Redundancy architecture control system and method thereof capable of keeping original system function and performance

A technology of control system and original system, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of large influence on production progress, and achieve the effect of improving production efficiency, flexible structure and perfect function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

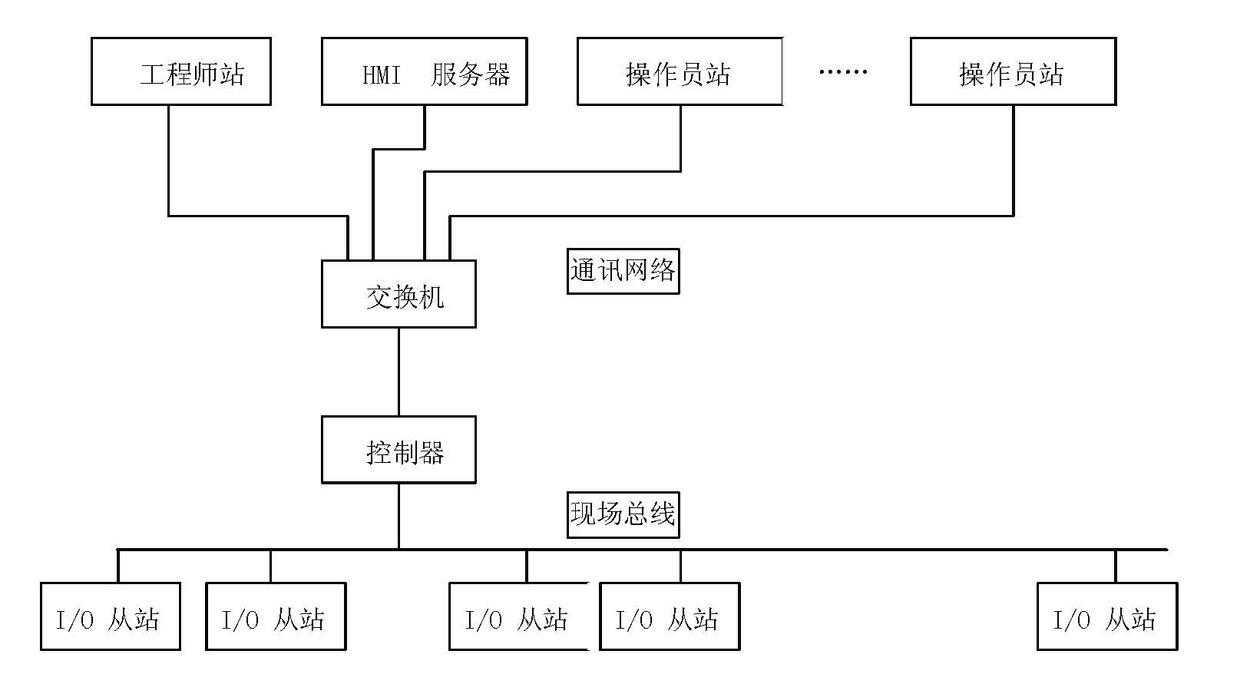

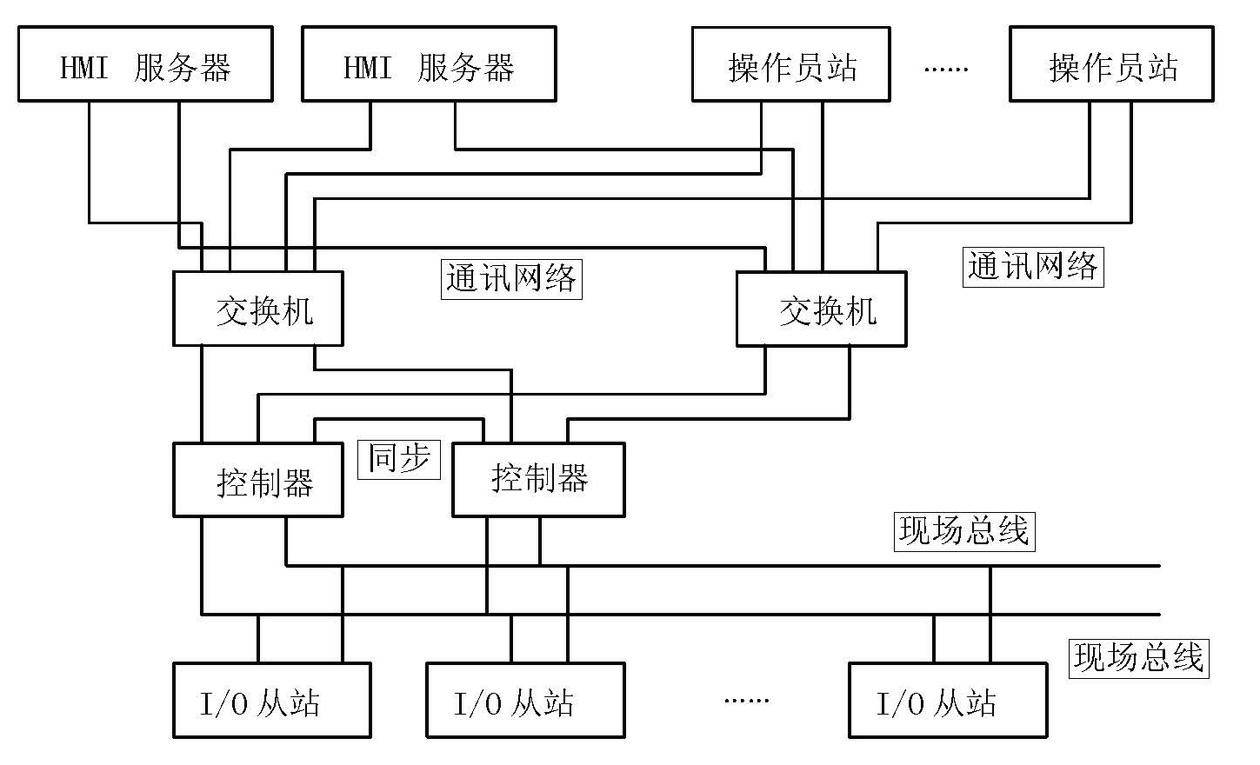

[0067] The existing automatic control platform in metallurgical automation engineering is applied in various fields of metallurgical industry, has excellent performance and reliable operation, and is already very mature. Its basic components are as follows: figure 1 shown. The system has multiple operator stations and HMI servers. These stations are connected to the controller through the communication network and switches in the communication network. The controller is connected to multiple I / O slave stations through the field bus. in:

