Method for controlling and treating alumina alkaline waste water from aluminum factory by using acidic smoker waste gas

A technology of acid waste gas and alumina, which is applied in the direction of chemical instruments and methods, separation methods, and the use of liquid separation agents, etc., can solve the problems of large water consumption, high cost, and hindrance to the use of small aluminum plants, and achieve high resource utilization. , reduce emissions, save money and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

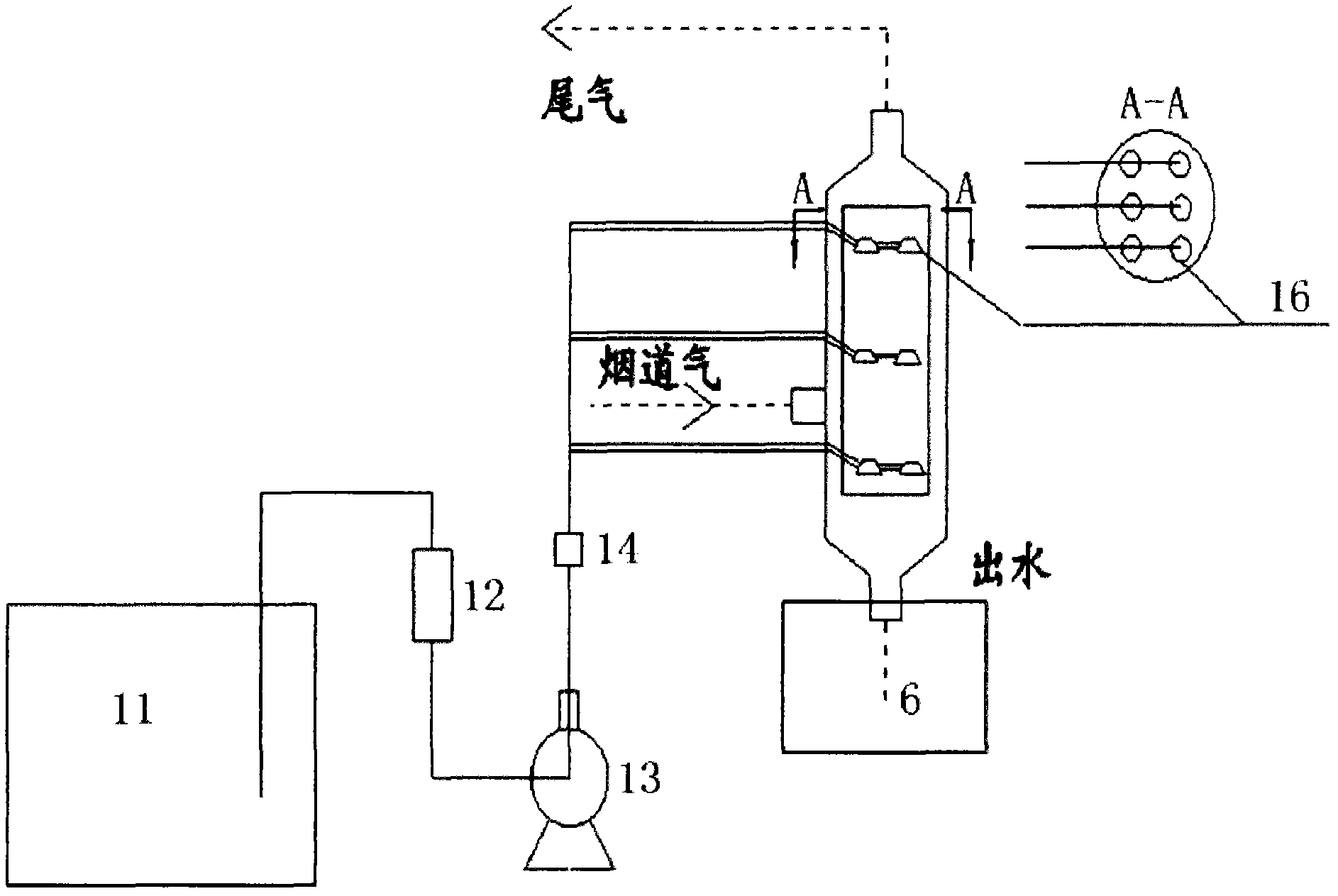

