Water permeable brick capable of adsorbing heavy metal ions

A technology for adsorbing heavy metals and ions, applied in the field of building materials, can solve problems such as pollution, but cannot solve urban traffic problems, and achieve the effect of solving pollution treatment problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

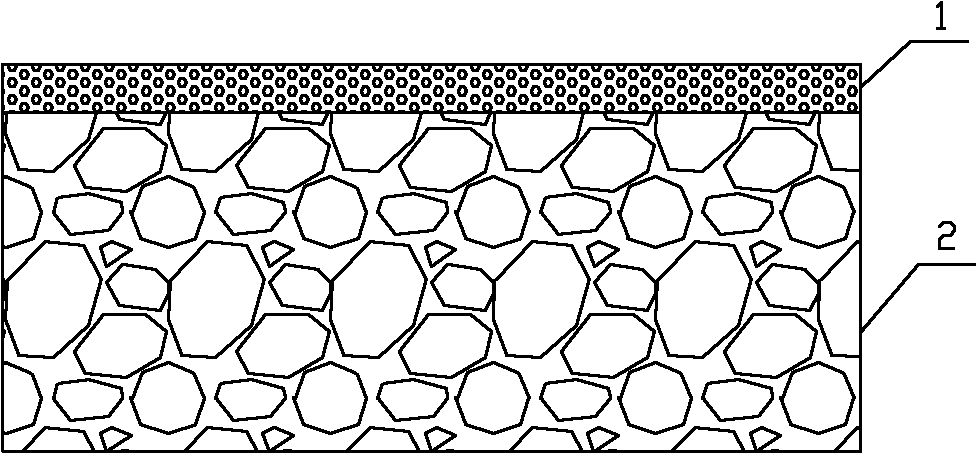

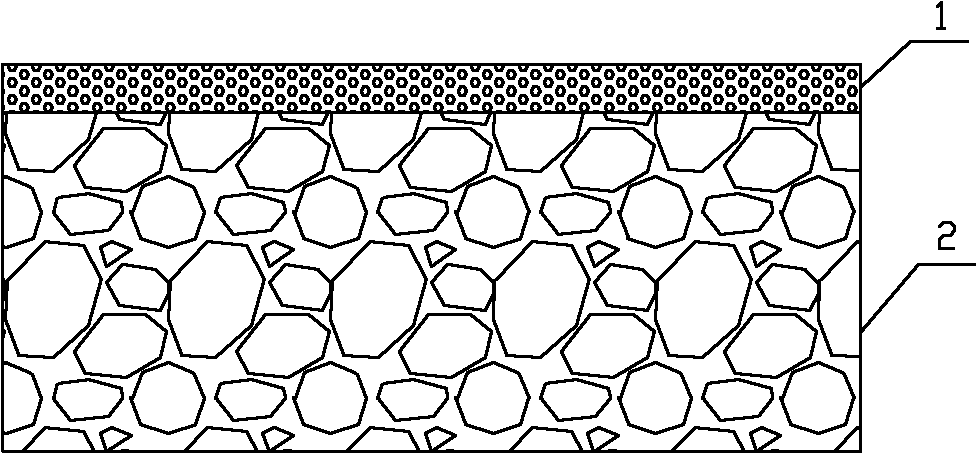

[0013] 1. The thickness of the surface structure is 3mm, and the mixing ratio is: 25 parts of iron-aluminate cement, 60 parts of sand, and 15 parts of steel slag; the thickness of the lower layer is 45 mm, and the mixing ratio is: 18 parts of iron-aluminate cement, 2 parts of zeolite, 56 parts of aggregate and 24 parts of fine aggregate; the water-cement ratio is 0.3.

[0014] Formed in a secondary cloth process and then cured with steam.

[0015] a. The compressive strength of permeable bricks at different ages is:

[0016] age (d)

[0017] b. Adsorption of heavy metal ions:

[0018] To simulate the pollution of heavy metal ions in urban roads in Beijing (much higher than the specified safe concentration), the preparation contains four kinds of heavy metal ions Zn 2+ , Pb 2+ 、Cu 2+ 、Cd 2+ The corresponding concentrations are 79.3mg / L, 88.5mg / L, 17.5mg / L, 13.2mg / L respectively, and the solution passes through the permeable brick at a flow rate of 70L / h.

[0019...

Embodiment 2

[0022] 2. The thickness of the surface structure is 4mm, and the mix ratio is: 30 parts of ferroaluminate cement, 55 parts of sand, and 15 parts of steel slag;

[0023] The thickness of the substructure is 40mm, and the mixing ratio is: ferroaluminate cement: 25 parts, zeolite 5 parts, coarse aggregate 50 parts, fine aggregate 20 parts, and the water-cement ratio is 0.36.

[0024] Formed in a secondary cloth process and then cured with steam.

[0025] a. The compressive strength of permeable bricks at different ages is:

[0026] age (d)

[0027] b. Adsorption of heavy metal ions:

[0028] To simulate the pollution of heavy metal ions in urban roads in Beijing (much higher than the specified safe concentration), the preparation contains four kinds of heavy metal ions Zn 2+ , Pb 2+ 、Cu 2+ 、Cd 2+ The corresponding concentrations are 79.3mg / L, 88.5mg / L, 17.5mg / L, 13.2mg / L respectively, and the solution passes through the permeable brick at a flow rate of 70L / h.

[...

Embodiment 3

[0032] 3. The thickness of the surface structure is 5mm, and the mixing ratio is: 25 parts of iron-aluminate cement, 65 parts of sand, and 10 parts of steel slag; the thickness of the lower layer is 35 mm, and the mixing ratio is: 15 parts of iron-aluminate cement, 1 part of zeolite, 60 parts of coarse aggregate and 24 parts of fine aggregate, with a water-cement ratio of 0.27.

[0033] Formed in a secondary cloth process and then cured with steam.

[0034] a. The compressive strength of permeable bricks at different ages is:

[0035] age (d)

[0036] b. Adsorption of heavy metal ions:

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com