[0068] Control station: It is used for process control and realizes hardware devices with relatively dispersed physical location and control functions. In the control station, the high-performance microprocessor is used as the core to perform various process control operations and digital logic operations, and can exchange information with each I / O slave station through the field bus, that is, to obtain the field data collected by the I / O sl...

Embodiment 2

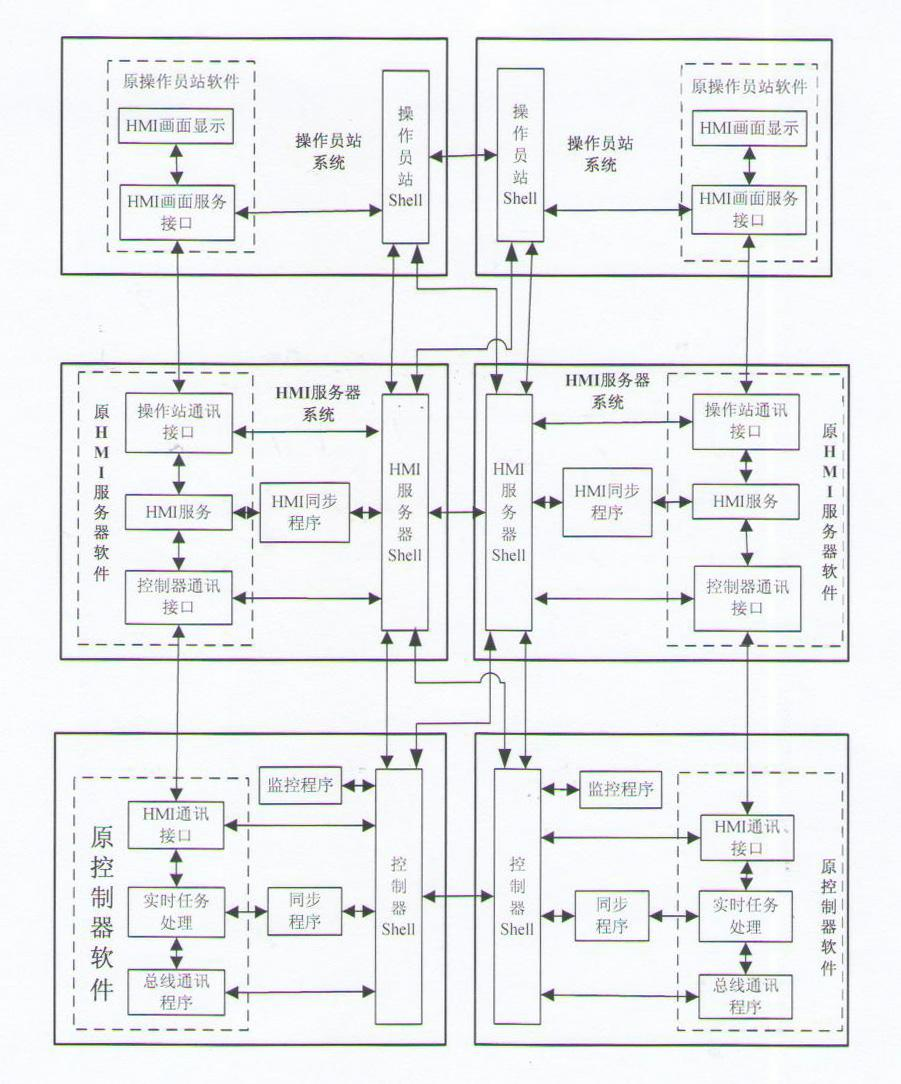

[0090] This embodiment is a redundant architecture control method that uses the system described in Embodiment 1 to maintain the original system function and performance. The startup and operation steps of each site are as follows:

[0091] a. Controller startup and operation steps:

[0092] 1) Startup steps:

[0093] Start the real-time Linux operating system: load the real-time Kernel and file system, and run all device drivers.

[0094] Controller Shell program startup: establish a communication channel with another controller and two HMI servers for the fieldbus communication program, monitoring program, synchronization program, HMI communication program, etc. of this controller.

[0095] Load the fieldbus driver to complete the establishment of fieldbus communication.

[0096] The monitoring program starts, ready to monitor each application in real time.

[0097] Start the real-time task processing program: start to perform control algorithm calculation in real time a...

Embodiment 3

[0130] This embodiment is an improvement of the second embodiment, and is a refinement of the monitoring program described in the second embodiment. The monitoring program is to comprehensively manage the site status management and command management of the entire redundant control platform, and the human-computer interaction interface of the monitoring program is set in an operator station. This operator station becomes an engineer station through software setting. The engineer station has supervisory authority and displays some management-related information, and the others are exactly the same as the operator station. Therefore, the operation of the monitoring program should set an operator station as an engineer station. The process steps of monitoring program operation are as follows:

[0131] a. Check the status of the controller, HMI server and I / O slave station, including master, slave, stand-alone operation, and fault status, and update these statuses to the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com