High-air-permeability paper pulp and preparation method and application thereof

An air permeability and pulp technology, applied in papermaking, textile and papermaking, cellulose raw material pulping, etc., can solve the problems of air permeability fiber shape broken, poor air permeability, low air permeability, etc., and achieve good water absorption and air permeability. The effect of improved performance, reduced packing pressure and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

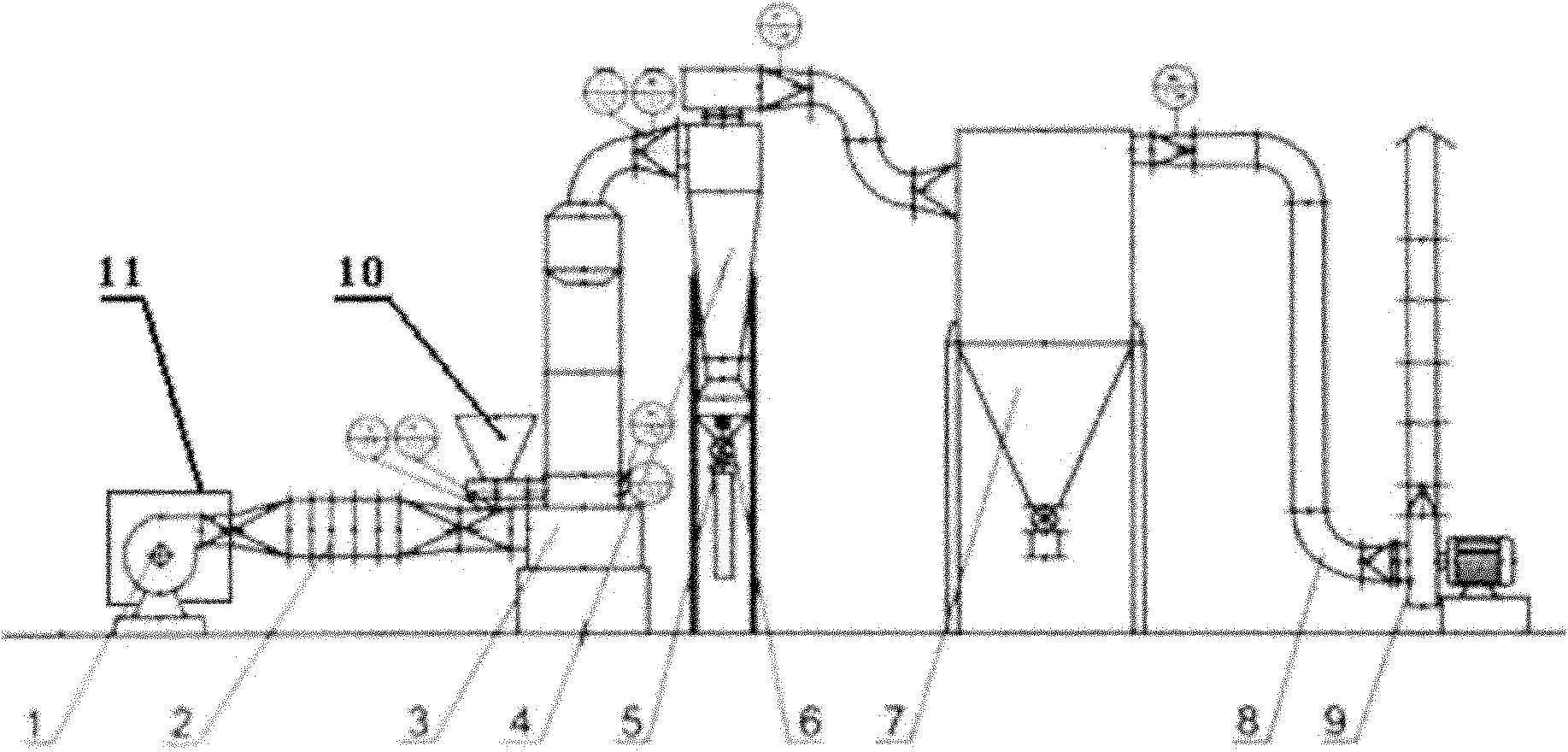

Method used

Image

Examples

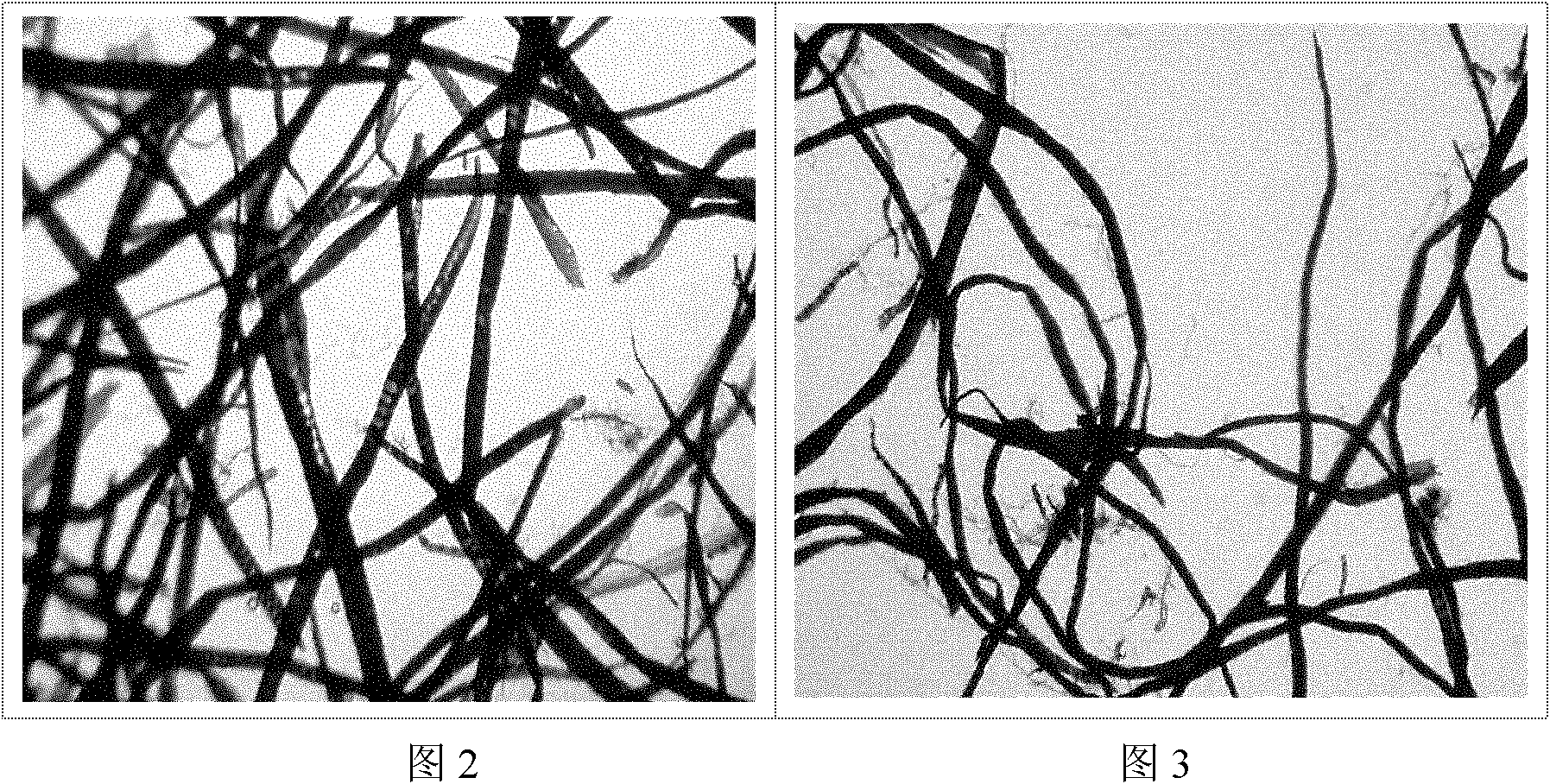

Embodiment 1

[0051] Ordinary pulp raw materials: flat or roll-shaped bleached softwood pulp board (moisture ≤ 20%).

[0052] 1. Decompose the raw material dry pulp board with clear water first, the pulp concentration is 4.0wt%, the water temperature is 35°C, and the decompression time is 0.5 hours; a hydraulic pulper (2JGS energy-saving hydraulic pulper, Zhucheng Jinlong Machinery Manufacturing Co., Ltd.) is pulped deal with.

[0053] 2, the slurry that step 1 obtains utilizes rotor sieve (model XY-1-3, Zhucheng Wanfang Machinery Co., Ltd.) to sieve the fibers, and the broken small fibers with fiber length≤0.8mm are screened out, and the Slurry concentration 0.08-0.50%, normal temperature, normal pressure.

[0054] 3. Dry the slurry obtained in step 2 with air flow, the moisture content of the slurry before drying is 50%, and the slurry before drying is preheated to a temperature of 50°C; then it is sent to the airflow dryer, and the air pressure of the airflow fan is 4.0-5.0 kg / cm 2 , ...

Embodiment 2

[0059] Ordinary pulp raw material: loose (moisture 20-40%) bleached softwood pulp.

[0060] 1. Dilute the loose pulp raw material with clean water to a pulp concentration of 3.8wt%, and the water temperature is 30-35°C, and then deflagged by a deflagging machine for 30 minutes.

[0061] 2. Sieve the slurry obtained in step 1, and screen out the broken small fibers with a fiber length≤0.8mm, the screening concentration is 0.15wt%, and other conditions are the same as in Example 1.

