Negative temperature coefficient thermal resistor with variable thermosensitive index

A technology of negative temperature coefficient and thermistor, which is applied to resistors with negative temperature coefficient, etc., can solve problems such as difficulty in controlling measurement accuracy, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described below in combination with specific embodiments and with reference to the accompanying drawings.

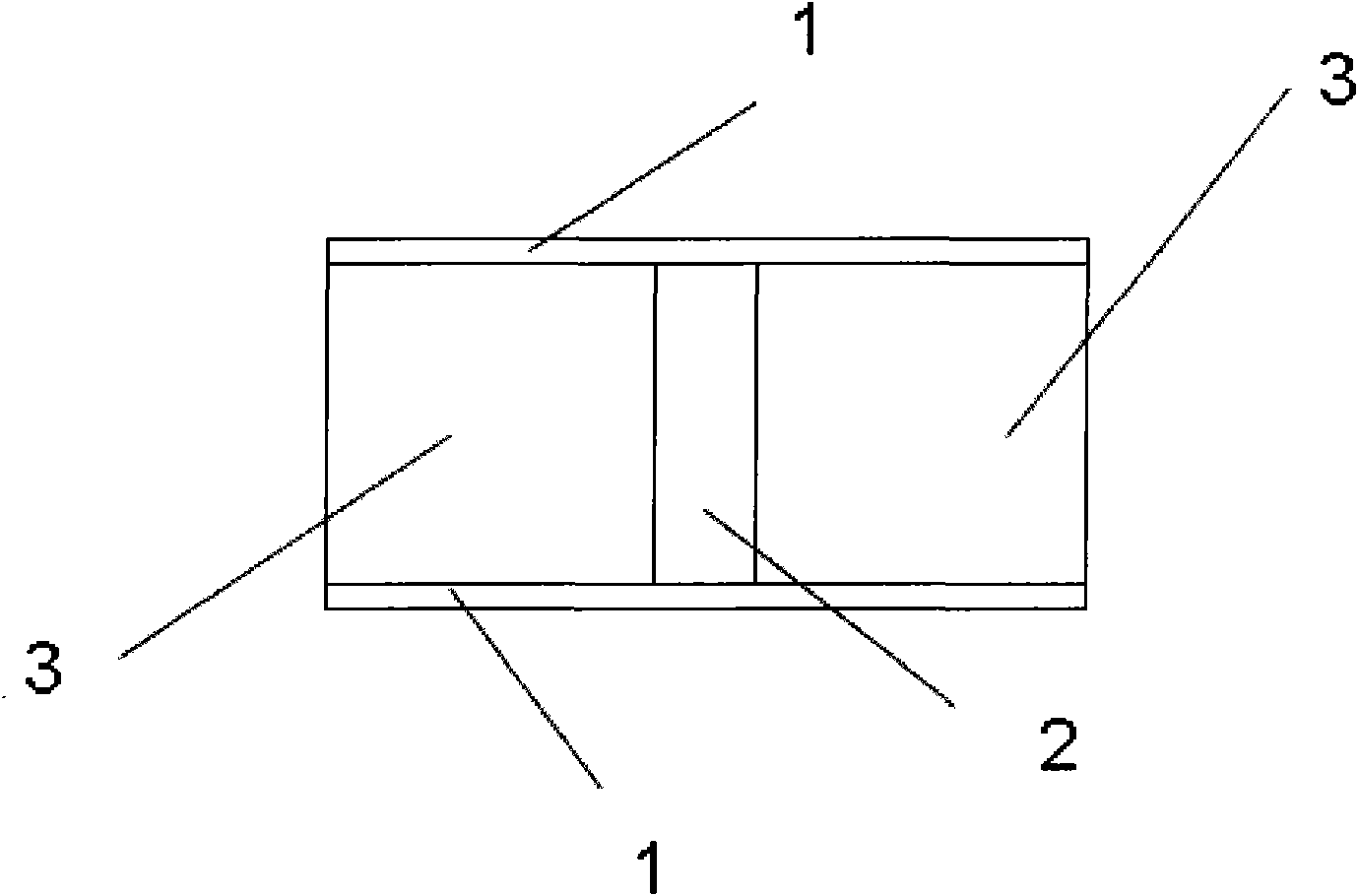

[0037] a kind of like figure 1 , 2 The shown variable thermal index thermistor with negative temperature coefficient includes a thermistor chip. The parallel upper and lower surfaces of the thermistor chip are respectively provided with parallel upper and lower metal pole pieces. The metal pole pieces are respectively welded with parallel upper and lower electrode pieces. The thermistor chip is formed by lamination roasting of green embryo diaphragms and rolling extrusion. The green embryo diaphragms are formed by slurry flow including transition metal oxide mixed powder. Delay and drying molding.

