Process for producing budding broad bean crispy granules

A production process, broad bean technology, applied in the production process of germinated broad bean crispy grains, can solve the problems of heat-sensitive material damage, achieve short production cycle, high crispness, and realize the effect of mass production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

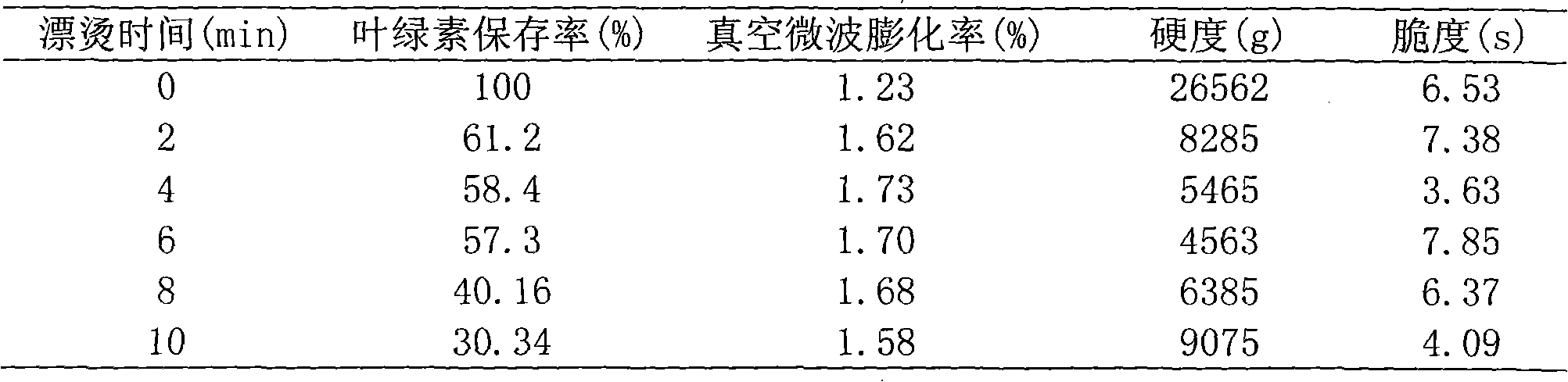

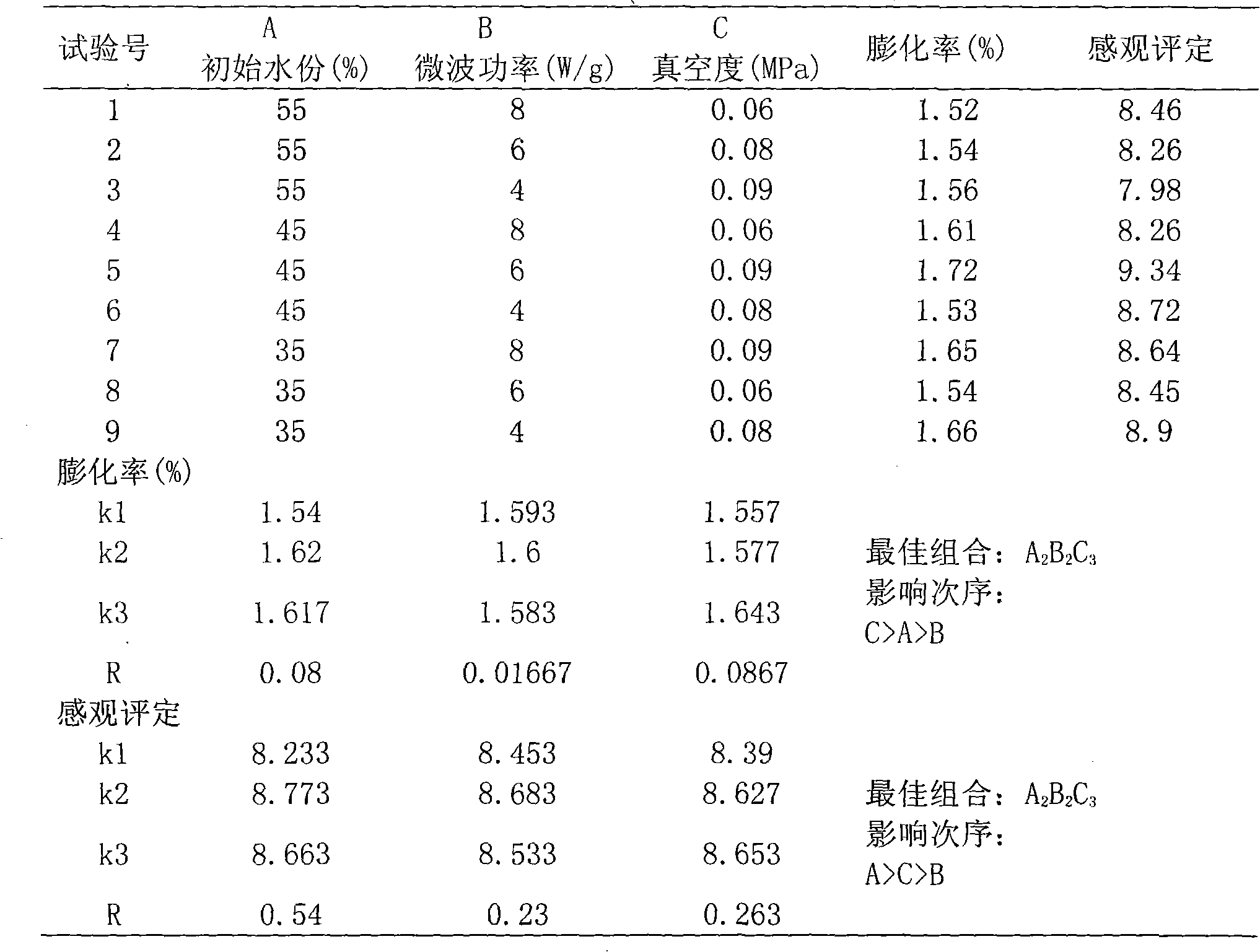

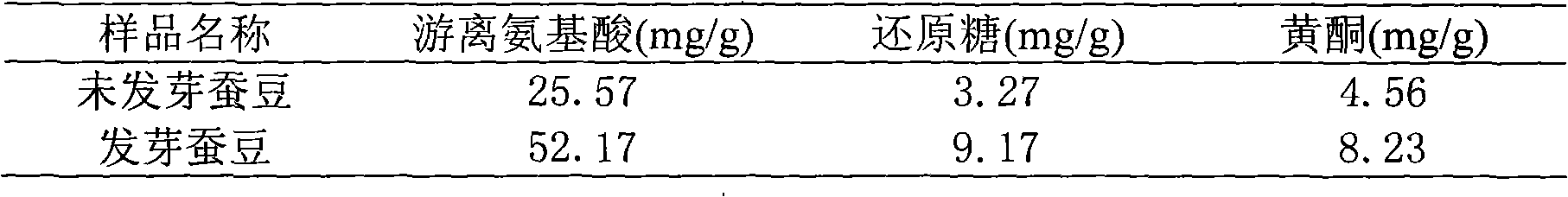

[0026] Choose mature broad bean seeds that are free from diseases and insect pests as raw materials, soak them in water at 55°C for 5 hours, take them out, wrap them with clean gauze, put them in a sealed box, put them in a constant temperature box at 28°C, and take them out after 3 days to get the water content of germinated broad beans at About 60%; wash 1 kg of germinated broad beans and place them at 96-98°C for blanching for 6 minutes, then take them out and cool them; place the blanched germinated broad beans in a -35°C freezer for quick freezing for 6 hours; Broad bean grains are soaked in seasoning (the ratio of liquid adjustment is 1:1) for 3 hours; the soaked germinated broad beans are pre-dried in a hot air drying oven at a drying temperature of 60°C and a drying time of about 1.5 hours. The moisture content is 43.7%; the germinated broad beans after the pre-drying treatment are subjected to a wet treatment, that is, the raw materials after the pre-dried treatment ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com