[0062] 3. Dry the slurry obtained in step 2 with air flow, the moisture content of the slurry before drying is 55%, and the slurry before drying is preheated to a temperature of 60°C; then it is sent into an airflow dryer, and the air pressure of the fan is 4.5kg / cm2 , dried by hot air flow to 90% pulp dryness.

[0063] 4. Cool the dry hot slurry obtained in step 3, and control the temperature of the air of the cooling fan at 30-32°C.

[0064] 5. Pack the dried pulp obtained in step 4. The tempera...

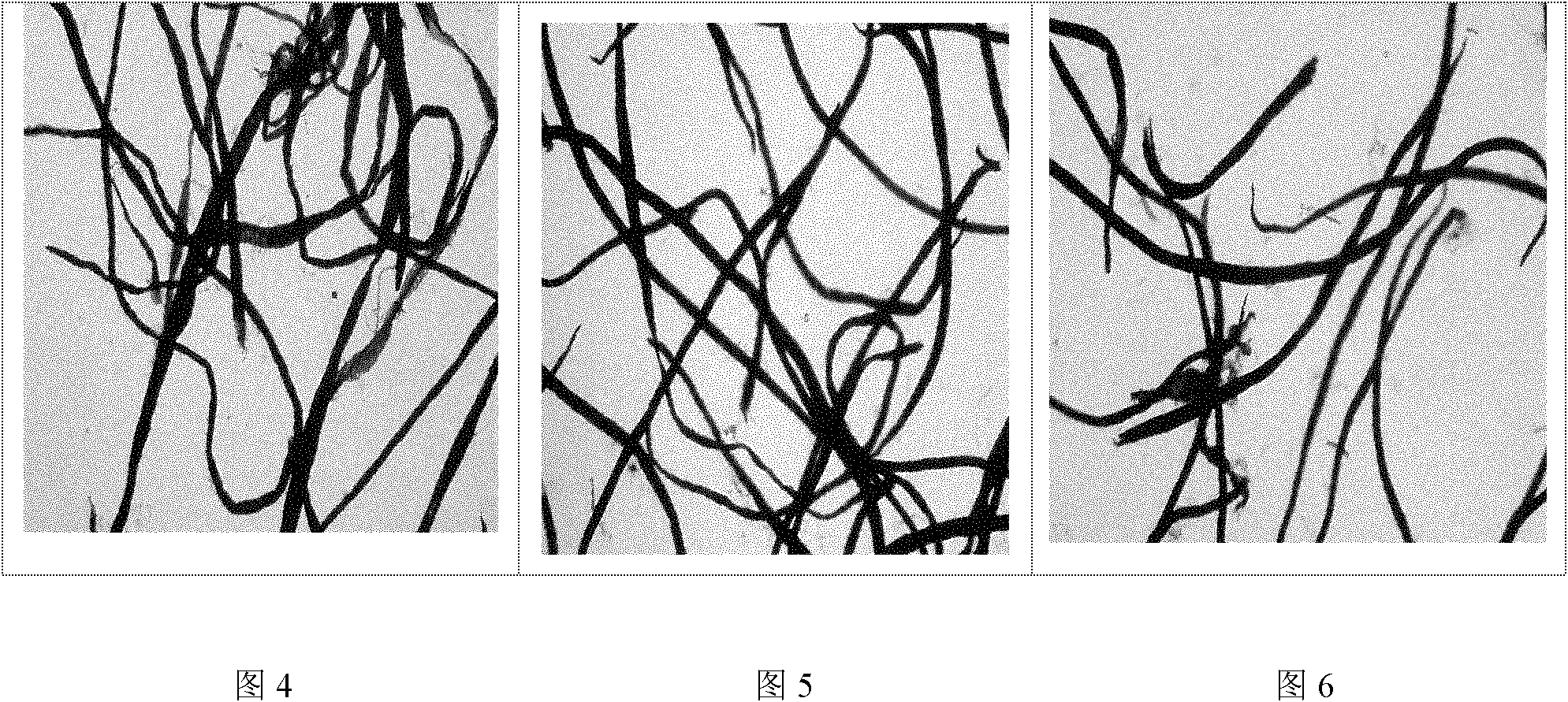

Embodiment 3

[0066] Embodiment 3: Ordinary pulp raw material: wet bleached softwood pulp (moisture greater than 60%).

[0067] 1. Dilute the wet slurry raw material directly with water in the slurry tank to a slurry concentration of 3.5wt%, and the water temperature is 25-30°C

[0068] 2, the slurry that step 1 obtains is screened, with embodiment 1.

[0069] 3, the slurry that step 2 obtains is carried out air flow drying, with embodiment 1.

[0070] 4. Cool the slurry obtained in step 3, and control the temperature of the cooling fan at 20-25°C.

[0071] 5. Pack the dried pulp obtained in step 4. The temperature of the pulp before packing is 20-25°C, the packing pressure is 50-90MPa, and the pulp tightness is 0.5g / cm 3 .

[0072] The micrograph of the obtained product pulp is as Image 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tightness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com