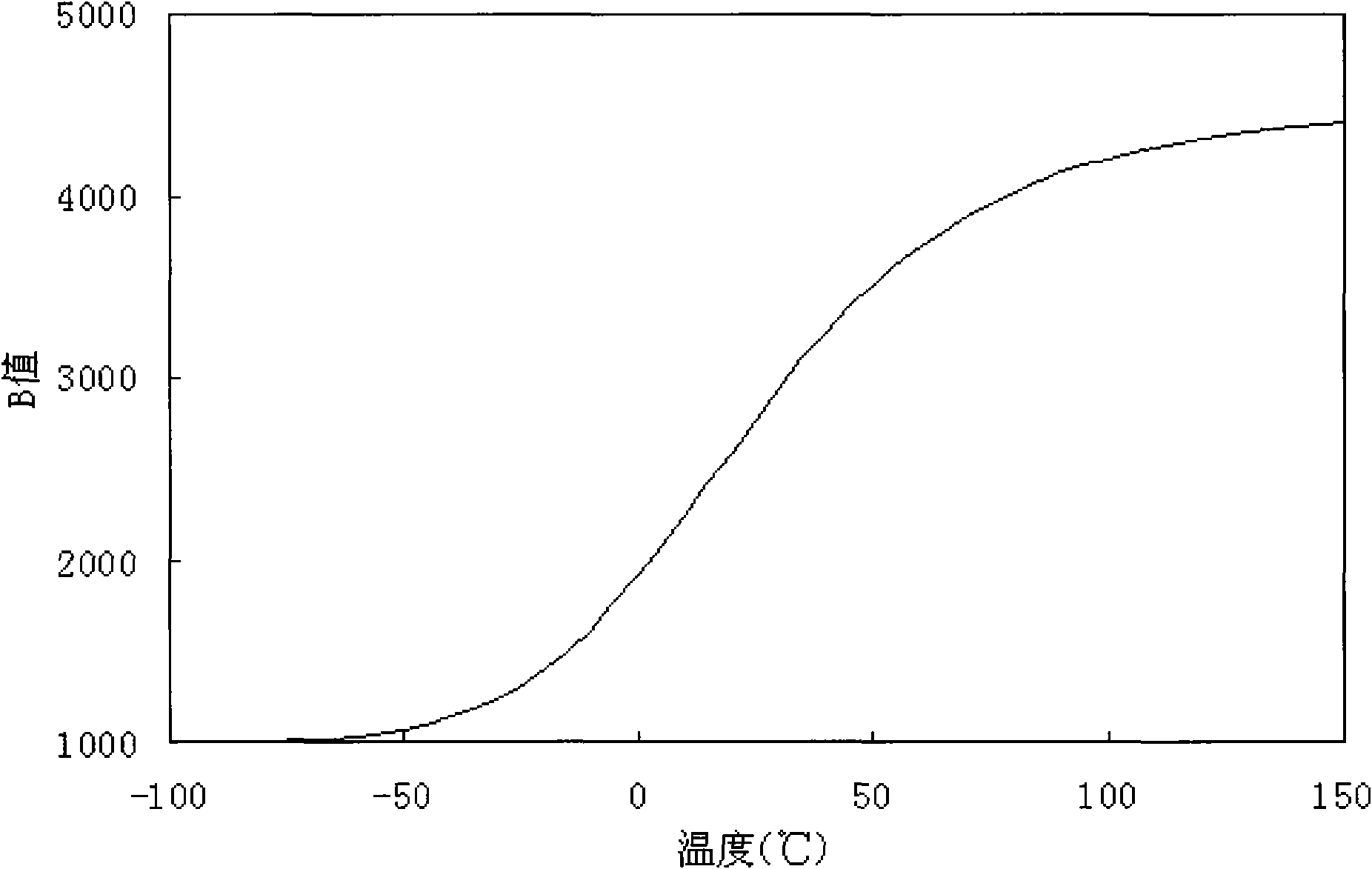

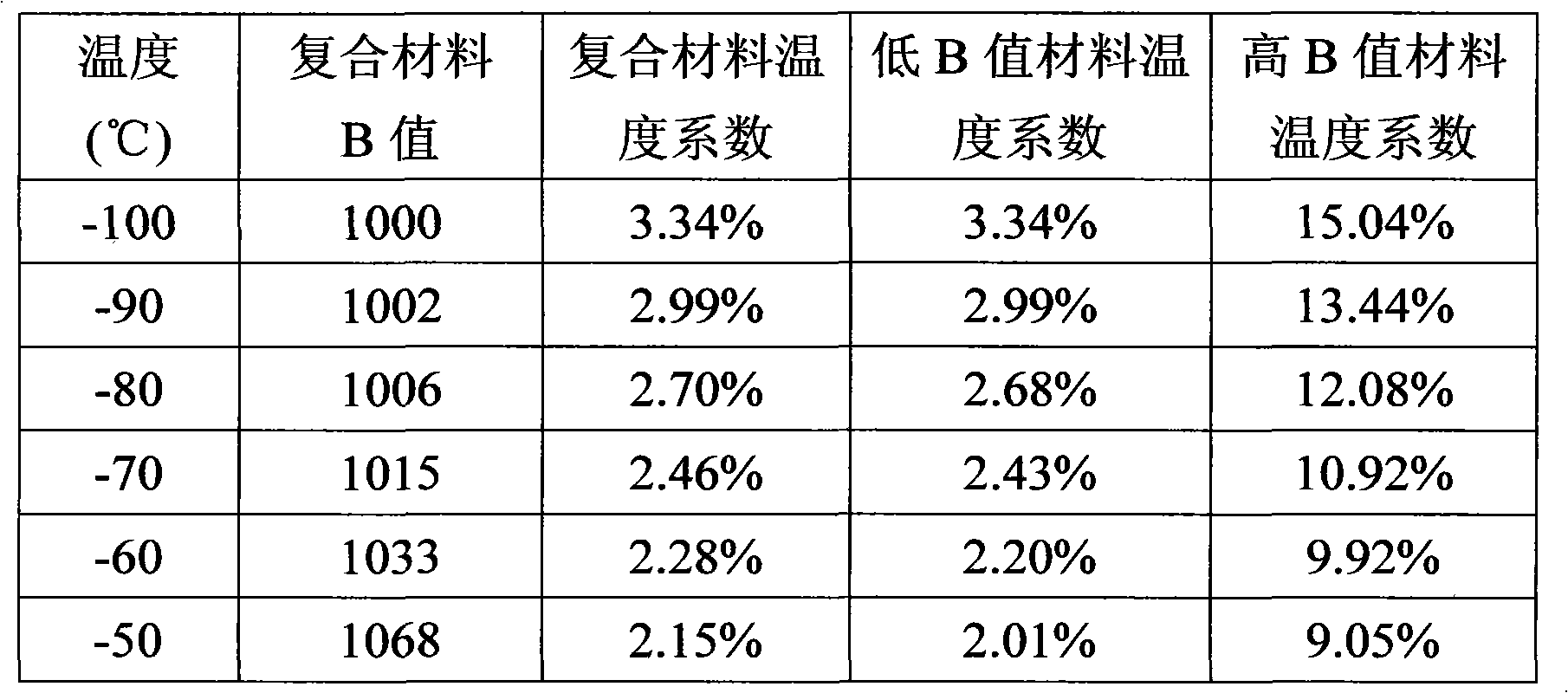

[0038] The green embryo diaphragm includes a high B value green embryo diaphragm with a B value of 4500 and a low B value green embryo diaphragm with a B value of 1000.

[0039] The high B value green membrane is prepared as heat-sensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com