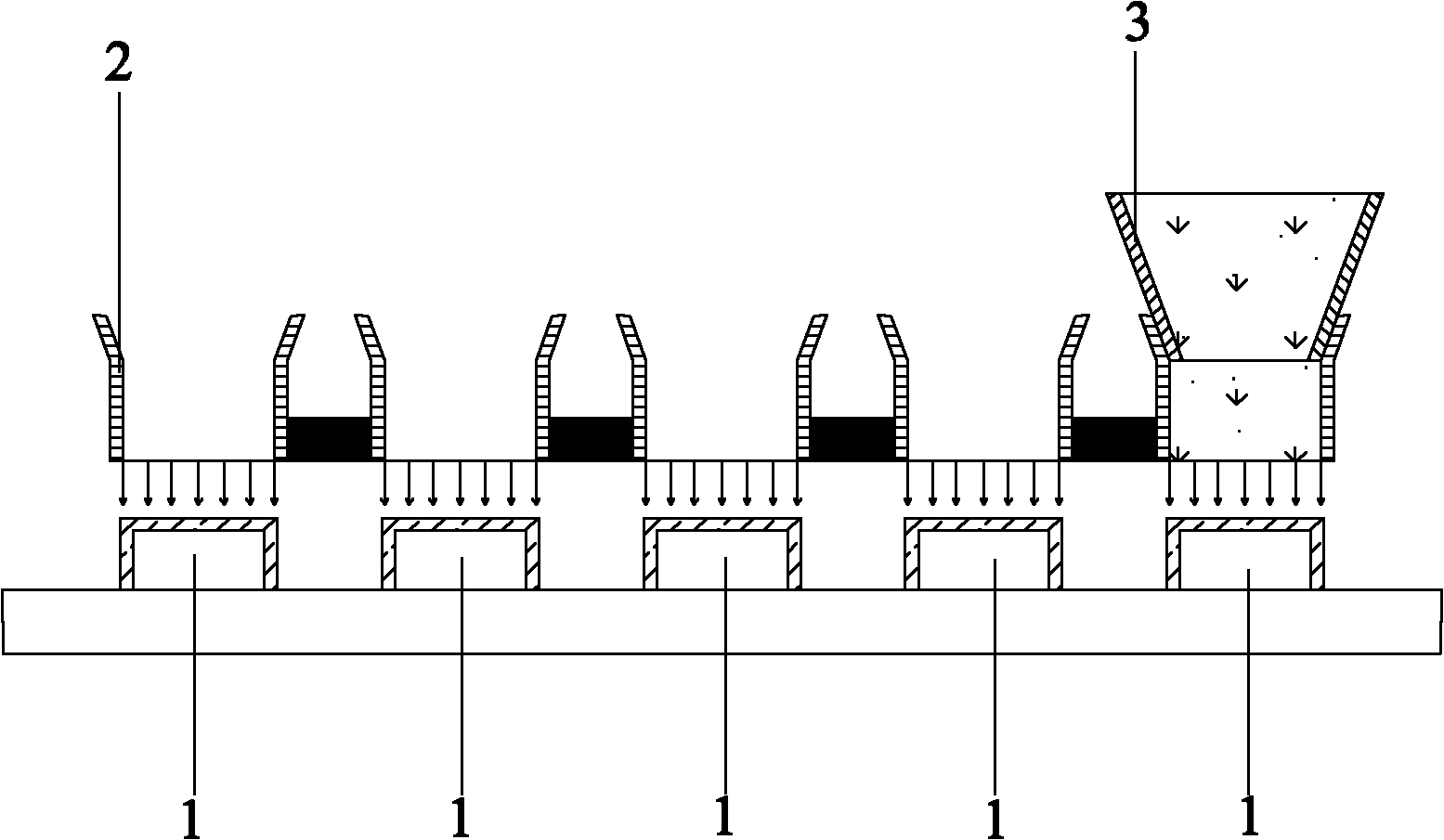

[0020] The LED phosphor spraying process provided in this embodiment includes the following steps:

[0021] (1) Mix the fluorescent powder, adhesive material and volatile solvent evenly to make a mixed liquid of fluorescent powder, and load it in the glue spraying machine; (2) Fix the bracket of the LED chip 1 that has been welded on the fixture; ( 3) Make a mold according to the structure of the LED bracket and the chip 1, the baffle plate 2 of the mold is placed on the top of the LED chip 1, with a certain gap, and the horizontal distance between the baffle plate 2 and the periphery of the LED chip 1 is equal; (4) spray The glue machine 3 sprays the phosphor powder mixture on the surface of the chip 1 through the baffle plate 2, and the baffle plate 2 has played a better role in controlling the directionality of spraying, and the phosphor powder mixture completely surrounds the side and top of the chip 1; ( 5) The heat transferred by the auxiliary heating system of the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com