Polycrystalline diamond-hard alloy composite rock breaking button down-the-hole bit and manufacturing process thereof

A polycrystalline diamond and cemented carbide technology, which is used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of short life, material consumption, short life of crushed rock, etc., and achieve high impact resistance, long service life, The effect of high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

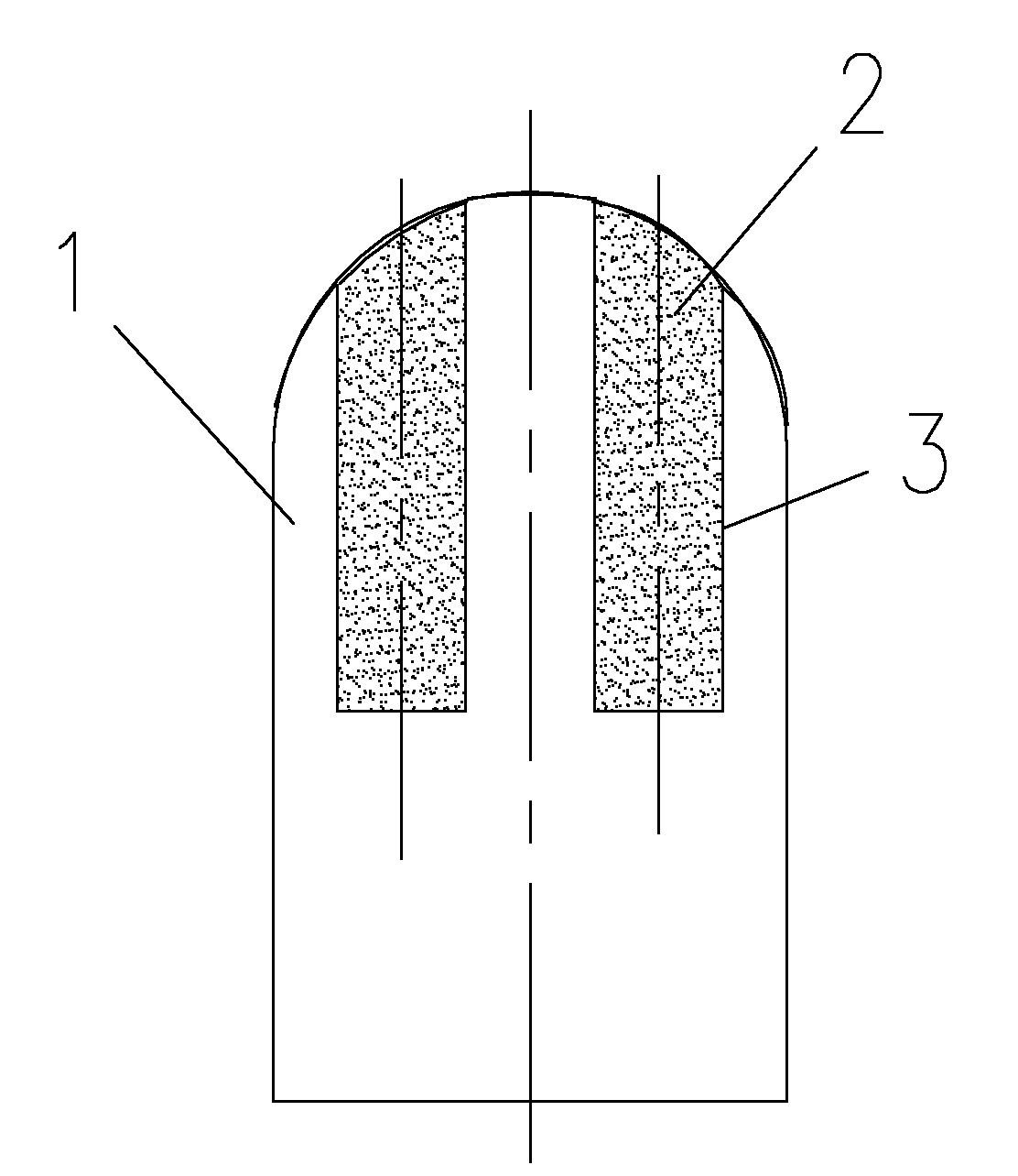

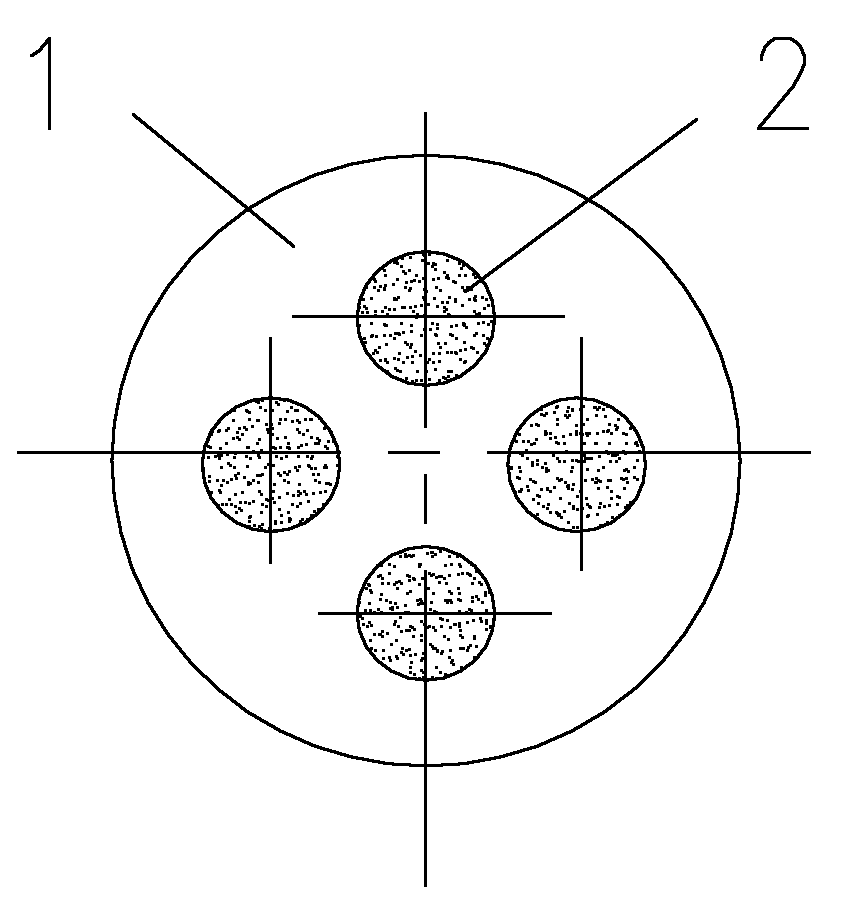

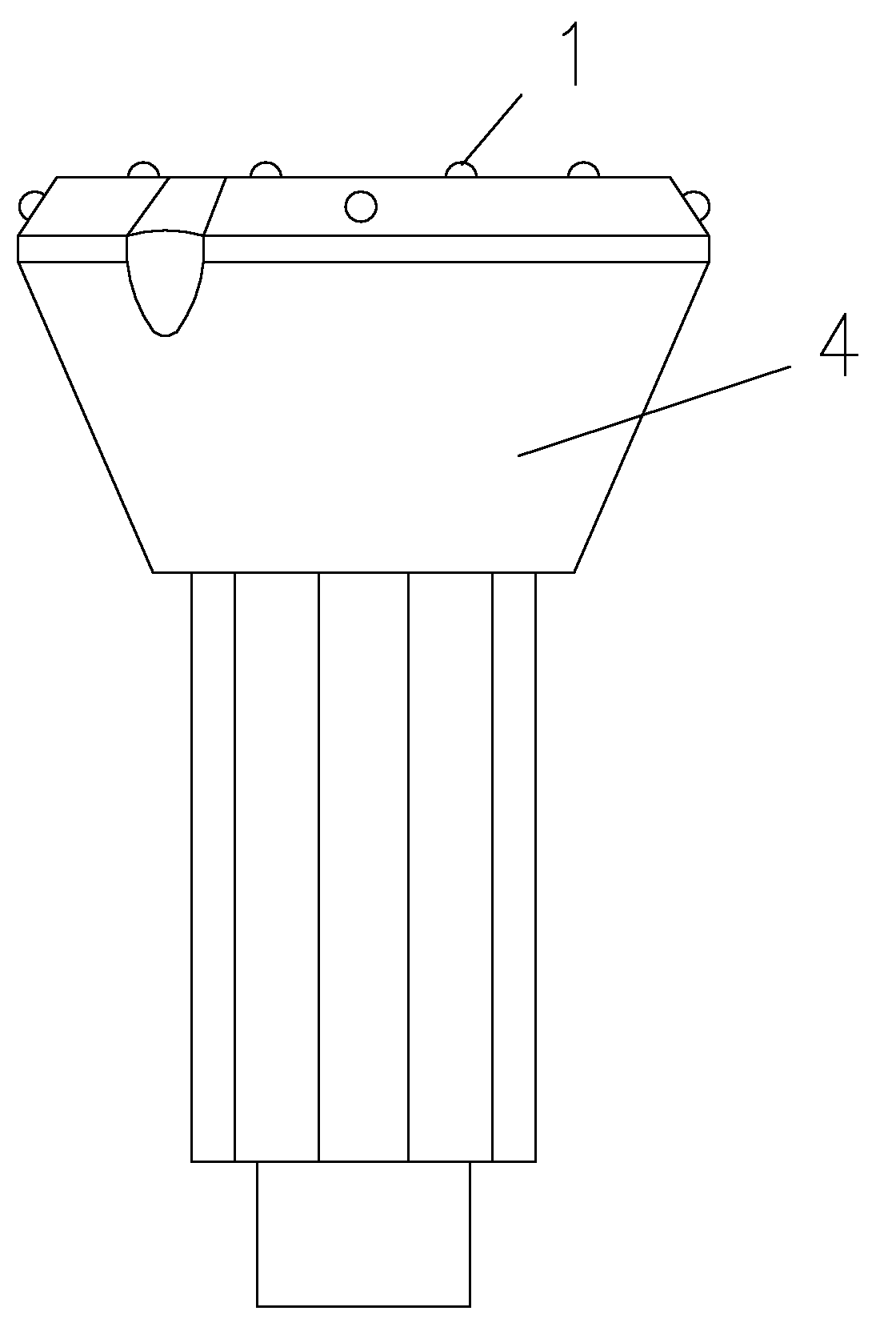

[0016] see figure 1 , figure 2 and image 3 , the steel body 4 of the down-the-hole drill bit is provided with a plurality of cemented carbide button bodies 1, four holes 3 are arranged on the cemented carbide button body 1, and a polycrystalline diamond short cylinder 2 is arranged in each hole 3, The length and diameter of the polycrystalline diamond short cylinder 2 are 1-50mm×φ1-φ30mm.

[0017] The polycrystalline diamond short cylinder 2 is obtained under the conditions of high temperature and high pressure by a synthetic diamond synthesis machine.

[0018] The cemented carbide button main body 1 used is manufactured by a special manufacturer or a cemented carbide manufacturer. The hole 3 in the cemented carbide button main body 1 is pre-formed during the production of the cemented carbide button main body 1, or through Obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com