Equipment for treating H-acid production wastewater

A technology for producing wastewater and treating equipment, applied in the field of H-acid production wastewater treatment equipment, can solve the problems of polluted environment, complicated operation, high toxicity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

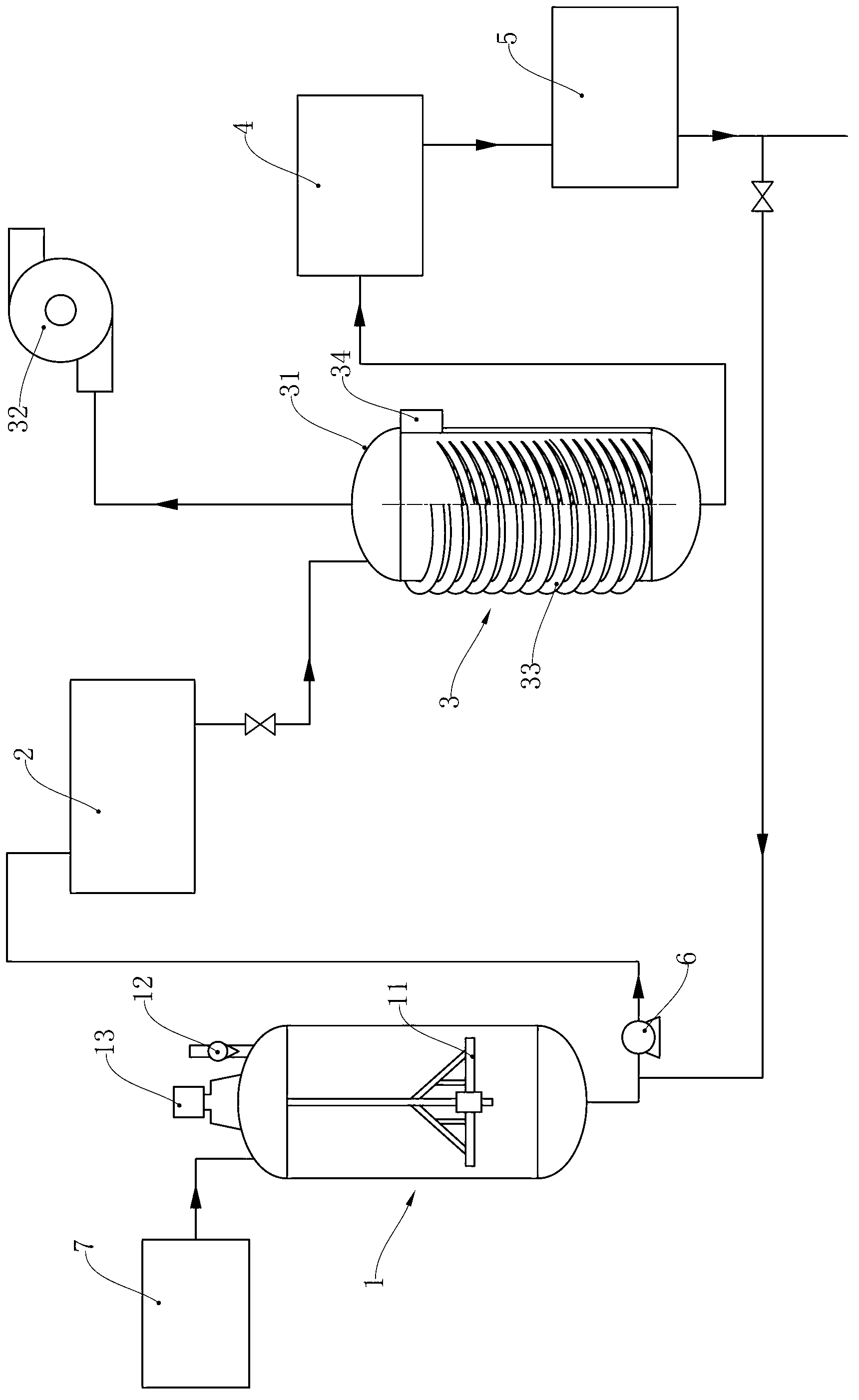

[0046] H-acid production wastewater treatment method, comprises the steps:

[0047] S1. Pour the H-acid waste liquid into the neutralization pot 1, start stirring, control the rotating speed of the stirring paddle 11 at 23 rpm, add ammonia water at a uniform speed, and constantly use pH test paper to detect the feed liquid during the addition of ammonia water to prevent Excessive ammonia water is added to finally obtain a rough treatment feed liquid with a pH value of 4, and the rough treatment feed liquid is pumped into the head tank 2 by the transfer pump 6 for use;

[0048] S2. Add the crude treatment feed liquid obtained in step S1 from the head tank 2 to the evaporating pot 3, control the liquid level in the still body 31 to be higher than the internal heating steam coil 33 by about 15 cm, and open the inside and outside of the still body 31 at the same time Heating the steam coil 33, when the temperature rises to 90°C, turn on the decompression blower 32, control the pre...

Embodiment 2

[0053] H-acid production wastewater treatment method, comprises the steps:

[0054] S1. Pour the H-acid waste liquid into the neutralization pot 1, start stirring, control the rotating speed of the stirring paddle 11 at 20 rpm, add ammonia water at a uniform speed, and constantly use pH test paper to detect the feed liquid during the addition of ammonia water to prevent Excessive ammonia water is added to finally obtain a rough treatment feed liquid with a pH value of 4, and the rough treatment feed liquid is pumped into the head tank 2 by the transfer pump 6 for use;

[0055] S2. Add the crude treatment feed liquid obtained in step S1 from the head tank 2 to the evaporating pot 3, control the liquid level in the still body 31 to be higher than the internal heating steam coil 33 by about 15 cm, and open the inside and outside of the still body 31 at the same time Heating the steam coil 33, when the temperature rises to 85°C, turn on the decompression blower 32, control the pre...

Embodiment 3

[0060] H-acid production wastewater treatment method, comprises the steps:

[0061] S1. Pour the H-acid waste liquid into the neutralization pot 1, start stirring, control the rotating speed of the stirring paddle 11 at 25 rpm, add ammonia water at a uniform speed, and constantly use pH test paper to detect the feed liquid during the addition of ammonia water to prevent Excessive ammonia water is added to finally obtain a rough treatment feed liquid with a pH value of 5, and the rough treatment feed liquid is pumped into the head tank 2 by the transfer pump 6 for use;

[0062] S2. Add the crude treatment feed liquid obtained in step S1 from the head tank 2 to the evaporating pot 3, control the liquid level in the still body 31 to be higher than the internal heating steam coil 33 by about 15 cm, and open the inside and outside of the still body 31 at the same time Heating the steam coil 33, when the temperature rises to 95°C, turn on the decompression blower 32, control the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com