Cam follower for rocker arm, and cam follower device

A technology of cams and moving parts, applied in the field of cam followers for rocker arms, can solve the problems of shortening the life of rolling bearings, supplying lubricating oil to rolling bearings, etc., and achieve the effect of improving the life of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

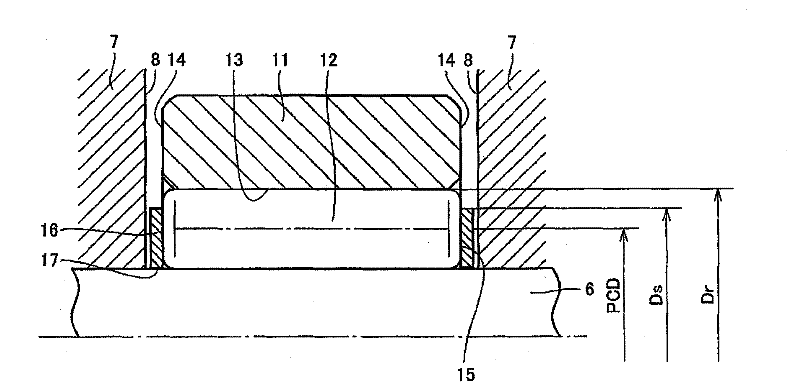

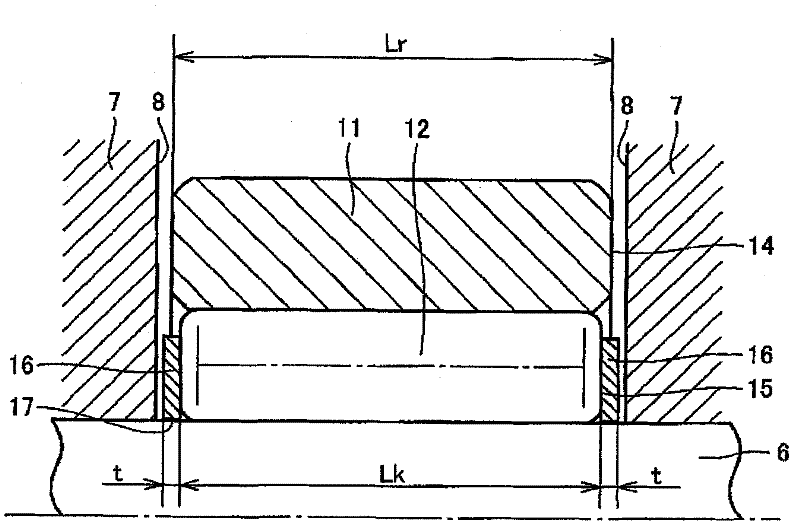

[0028] Hereinafter, embodiments of the present invention will be described in detail based on Examples shown in the drawings.

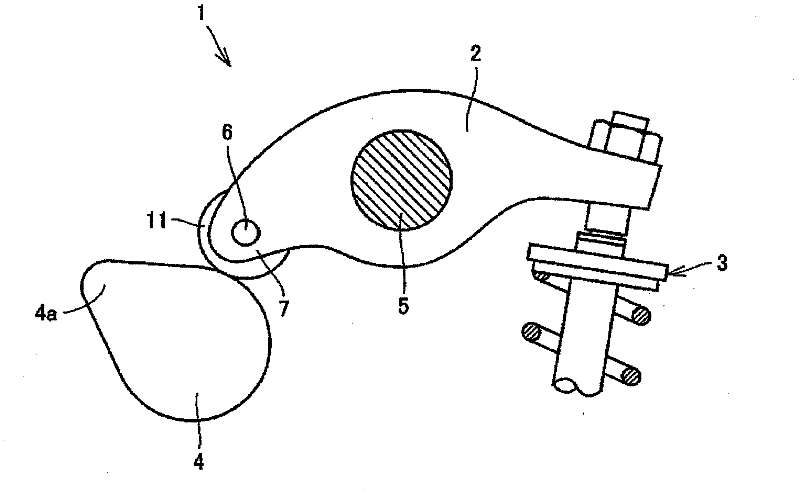

[0029] figure 1 It is a front view showing the movable valve mechanism incorporating the cam follower of the first embodiment of the present invention. The movable valve mechanism 1 is an engine part of a motor vehicle, and is equipped with: a rocker arm 2 supported by a shaft 5 to be able to swing; it is arranged at one end of the rocker arm 2, and the intake and exhaust of the engine combustion chamber are performed by the swing of the rocker arm 2 valve 3; a support shaft 6 arranged at the other end of the rocker arm 2; an outer ring 11 rotatably supported by the outer periphery of the support shaft 6; a cam 4 fixed to a camshaft (not shown) and having an eccentric portion 4a .

[0030] The movable valve mechanism 1 configured as described above transmits the rotation of a crankshaft (not shown) of the engine to a camshaft (not shown) via a timin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com