Longitudinal connecting moment tube and manufacturing method thereof

A radial connection and torque tube technology, applied in the field of transmission, can solve the problem of not meeting the requirements of the torque tube, and achieve the effect of remarkable technical effect, satisfying coaxiality and low heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

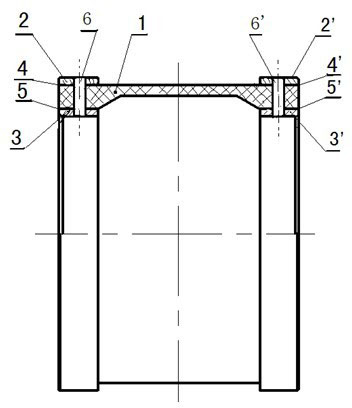

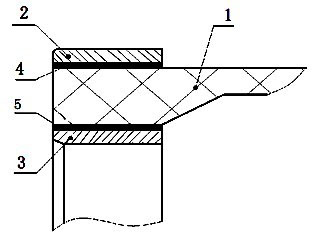

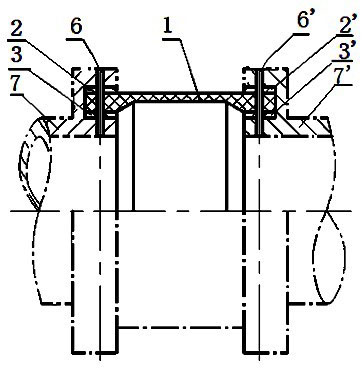

[0025] Example 1: As shown in the figure, the technical solution of the radial connection torque tube of the present invention is: a radial connection torque tube, which has a cylinder 1; the two ends of the cylinder 1 have an outer ring and an inner ring respectively, namely: One end is the outer ring 2, and the inner ring 3, and the other end is the outer ring 2' and the inner ring 3'; there is a low-temperature adhesive layer between the outer ring and the inner ring at both ends of the cylinder body 1 and the cylinder body, that is, : One end is the low-temperature adhesive layer 4 between the outer ring 2 and the cylinder 1, and the low-temperature adhesive layer 5 between the inner ring 3 and the cylinder 1; the other end is the low-temperature adhesive layer between the outer ring 2' and the cylinder 1. The adhesive layer 4', the low-temperature adhesive layer 5' between the inner ring 3' and the cylinder body 1; coaxial; as image 3 As shown, the two ends of the cyl...

Embodiment 2

[0029] Example 2: The difference from the above-mentioned embodiment 1 is that the material of the cylinder body 1 is a plastic with high strength and low heat leakage. Inner ring 3, 3' is made of stainless steel, and outer ring 2, 2' is also made of stainless steel. The low-temperature adhesive is JSF-6 low-temperature adhesive from Shanghai Zhenhua Paint Factory, or Stycast2850GT.

Embodiment 3

[0030] Example 3: The difference from the above-mentioned embodiment 1 is that the inner ring 3, 3' and the outer ring 2, 2' are circular rings, and the inner surface of the inner ring 3, 3' and the inner surface of the outer ring 2, 2' are used for strengthening and Grooves for cylinder binding force and improved torsion resistance. The non-metallic composite material of the barrel 1 is selected from glass fiber composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com