Optical fiber grating acceleration sensor and test method thereof

A technology of acceleration sensor and fiber grating, which is applied in the direction of using inertial force for acceleration measurement, etc., can solve the problems of small cross-sectional area of fiber grating, unbalanced initial state, and easy breakage, etc., to expand the range of strain range, improve sensitivity, increase non-linear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

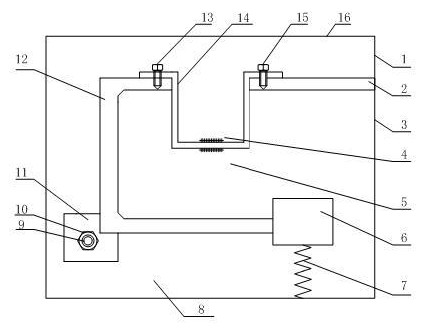

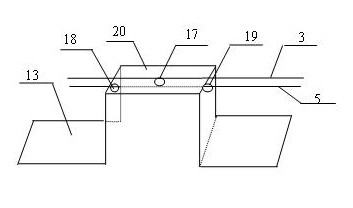

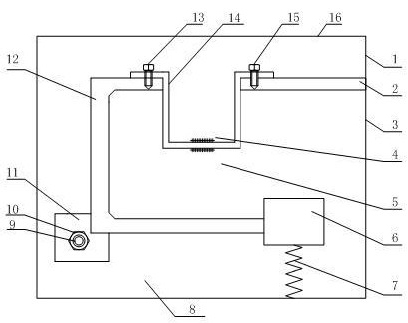

[0026] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

[0027] Such as figure 1 As shown, a fiber grating acceleration sensor includes a U-shaped housing 1, a rigid beam 2, a first fiber grating 4, a second fiber grating 5, a mass 6, a spring 7, a damping fluid 8, a slot 11, and a concave lever 12 , folding arched beam 14, sealing cover 16, the opening end of U-shaped housing 1 is provided with sealing cover 16, on the inner wall of U-shaped housing 1, connects one end of rigid beam 2, and the other end of rigid beam 2 is fixedly connected with folding arched beam 14, folding The arched beam 14 is fixedly connected with the concave lever 12, the concave lever 12 fixed on the slot 11 is connected to the mass block 6, the mass block 6 is connected to the inner wall of the housing 1 through the spring 7, and the first optical fiber is respectively arranged on the folded arched beam 14 The grating 4, the second fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com