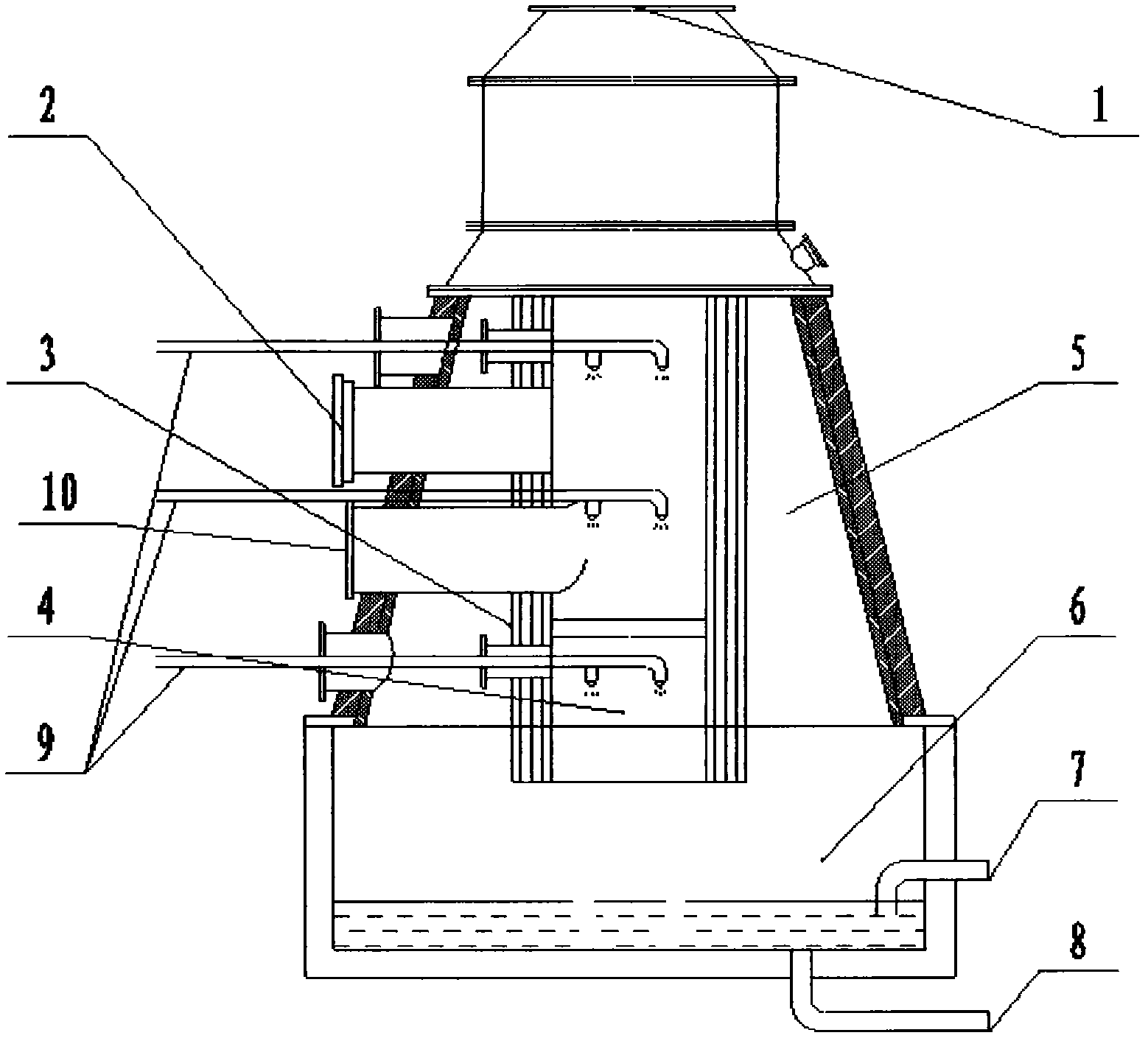

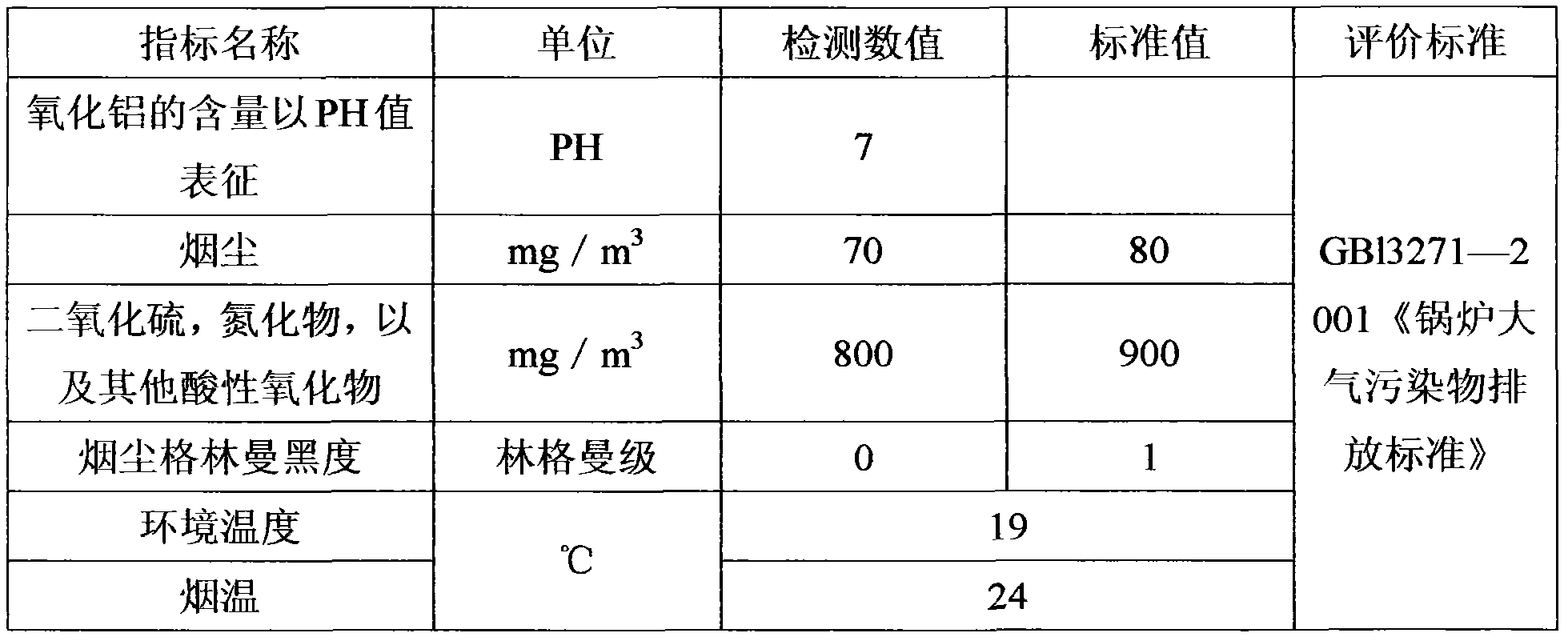

[0017] The equipment for treating alumina alkaline wastewater by using acidic oxides in flue gas includes an alumina alkaline wastewater collection box 11 , a spraying system 9 and a flue dust filtering device 18 .

[0018] The aluminum oxide alkaline waste water collection box 11 is made of stainless steel, with a volume of 15 cubic meters and a thickness of 5 millimeters.

[0019] The spray system 9 includes a filter screen 12, a booster pump 13, a solenoid valve 14, a nozzle 16 and a spray pipeline. The working process of the spray system 9 is as follows. After the booster pump 13 works, the alumina alkaline wastewater enters the booster pump 13 through the filter screen 12, and the booster pump 13 increases the pressure to about 1 MPa, and the spray pipeline passes through the solenoid valve 14, Finally, it is sprayed out by the nozzle 16.

[0020] The smoke and dust exhaust gas filtering device 18 includes a smoke and dust exhaust gas inlet 10, a smoke and dust exhaust g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com