Pulverized coal sampling exhaust gas recycling device

A recovery device and pulverized coal technology are used in the recovery of spent gas in rapid sampling systems, and in the field of spent gas recovery devices for pulverized coal sampling, which can solve problems such as harsh working environment and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

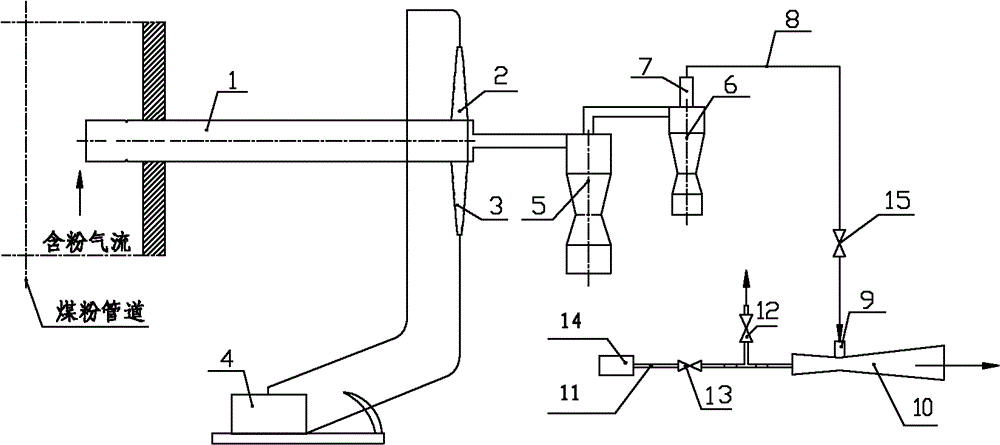

[0020] figure 1 It is a schematic diagram of a flat-head constant-velocity pulverized coal sampling system. The first-stage separator 5 is connected with the sampling gun 1 through threads, and the sampling tubes and pressure nozzles 2 and 3 of the sampling gun 1 are connected with the micromanometer 4; the compressed air source 14 and the shut-off valve 13 is connected to one end of the aspirator 10 through the compressed air introduction pipe 11, and the other end of the aspirator 10 is connected to the sampler discharge pipe 16; Connect with the outlet pipe 7 of the secondary separator;

[0021] The invention relates to a exhaust gas recovery device for a pulverized coal sampler, which is particularly suitable for recovery of exhaust gas in a pulverized coal flow constant-velocity sampling system of a power plant boiler direct-blown pulverization system, and aims at protecting the environment and improving on-site working conditions.

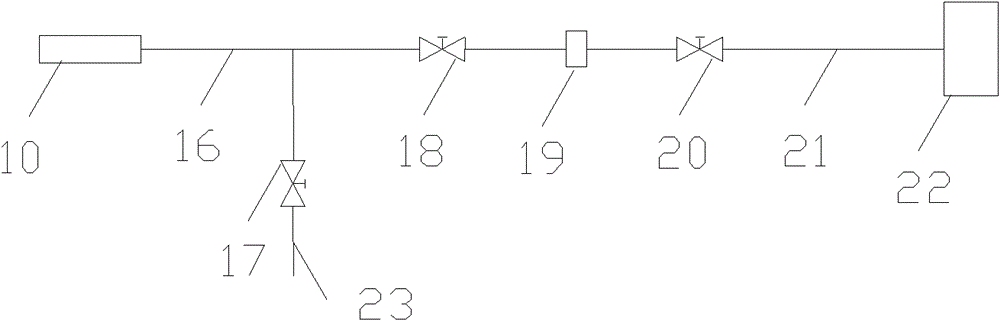

[0022] refer to figure 2 , the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com